Precision Meets Customization: Inside the 3.5mm Screw Terminal Block OEM Manufacturing Process

Miniaturization in industrial electronics demands more from every component—greater precision, stronger insulation, and longer endurance within smaller geometries. The 3.5mm screw terminal block meets these challenges by offering compact, reliable, and customizable wiring interfaces for OEM electrical systems.

This article dissects how 3.5mm screw terminal block OEM manufacturing combines advanced materials, high-precision tooling, and global compliance standards to serve automation, energy control, and instrumentation applications.

Engineering Logic Behind the 3.5mm Screw Terminal Block

The 3.5mm pitch design represents a balance between density and electrical safety. In low-voltage PCB environments, it maintains sufficient creepage and clearance distance while enabling space-efficient wiring.

Key structural features include:

-

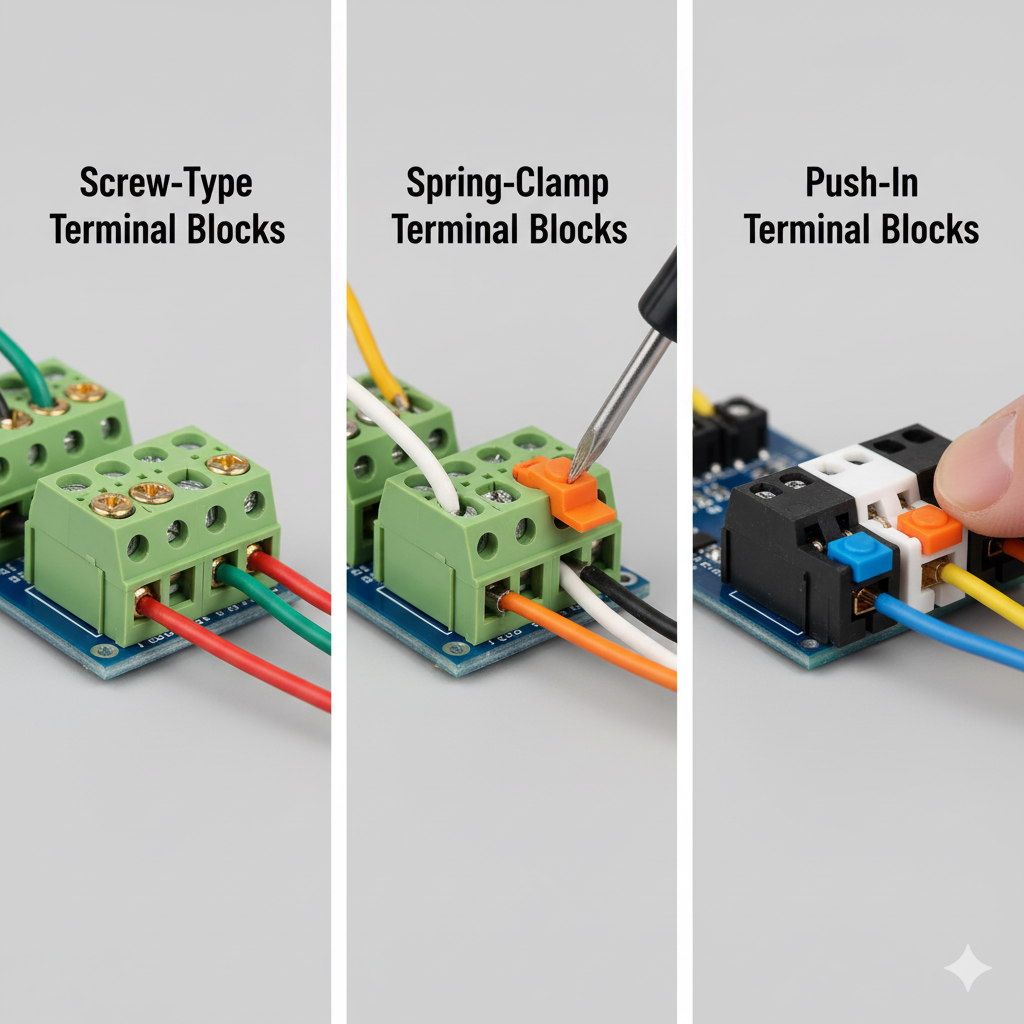

Screw clamp mechanism for stable torque retention.

-

3.5mm pitch supporting compact PCB layouts and modular wiring.

-

Flame-retardant PA66 housing for insulation and heat resistance.

-

Rated voltage: 125V–250V depending on configuration.

-

Current capacity: Up to 8A, suitable for low- and medium-power circuits.

These design choices allow engineers to integrate terminal blocks into lighting controllers, automation panels, and small power converters without compromising connection integrity.

