When sourcing terminal blocks for electrical systems, one of the most important decisions is choosing betweenscrew-typeandpush-inconnection designs. Both are widely used in industrial equipment, control cabinets, and electronics, but each has distinct advantages depending on the application.

AtNingbo Zhongbo Photovoltaic Technology Co., Ltd., we help global customers select the right terminal block solutions for their systems. This article breaks down the pros and cons of screw vs. push-in terminal blocks—and how to decide which type is best for your next project.

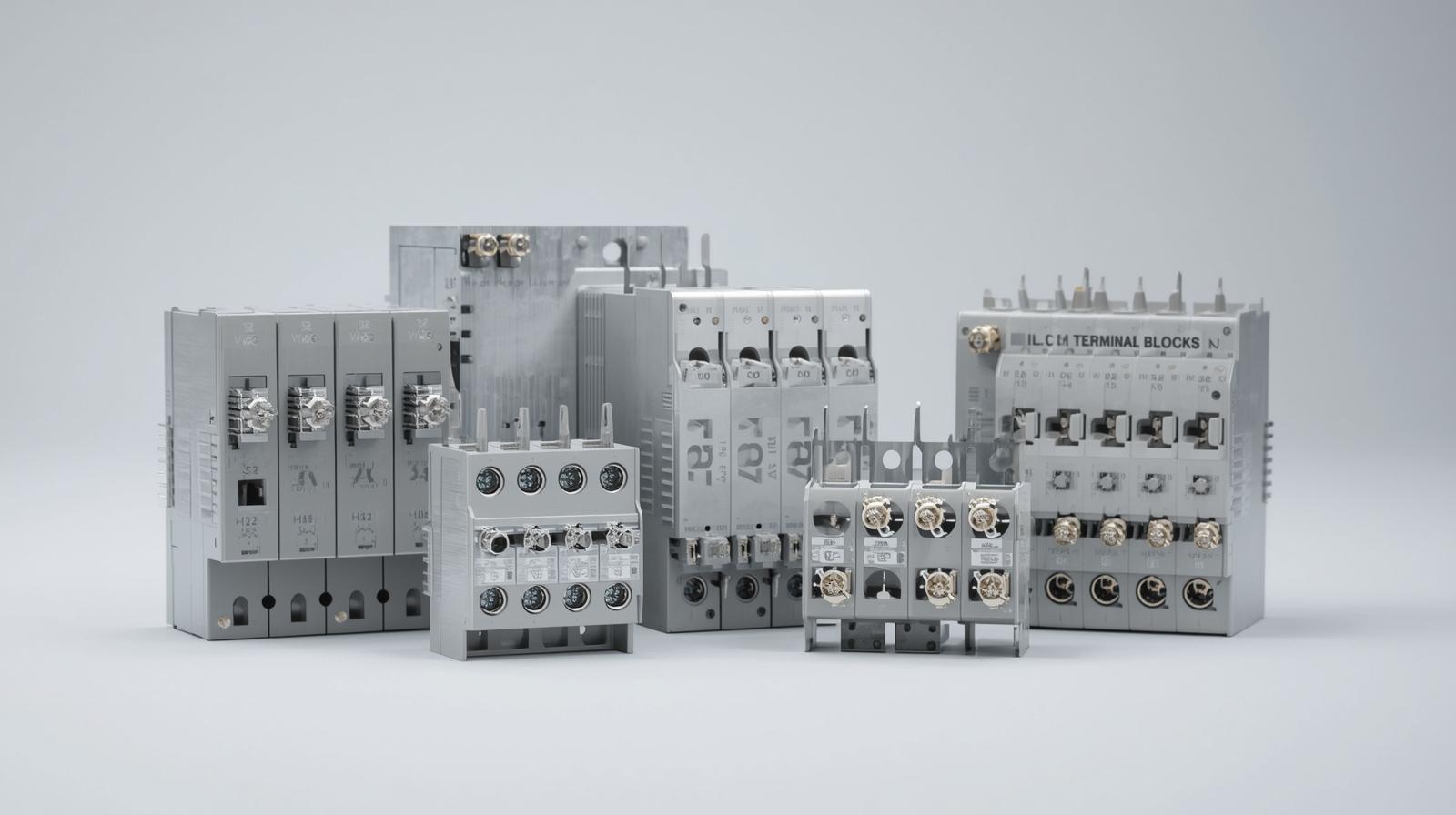

🔩1. Screw Terminal Blocks: Traditional, Reliable, and Versatile

Screw terminal blocks use a metal screw to clamp down on a stripped wire, making them one of the most common connection types in the electrical industry.

✅Advantages:

-

Compatible with solid and stranded wires

-

Secure mechanical connection

-

Ideal for high-vibration environments

-

Proven performance in high-voltage or high-current applications

At Zhongbo, our best-selling ZB128 and ZB350 series screw terminal blocks are trusted by panel builders, machinery OEMs, and electrical wholesalers for their rugged design and stable connection.

✅Use Cases:

-

Power distribution panels

-

HVAC systems

-

Industrial equipment

-

Motor control units

⚡2. Push-In Terminal Blocks: Fast Wiring and Time Savings

Push-in terminal blocks allow solid wires (or ferruled stranded wires) to be inserted directly without tools, making them a go-to choice for automation and modern control systems.

