Barrier Terminal Block Exporter: Building Safer and Smarter Electrical Networks

Understanding the Global Demand for Safer Connections

In industrial electrical systems, safety and scalability depend on the smallest details. Barrier terminal blocks ensure that current flow remains stable, wires stay protected, and accidental shorts are prevented. As international infrastructure expands—from renewable energy grids to automated factories—the demand for reliable, export-grade terminal blocks continues to grow. Many projects struggle with issues like inconsistent insulation, improper spacing, or connector fatigue after prolonged vibration, which can result in costly downtime.

Leading exporters address these challenges by introducing reinforced materials, precision spacing, and consistent design quality to meet IEC, UL, and CE standards. According to the International Electrotechnical Commission (IEC), global safety requirements for power distribution systems have increased by over 30% in the past decade, emphasizing the need for certified products.

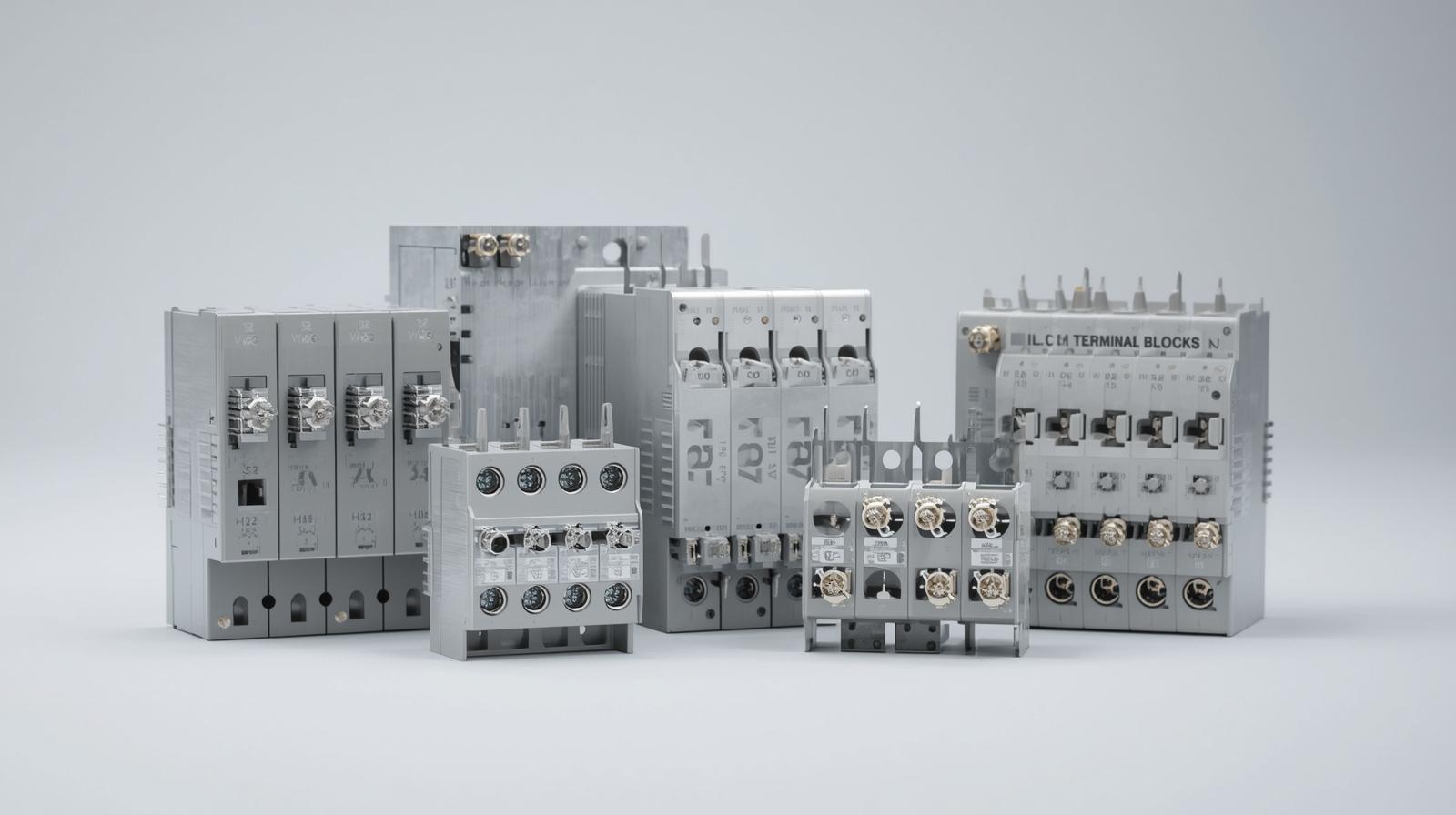

Engineering Principles Behind Barrier Terminal Blocks

Barrier terminal blocks are engineered with a focus on mechanical stability, insulation integrity, and user protection. The key components—housing, screws, and conductive parts—undergo strict testing for torque, dielectric strength, and flame resistance.

Their design minimizes cross-wiring risks and supports clear polarity identification, making them ideal for complex wiring environments such as switchboards or inverter systems.

