Optimizing Industrial Wiring Supply: A Practical Approach to Bulk Terminal Block Purchasing

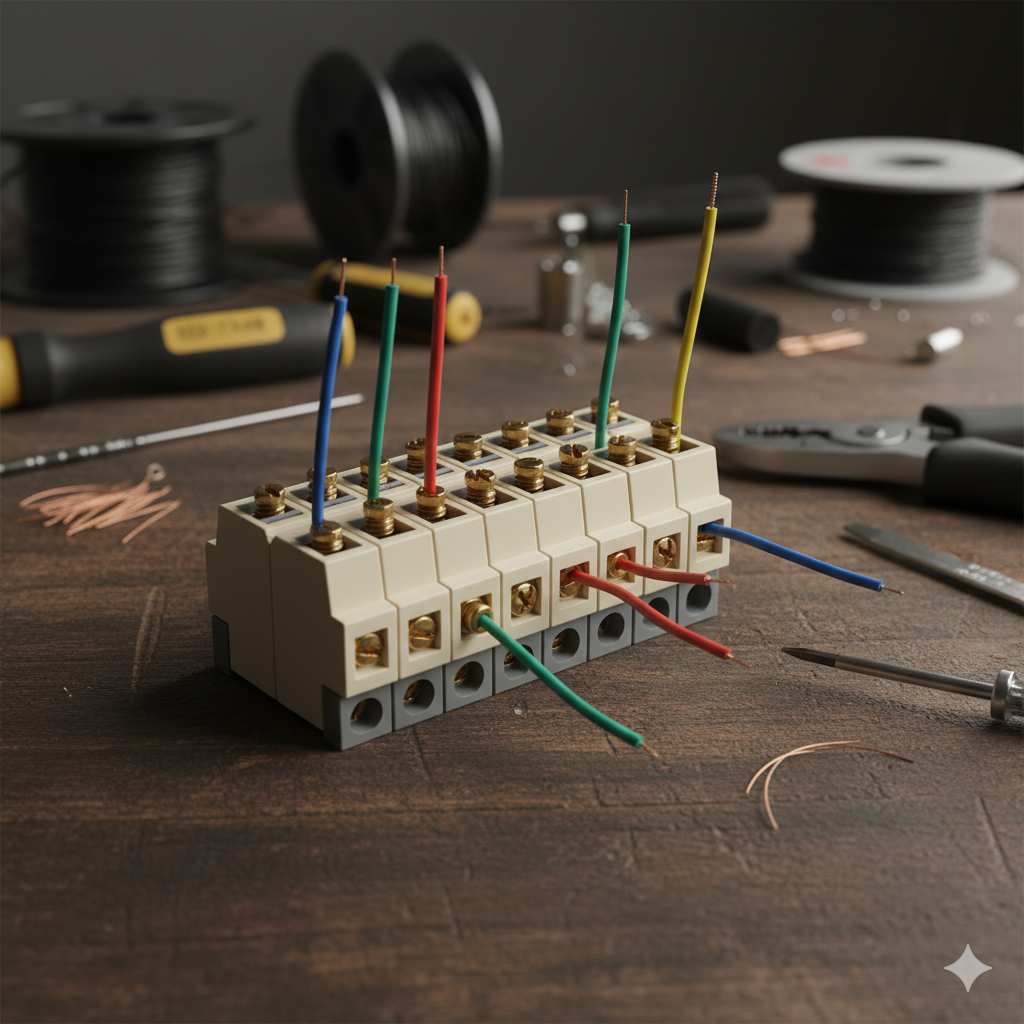

Industrial wiring systems depend on one quiet but essential component — the terminal block. When thousands of units are installed across control panels, automation lines, or energy systems, consistency matters more than anything. That’s why bulk terminal block purchasing isn’t just a procurement activity; it’s a strategic engineering process that defines system reliability for years.

Today, global manufacturers face a dual challenge: lowering unit cost without compromising on safety or durability. The solution lies in merging engineering precision with procurement intelligence — a balance that only a structured bulk purchasing approach can achieve.

Understanding the Industrial Wiring Supply Challenge

In large-scale wiring projects, every connection is a potential failure point.

A single unstable contact or inconsistent housing tolerance can trigger overheating, system downtime, or costly rework.

Traditional purchasing often focuses on cost per unit, but industrial wiring supply optimization means viewing the terminal block as part of a system — not a spare part.

Challenges commonly faced by bulk buyers include:

-

Multiple suppliers with inconsistent specifications.

-

Long lead times and uneven quality across shipments.

-

Certification mismatches for export to different markets (UL, CE, or RoHS).

-

Packaging and labeling errors that disrupt assembly lines.