Material Selection and Electrical Integrity

Each 3.5mm screw terminal block is engineered from UL-rated materials designed to withstand temperature cycles, torque stress, and electrical load.

| Component | Material | Engineering Function |

|---|---|---|

| Housing | PA66 UL94 V-0 | Flame retardant, insulation, mechanical strength |

| Contacts | Brass (tin or nickel plated) | Conductivity, anti-corrosion, low resistance |

| Screws | M2.0–M2.5 carbon steel | Torque retention, vibration resistance |

| Plating Thickness | ≥2μm | Improved contact reliability and oxidation control |

Manufacturers maintain tight dimensional tolerance (±0.02mm) during molding, ensuring alignment consistency between screw and conductor. Each unit undergoes dielectric strength tests up to 1.5kV and contact resistance validation (<20mΩ) to meet OEM quality expectations.

Precision Manufacturing and Quality Control

OEM production of 3.5mm screw terminal blocks demands a fully automated process combining mechanical precision and electrical verification.

-

Micro-Injection Molding: Produces consistent insulation barriers with uniform wall thickness.

-

Robotic Assembly: Ensures precise placement of contacts and screws to eliminate offset.

-

Torque Calibration Systems: Validate screw tension under repetitive load cycles.

-

Plating and Coating Control: Automated bath management ensures plating uniformity.

-

100% Continuity Testing: Confirms electrical performance of every finished batch.

These process controls guarantee that every OEM shipment performs identically—critical for long-term partnerships with automation, lighting, and energy equipment manufacturers.

Compliance and Certification Framework

Export-ready OEM products must conform to multiple international standards:

-

UL1059: Verifies insulation resistance, mechanical torque, and dielectric strength.

-

IEC60947-7-1: Specifies electrical connection safety for low-voltage applications.

-

RoHS / REACH: Ensures non-toxic, environmentally compliant materials.

-

ISO9001: Validates process quality and traceability throughout production.

Compliance integration at the factory level allows OEM clients to include certification documentation directly in their device or system approval packages.

Comparative Engineering: 3.5mm vs. 5.08mm Screw Terminal Blocks

| Specification | 3.5mm Screw Type | 5.08mm Screw Type |

|---|---|---|

| Pitch Size | 3.5mm | 5.08mm |

| Voltage Rating | 125–250V | 300–600V |

| Current Capacity | 6–8A | 15–24A |

| Density | High | Moderate |

| Application | Compact PCB and control wiring | Power and industrial panels |

The 3.5mm variant is ideal for signal-level or low-power distribution, particularly in devices where PCB real estate is limited but mechanical strength remains crucial.

OEM Customization: Matching Design with Functionality

OEM terminal block projects often require adjustments to match product-specific environments.

Manufacturers offer flexible configuration options to align with mechanical layout, branding, and wiring logic:

| Customization Type | Description | Engineering Value |

|---|---|---|

| Pole Configuration | 2–24 poles per block | Modular wiring flexibility |

| Color Coding | Custom housing colors | Easy wiring identification |

| Logo Engraving | OEM branding | Market differentiation |

| Pitch Modification | 3.5mm, 3.81mm, 5.08mm | PCB design adaptability |

| Mounting Orientation | Vertical / horizontal / 45° | Fit diverse board layouts |

OEM clients benefit from direct mold ownership, ensuring consistency across long production runs and guaranteeing supply chain security for global deployment.

Selecting the Right 3.5mm Screw Terminal Block for Your Environment

Application environment determines mechanical endurance and plating requirements.

| Environment | Engineering Challenge | Recommended Solution |

|---|---|---|

| Compact Control Boards | Space limitation | Vertical type, short body design |

| Vibration-Prone Equipment | Screw loosening | Locking washer + higher torque screw |

| High-Temperature Zones | Material deformation | Nickel-plated contacts, PA66 resin |

| Outdoor / Humid Systems | Corrosion and leakage | Anti-oxidation coating, sealed housing |

| OEM Brand Integration | Consistency across series | Color-coded housings + embossed logo |

By evaluating torque data, plating thickness, and certification files, engineers can ensure each OEM configuration achieves the balance between cost and reliability.

Engineering Evolution: Miniaturization Meets Manufacturing Intelligence

The 3.5mm screw terminal block exemplifies how miniaturized design and digital manufacturing intersect.

Chinese OEM manufacturers are increasingly integrating optical inspection (AOI), automated torque analytics, and AI-driven plating control into production.

These technologies eliminate micro-defects, improve assembly repeatability, and enhance predictive maintenance for manufacturing lines—transforming terminal block production into a data-certified precision process.

Redefining OEM Reliability in Compact Electrical Design

The success of the 3.5mm screw terminal block OEM production lies in precise design execution, compliance, and the flexibility to adapt to customer requirements.

This small connector demonstrates how engineering discipline and process control can define large-scale reliability in modern automation systems.

Zhongbo continues to deliver OEM-grade terminal blocks with verified insulation performance, automated assembly precision, and full customization capabilities—empowering global manufacturers to design compact, safe, and efficient electrical systems.

For detailed OEM cooperation or specification support, visit our homepage or contact us.