Connecting Scale and Precision: The Role of a Terminal Block Wholesale Distributor in Modern Supply Chains

Market Pain Points: The Cost of Fragmented Sourcing

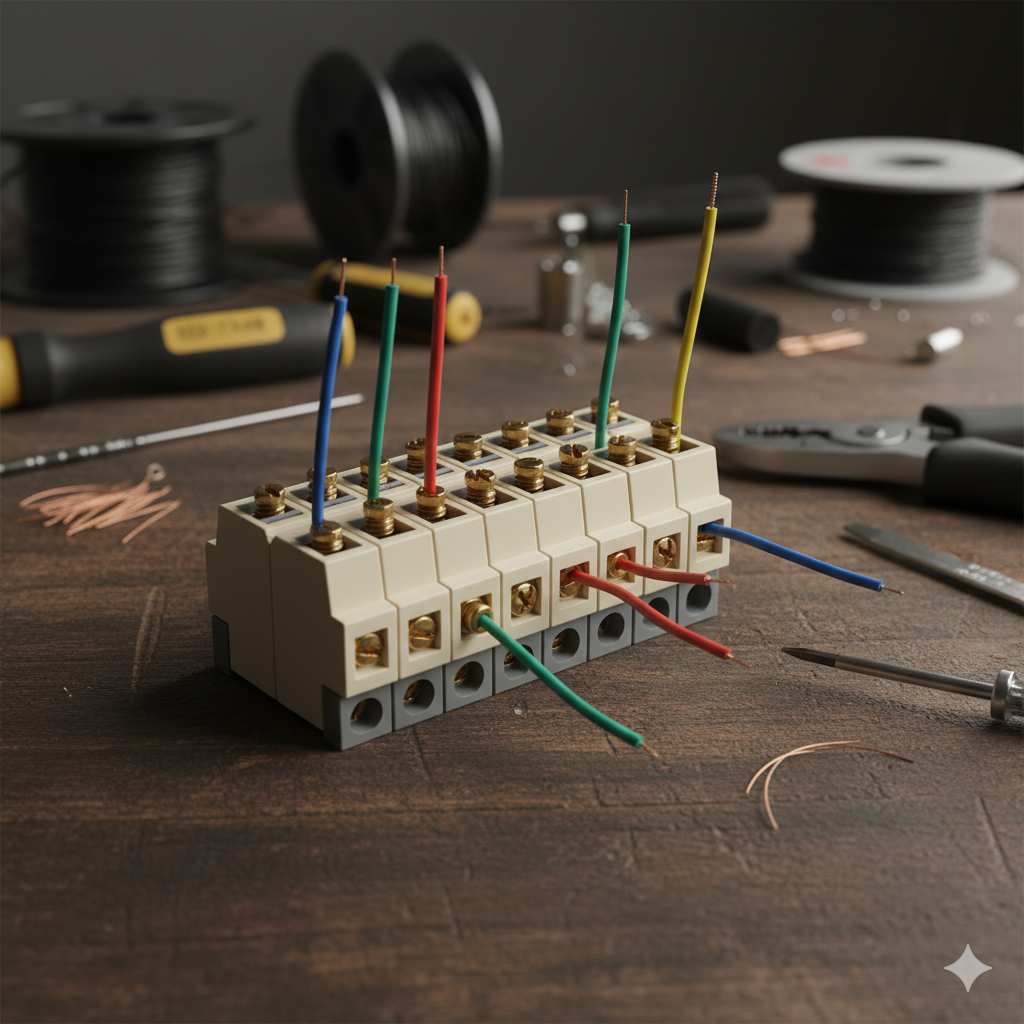

For manufacturers, integrators, and control-panel builders, wiring hardware is a small component with a large impact.

Yet sourcing terminal blocks across multiple suppliers often leads to inconsistent specifications, uncertain certifications, and mismatched deliveries.

A panel built with mixed brands may look functional but fail UL or CE audits because the dielectric ratings, torque values, or flame-retardant materials differ.

Even worse—short shipments, irregular lead times, and regional compliance issues can halt entire production lines.

In a globalized supply chain, what buyers need is consistency at scale—and that’s exactly where a professional terminal block wholesale distributor becomes indispensable.

The Principle: Distribution as a Technical Extension, Not Just Logistics

Modern electrical distribution isn’t about reselling—it’s about engineering translation.

A qualified distributor bridges the gap between manufacturers, certification standards, and end users.

At its core, a wholesale distributor’s role includes:

-

Specification Matching — Mapping terminal block models across multiple brands to equivalent technical standards (UL1059, IEC60947-7-1).