In short, optimizing supply means aligning every technical detail — from conductor plating to carton stacking — under one repeatable standard.

The Engineering Principles Behind Reliable Bulk Procurement

Bulk purchasing of terminal blocks must follow measurable technical parameters rather than subjective supplier claims.

-

Material Integrity — Use PA66 or PBT housings rated UL94 V-0 to withstand high temperature and resist flame propagation.

-

Conductor Performance — Choose brass or copper alloy terminals with anti-corrosion plating (tin or nickel).

-

Torque and Contact Retention — Every batch should be torque-tested and heat-cycled to detect micro-cracks or plating wear.

-

Dimensional Consistency — Tight tolerances (±0.1 mm) ensure compatibility with PCBs and DIN rails during high-speed assembly.

-

Testing & Traceability — Factory test data and batch codes help track product lineage for audits or warranty claims.

When scaled to thousands of pieces, these details determine not only the system’s lifespan but also the supplier’s credibility.

Comparing Bulk Purchasing Models: Local vs. Global Sourcing

| Criteria | Local Procurement | Global Sourcing (e.g. China) |

|---|---|---|

| Unit Cost | Higher due to limited scale | 15–35% lower through economies of scale |

| Lead Time | Shorter domestically | Longer shipping, but stable schedule |

| Certification Coverage | Regional standards | UL, CE, and RoHS compliant for export |

| Customization | Limited | Fully OEM configurable (pitch, color, branding) |

| Logistics | Flexible small lots | Ideal for containerized bulk orders |

For many OEMs, the optimal strategy is hybrid: sourcing high-volume, standardized blocks from global factories while maintaining small-batch flexibility locally.

Core Advantages of Structured Bulk Terminal Block Purchasing

A technical purchasing plan transforms what was once a transactional process into a supply optimization system:

-

Quality Stability Across Batches

Automated assembly and inline testing ensure identical torque, color, and marking between shipments. -

Reduced Cost of Ownership

Bulk volume discounts combined with consistent quality reduce installation rework and warranty costs. -

Scalable Logistics

Factories near major ports (e.g., Ningbo or Shanghai) offer container consolidation and just-in-time shipping for long-term projects. -

Simplified Engineering Validation

Using the same certified series across projects streamlines product validation and documentation for export.

In essence, structured purchasing replaces uncertainty with measurable control — the foundation of efficient industrial wiring systems.

Real-World Applications and Procurement Scenarios

Bulk terminal block purchasing benefits every sector where wiring density and repeatability matter:

-

Automation Control Panels — Repetitive terminal layouts benefit from uniform connectors and pre-marked numbering.

-

Renewable Energy Systems — Solar or wind systems require high-voltage DC blocks rated up to 1000 V.

-

Building and HVAC Projects — Consistent screw or spring-clamp terminals simplify field installation.

-

Electrical Distribution Cabinets — Large enclosures gain from modular and stackable designs for faster panel wiring.

In each case, sourcing in bulk not only reduces cost per unit but guarantees mechanical compatibility and stable current flow.

Selection Guidance for Engineering-Driven Buyers

Before placing a bulk order, engineers should evaluate more than MOQ and price.

-

Verify certification scope — UL1059 for North America, IEC60947-7-1 for Europe, GB for China.

-

Match wire range and torque rating to the actual conductor type.

-

Confirm operating temperature range (-40 °C – 125 °C) to fit industrial environments.

-

Request CAD drawings and datasheets to ensure mechanical fit before mass assembly.

-

Insist on lot-traceable documentation — real data builds real reliability.

This checklist transforms procurement into an engineering-led quality gate.

Frequently Asked Questions

Q1: How do I estimate bulk order quantity for terminal blocks?

A: Calculate total connection points per project, then add 10–15 % for maintenance stock and system revisions.

Q2: Is OEM branding available for bulk terminal blocks?

A: Yes. Many certified suppliers support logo printing, customized pitch, and packaging for private labels.

Q3: How can I balance shipping cost and lead time?

A: Combine multiple models in one container and align production with project timelines to minimize warehousing.

Q4: What testing should be performed before shipment?

A: Torque, insulation resistance, high-pot testing, and dimensional inspection are mandatory for every batch.

Elevating Industrial Wiring Through Smarter Procurement

Efficient industrial wiring isn’t built on luck — it’s designed through disciplined sourcing.

By integrating certification, traceability, and cost-optimized logistics, bulk terminal block purchasing becomes a strategic engineering function rather than a simple buying task.

Zhongbo continues to support global wiring manufacturers with certified terminal blocks, scalable OEM options, and port-adjacent export logistics that ensure reliability from production to installation.

For detailed quotations or custom project solutions, visit our homepage or contact us.