Key design benefits include:

-

Fixed barriers between terminals preventing short-circuits

-

High-temperature endurance for industrial-grade wiring

-

Anti-vibration screws ensuring long-term mechanical reliability

-

Simplified wiring access supporting both manual and automated assembly

Comparison: Standard vs. Export-Grade Barrier Terminal Blocks

| Feature | Standard Terminal Blocks | Export-Grade Barrier Terminal Blocks |

|---|---|---|

| Compliance | Local or limited standards | Certified for IEC, UL, CE, RoHS |

| Material | Basic thermoplastics | Flame-retardant PA66 or PC alloys |

| Mechanical Stability | Moderate | Anti-vibration tested for transport use |

| Current Range | <15A | Up to 40A continuous current |

| Application Scope | Domestic use | Industrial automation, power grids, renewable energy |

| Traceability | Manual batch records | Digital quality tracking and test logs |

Applications Across Industries

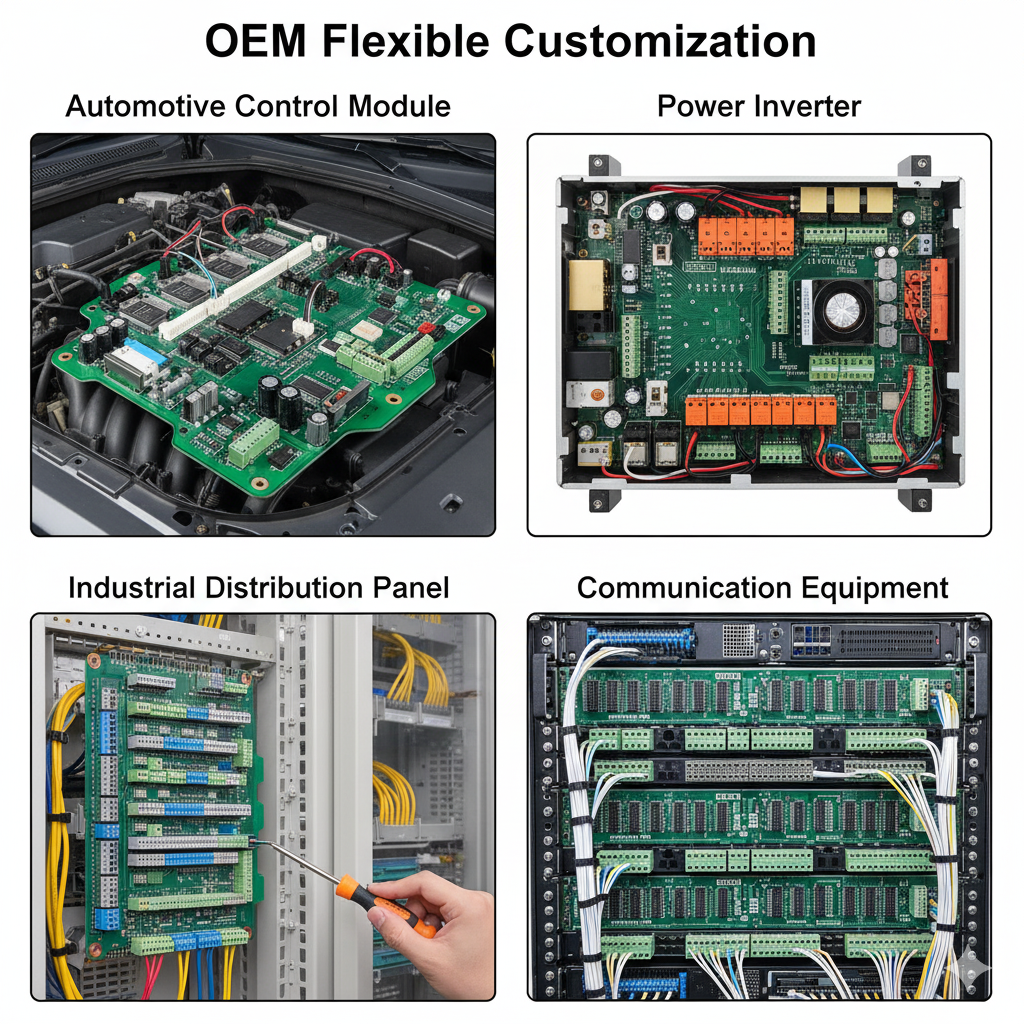

Export-grade barrier terminal blocks are integral to multiple high-demand sectors:

-

Power Distribution Systems – Used in low-voltage cabinets and switchgear to ensure circuit separation and overload protection.

-

Renewable Energy Plants – Connect photovoltaic panels, inverters, and control systems with consistent current flow even under heat and humidity.

-

Transportation and Rail – Provide durable, vibration-resistant connections for signaling and electrical control systems.

-

Automation Lines – Enable fast wiring during production equipment setup and reduce downtime during maintenance.

Each of these sectors values durability, easy inspection, and compliance documentation, making certified exporters a critical part of the global supply chain.

Questions Buyers Often Ask

Q1: How does ZhongBo ensure export-level quality control?

All barrier terminal blocks are manufactured under ISO9001:2015 systems. Each batch undergoes dielectric, pull-force, and temperature cycling tests before shipment.

Q2: What export standards are met?

ZhongBo’s products comply with IEC 60947, UL 1059, and CE safety certifications, verified through third-party testing.

Q3: Can terminal blocks be customized for specific environments?

Yes. ZhongBo supports OEM and ODM customization, including screw type, spacing, and housing material—tailored to conditions like high temperature, outdoor exposure, or vibration-prone machinery.

Global Reliability Backed by Engineering Strength

ZhongBo has developed a reputation for delivering high-current, flame-retardant, and precision-engineered barrier terminal blocks trusted by power, transport, and automation partners across continents. Its integrated production—from metal processing to insulation molding—ensures both cost efficiency and consistent quality.

By focusing on long-term reliability and compliance, ZhongBo enables global manufacturers to reduce maintenance costs while improving system safety.

For detailed product specifications and partnership opportunities, visit ZhongBo’s homepage or contact the technical team directly via the contact page.