High-Voltage Stability in Solar Systems: Engineering the 1000V DC Terminal Block

As solar energy adoption accelerates, the performance and safety of 1000V DC circuits have become a defining factor for photovoltaic (PV) efficiency.

The solar terminal block 1000V DC serves as the fundamental connection unit within combiner boxes, string inverters, and DC distribution boards—where every milliamp of current and every volt of insulation matter.

In high-voltage DC environments, precision engineering in connection technology is not optional; it’s what separates a reliable solar installation from a potential hazard.

Understanding the Role of 1000V DC Terminal Blocks in PV Systems

Solar arrays operate under continuous exposure to UV radiation, temperature cycling, and high DC voltage stress.

Terminal blocks in this context perform three critical roles:

-

Secure current transmission between PV modules, fuses, and breakers

-

Insulation and creepage protection to prevent arcing or leakage under high voltage

-

Ease of maintenance for periodic system inspections and replacements

Properly engineered 1000V DC terminal blocks maintain stable contact resistance and thermal performance across years of daily load cycles.

Design and Electrical Principles for 1000V DC Connections

Unlike AC circuits, DC power lacks a zero-crossing point—making arc suppression and contact stability much more difficult.

To counter this, terminal block design integrates specialized mechanical and electrical reinforcements:

| Design Element | Engineering Purpose | Specification Range |

|---|---|---|

| Creepage Distance | Prevents surface discharge | ≥12.5 mm at 1000V DC |

| Contact Material | Maintains low resistance | Nickel-plated copper alloy |

| Housing Material | Flame-retardant and UV-resistant | PA66 UL94 V-0, anti-aging |

| Rated Current | Supports solar string output | 32A–60A continuous load |

| Torque Strength | Ensures stable mechanical binding | 0.5–1.2 Nm for M3–M4 screws |

These specifications align with IEC 60947-7-1 and UL1059 standards for high-voltage industrial components.