✅Advantages:

-

Tool-free wire insertion

-

Saves up to 70% wiring time

-

Consistent contact pressure via spring mechanism

-

Clean and professional finish

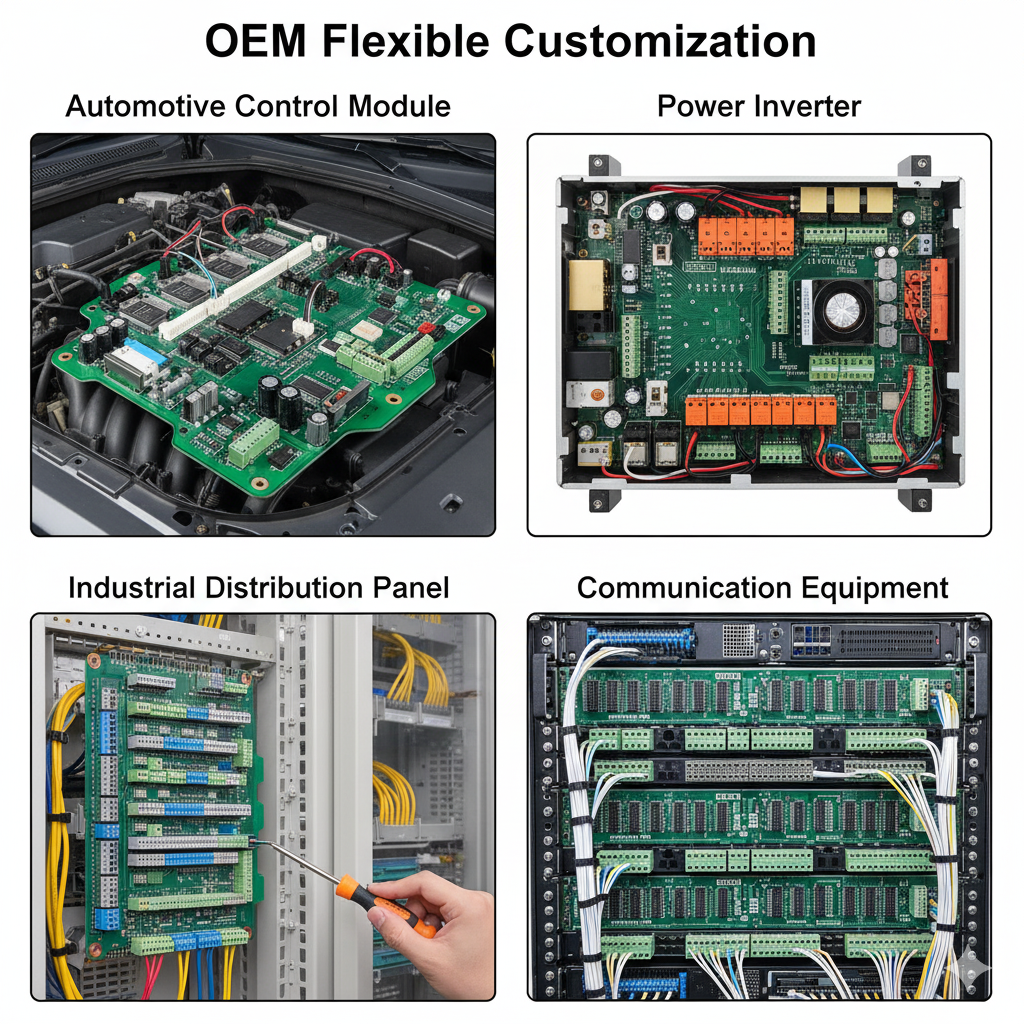

Zhongbo offerscustom OEM push-in terminal block solutions, ideal for fast-paced assembly lines and applications where speed and ease of use are priorities.

✅Use Cases:

-

Modular control cabinets

-

Building automation

-

Low-voltage signal wiring

-

Electronics and sensor networks

🛠️3. Which One Should You Choose?

| Feature | Screw Terminal Block | Push-In Terminal Block |

|---|---|---|

| Wire Type Compatibility | Solid & Stranded | Solid or Ferruled Stranded |

| Installation Speed | Moderate | Fast |

| Tool Requirement | Screwdriver | No Tools (for push-in) |

| Vibration Resistance | High | Moderate |

| Cost | Generally Lower | Slightly Higher (OEM) |

👉 If you prioritize reliability and heavy-duty usage, choosescrew-type blockslikeZB128.

👉 If you're focused on speed and streamlined assembly, choosepush-in blocks, especially forOEM panel manufacturing.

🔧Zhongbo Offers OEM & Bulk Terminal Block Solutions

Whether you choose screw or push-in, Zhongbo provides bulk manufacturing, private label customization, and international certification (UL, CE, RoHS) for all our terminal blocks. With over 14 years of export experience, we support clients in North America, Europe, and the Middle East.

📞Contact Zhongbo for Product Selection and Pricing

Need help choosing the right terminal block for your application? Let our team assist you with samples, specs, and quotes.

📍Company:Ningbo Zhongbo Photovoltaic Technology Co., Ltd.

📧Email:chunni@nbzhongbo.com

📞Phone:+86-18067551718

🌐Website: www.nbzbo.com