OEM Flexibility in PCB Mounted Terminal Manufacturing

In the rapidly evolving electronics and energy sectors, OEM flexibility has become a key differentiator for PCB mounted terminal manufacturers. End users in automotive, industrial automation, and renewable energy are no longer satisfied with generic designs. They demand terminals that meet their specific performance, compliance, and integration requirements.

Customization Beyond Dimensions

Traditional terminals often follow standard pin spacing and housing formats. However, OEM projects frequently require:

-

Tailored pitch and configuration to fit compact PCBs in high-density boards.

-

Material flexibility, such as high-temperature polymers for engine control modules or reinforced plastics for industrial cabinets.

-

Custom plating options, from tin to gold, to optimize conductivity and corrosion resistance under different operating environments.

This flexibility allows OEM partners to reduce design compromises while ensuring reliable electrical connections in diverse conditions.

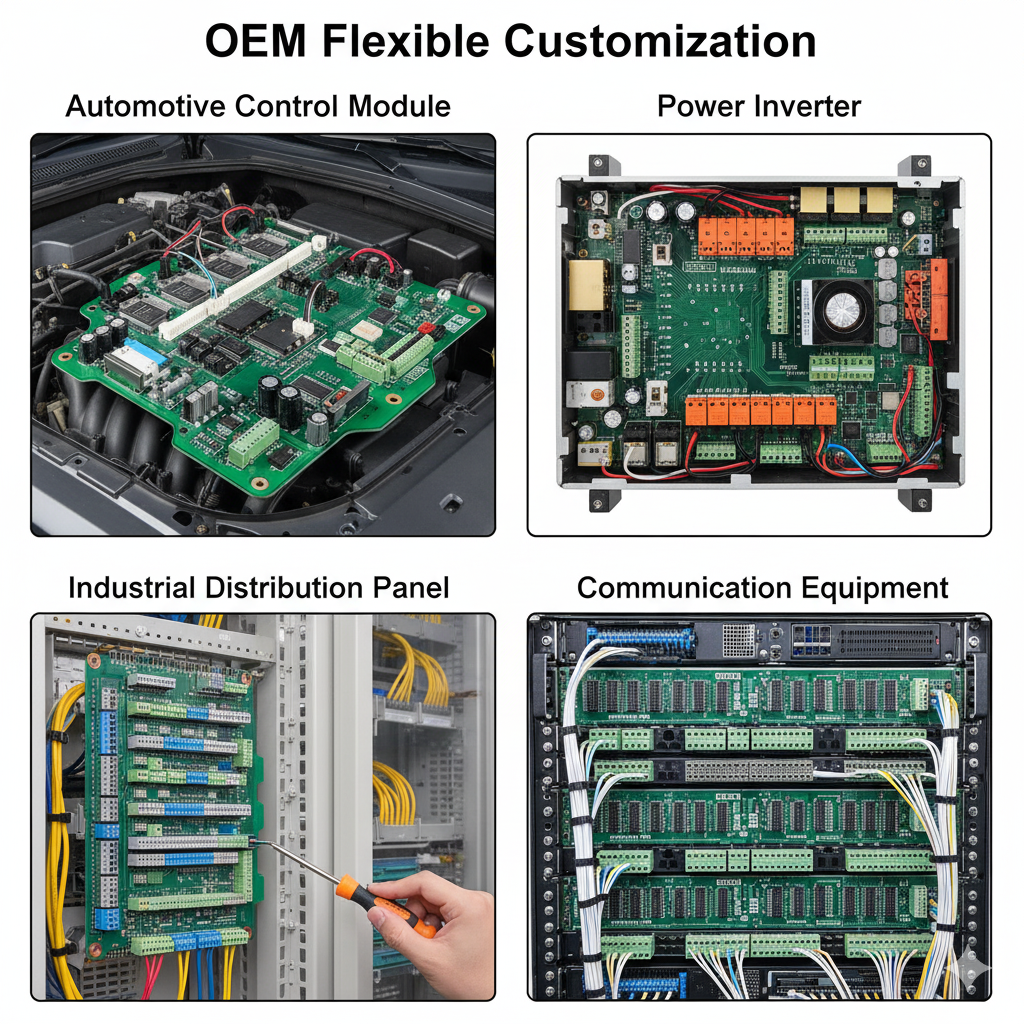

Application-Driven OEM Adjustments

The need for customization stems directly from the industries that rely on these components:

-

Automotive Electronics: Modules near the engine bay require vibration-resistant and high-temperature connectors.

-

Industrial Automation: OEM solutions focus on safety certifications, modular assembly, and quick field replacements.

-

Renewable Energy Systems: Terminals must handle fluctuating voltages and offer surge resilience for solar and wind applications.

By aligning designs with application-specific challenges, OEM manufacturing delivers real-world reliability that off-the-shelf products cannot match.

Advantages of OEM Flexibility

| OEM Capability | Buyer Benefit | Application Impact |

|---|---|---|

| Custom pitch and housing | Better fit for compact or large PCBs | Automotive ECUs, telecom boards |

| Material selection options | Fire resistance, chemical durability | Industrial cabinets, renewable inverters |

| Surface plating variations | Enhanced conductivity, anti-corrosion | Marine, outdoor energy systems |

| Scalable production models | Cost control for low- and high-volume runs | Startups to global equipment suppliers |

This structured flexibility ensures that clients can achieve compliance and performance without overpaying for features they don’t need.