General DC Blocks vs. Solar-Rated 1000V Models

| Parameter | General DC Terminal Block | Solar 1000V DC Terminal Block |

|---|---|---|

| Voltage Tolerance | 300–600V DC | Up to 1000V DC continuous |

| Material Resistance | Basic PA | UV-stabilized and anti-aging polymers |

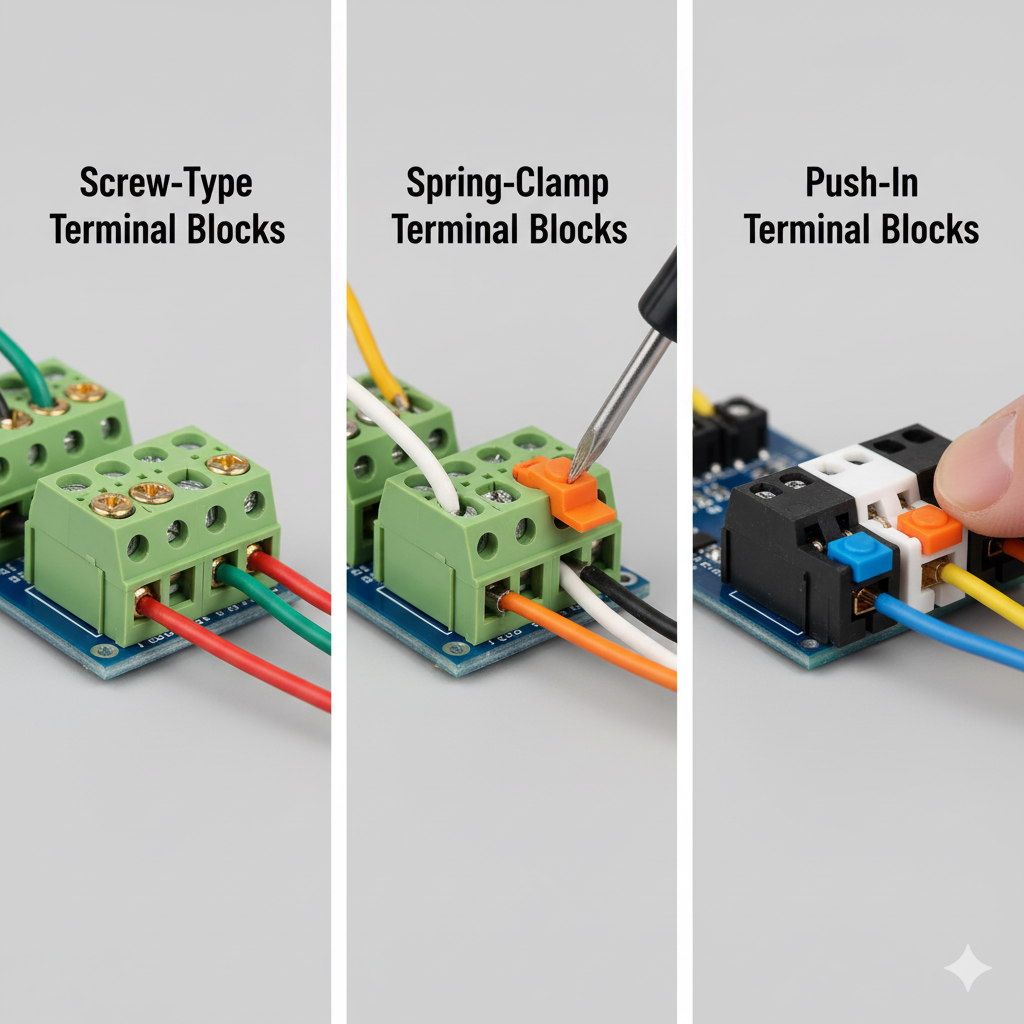

| Connection Type | Standard screw clamp | Reinforced screw or spring cage |

| Temperature Range | -10°C ~ 70°C | -40°C ~ 125°C |

| Environmental Rating | Indoor use | IP20–IP65 (depending on enclosure) |

Solar-rated versions combine mechanical endurance with environmental resistance, essential for rooftop and utility-scale installations.

Thermal Management and Contact Stability Under Load

Long-term exposure to sunlight and ambient heat can degrade materials and loosen conductors.

To prevent these issues, 1000V DC terminal blocks use:

-

High-temperature polyamide housings resistant to deformation

-

Multi-point contact geometry that distributes current evenly

-

Anti-vibration screws maintaining torque over time

-

Brass or tinned-copper conductors for improved oxidation resistance

Finite Element Analysis (FEA) simulations in modern factories help validate temperature rise and stress patterns before production—ensuring safety margins even at 1.2× rated current.

Applications in Photovoltaic and Energy Storage Systems

| System Type | Function of Terminal Block | Design Focus |

|---|---|---|

| PV Combiner Box | Parallel string connection | High current density, compact layout |

| String Inverter Input | Power input and grounding | Thermal endurance |

| Battery Storage System | DC bus connection | Vibration resistance |

| Junction Box | Signal and power separation | Compact insulation housing |

| Hybrid Inverter | Multi-input integration | Pluggable terminal compatibility |

In each case, the 1000V DC block acts as both mechanical anchor and electrical safeguard, ensuring long-term reliability under outdoor stress.

Engineering Guidelines for System Integrators

To ensure stability and compliance in solar installations:

-

Select terminal blocks rated at least 1.25× system voltage for safety margin.

-

Verify materials are UV-resistant and halogen-free for long-term outdoor use.

-

Maintain sufficient air gap between positive and negative conductors (>15mm).

-

Use spring-cage types for frequent thermal cycling environments.

-

Confirm all components pass IEC 61238-1 thermal test and UL1059 dielectric test.

These steps help reduce maintenance costs and prevent early system degradation.

Frequently Addressed Technical Questions

Q1: Why is 1000V DC the standard in solar wiring?

A: It balances efficiency and component availability—allowing long string connections while keeping inverter voltage manageable.

Q2: How do solar terminal blocks prevent arc faults?

A: By using wide creepage distances, heat-resistant materials, and spring-contact mechanisms maintaining consistent pressure.

Q3: Can these blocks be used in ESS battery cabinets?

A: Yes, provided they meet both DC current and temperature endurance specifications.

Q4: What certifications are essential?

A: UL1059, IEC 60947-7-1, and RoHS/REACH compliance are required for export and industrial approval.

Sustaining Solar Reliability Through Precision Connectivity

In high-voltage DC environments, precision engineering is the core of system stability.

The solar terminal block 1000V DC is more than a connector—it’s an integral safeguard that preserves efficiency, mitigates arc risk, and simplifies future maintenance.

Zhongbo continues to design and supply high-voltage terminal solutions for global photovoltaic and energy storage applications, integrating certified materials, automated assembly, and OEM customization.

For engineering collaboration or detailed specifications, visit our homepage or contact us.