-

Batch Consistency — Ensuring all units in bulk supply maintain identical torque and insulation characteristics.

-

Certification Assurance — Verifying that products meet UL, CE, CCC, or CSA depending on market destination.

-

Inventory Forecasting — Predicting customer demand cycles and reserving stock before seasonal production peaks.

In other words, a true technical distributor acts less like a reseller and more like a supply chain integrator for precision components.

Standard Procurement vs. Wholesale Distribution

| Aspect | Standard Purchase | Wholesale Distributor Model |

|---|---|---|

| Sourcing | Multiple small suppliers | Single-channel bulk procurement |

| Product Range | Limited | Cross-brand equivalency |

| Certification | Varies | Verified, market-ready |

| Logistics | Buyer-managed | Centralized, predictable |

| Support | Basic | Technical + compliance support |

| Cost Efficiency | Lower at first glance | Superior in lifetime cost and downtime reduction |

While buying directly from multiple factories seems cheaper, hidden costs—testing, verification, downtime—quickly offset the savings.

Working with a specialized distributor simplifies procurement, reduces risk, and creates a measurable advantage for long-term operations.

The Solution: Centralized Engineering Distribution

A professional terminal block wholesale distributor builds its strength on three pillars—standardization, traceability, and scalability.

-

Standardization

They consolidate multiple manufacturers under unified categories—screw, spring, or pluggable terminal blocks—making substitutions seamless. -

Traceability

Each batch is recorded with material and torque test certificates, ensuring compliance across regional regulations. -

Scalability

Through partnerships with OEM factories, distributors can flex between small pilot quantities and full-container shipments, maintaining consistent quality across orders.

This model allows global buyers to access both cost efficiency and engineering reliability—the two hardest goals to achieve simultaneously.

Advantages of Working with a Wholesale Distributor

-

Guaranteed Compliance

All batches conform to UL, CE, and RoHS standards, eliminating re-certification risks. -

Faster Delivery, Lower MOQ

Regional warehouses shorten transit time and allow mixed-model bulk orders. -

Unified Technical Support

A single contact point manages cross-brand compatibility and design assistance. -

Transparent Cost Control

Predictable pricing across large volumes, including logistics and duty management. -

Inventory Assurance

Distributors hold buffer stock for recurring clients—vital for industries with continuous production.

Reliability isn’t built in a factory—it’s built across a network.

That’s why distributors matter as much as the manufacturers themselves.

Application Scenarios

-

Automation Equipment OEMs — Require multiple terminal types with identical certification for global deployment.

-

Renewable Energy Installations — Need large-scale supply of 1000V DC-rated terminal blocks for solar systems.

-

Industrial Controls — Demand pre-labeled, color-coded terminal blocks for high-density control cabinets.

-

Building Management Systems — Require consistent delivery schedules and flexible configuration support.

-

Export Distributors & Assemblers — Depend on uniform compliance documentation to meet foreign import standards.

Selection Guide: How to Choose the Right Distributor

| Evaluation Factor | Why It Matters | What to Look For |

|---|---|---|

| Certification System | Ensures export legality | UL/CE/CCC verified batches |

| Technical Capability | Avoids wiring mismatch | Engineering-trained support staff |

| Inventory Depth | Prevents delivery gaps | Multi-brand stocking |

| Price Transparency | Reduces budgeting risk | Fixed pricing with volume tiers |

| After-Sales Service | Simplifies warranty | Replacement and re-certification support |

When selecting a supplier, verify that they operate not as intermediaries, but as authorized channel partners of terminal block manufacturers.

Frequently Asked Questions

Q1: Do wholesale distributors handle OEM customization?

Yes. Most leading distributors collaborate with OEM factories for logo printing, packaging, or structural customization.

Q2: What’s the MOQ for wholesale orders?

Typically between 500 and 2,000 units per model, depending on material and certification type.

Q3: Can distributors supply mixed models in one shipment?

Yes. Multi-model consolidated shipping is one of the core advantages of working through a distributor network.

Q4: How are counterfeit or mixed-brand risks avoided?

Reputable distributors use serialization and test documentation from verified OEM partners.

Strengthening Global Supply Chains Through Partnership

In an age of fragmented supply, terminal block wholesale distributors provide stability—combining engineering knowledge, stock availability, and compliance discipline.

They allow manufacturers to scale globally without the chaos of multi-source risk.

If you’re seeking a reliable sourcing partner for certified electrical connection components, visit our homepage or contact us via Contact Us.

Zhongbo integrates OEM-grade production and wholesale distribution strength to deliver precision, safety, and trust in every connection.