Buyer FAQs on OEM PCB Terminals

Q1: How does OEM flexibility reduce long-term costs?

By tailoring terminals to precise requirements, buyers avoid over-engineering and reduce warranty claims from system failures.

Q2: What certifications can be met through OEM design?

UL, CE, and IEC standards can be incorporated into the design phase, ensuring global compliance from the start.

Q3: Can OEM solutions support both low and high production volumes?

Yes, manufacturers like ZhongBo adapt processes to support pilot runs for startups and large-scale supply for established brands.

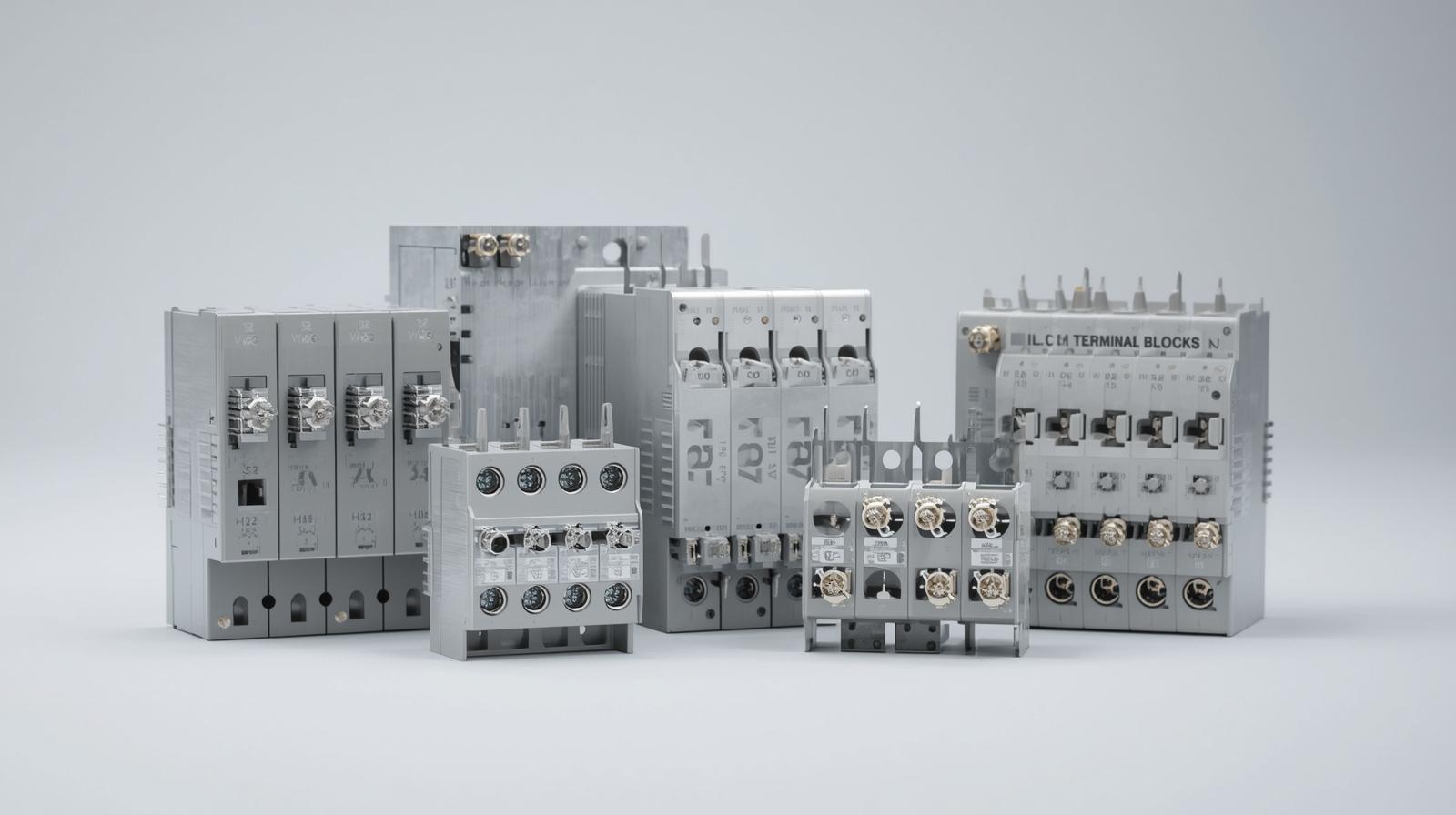

ZhongBo’s OEM Advantage

We specialize in delivering OEM flexibility in PCB mounted terminal manufacturing. Our capabilities include:

-

Full-spectrum design services for custom PCB terminals.

-

Certified materials and plating options for varied industries.

-

Scalable production aligned with both niche and global markets.

-

Proven track record in automotive, renewable energy, telecom, and industrial automation.

For enterprises seeking tailored solutions, ZhongBo offers more than just products—we deliver partnerships built on engineering precision and supply chain reliability. Learn more on our homepage or contact us directly via our contact page.