How Asia’s OEM Terminal Block Factories Power Global Manufacturing

Across today’s global industrial landscape, Asia stands at the center of electrical connectivity manufacturing.

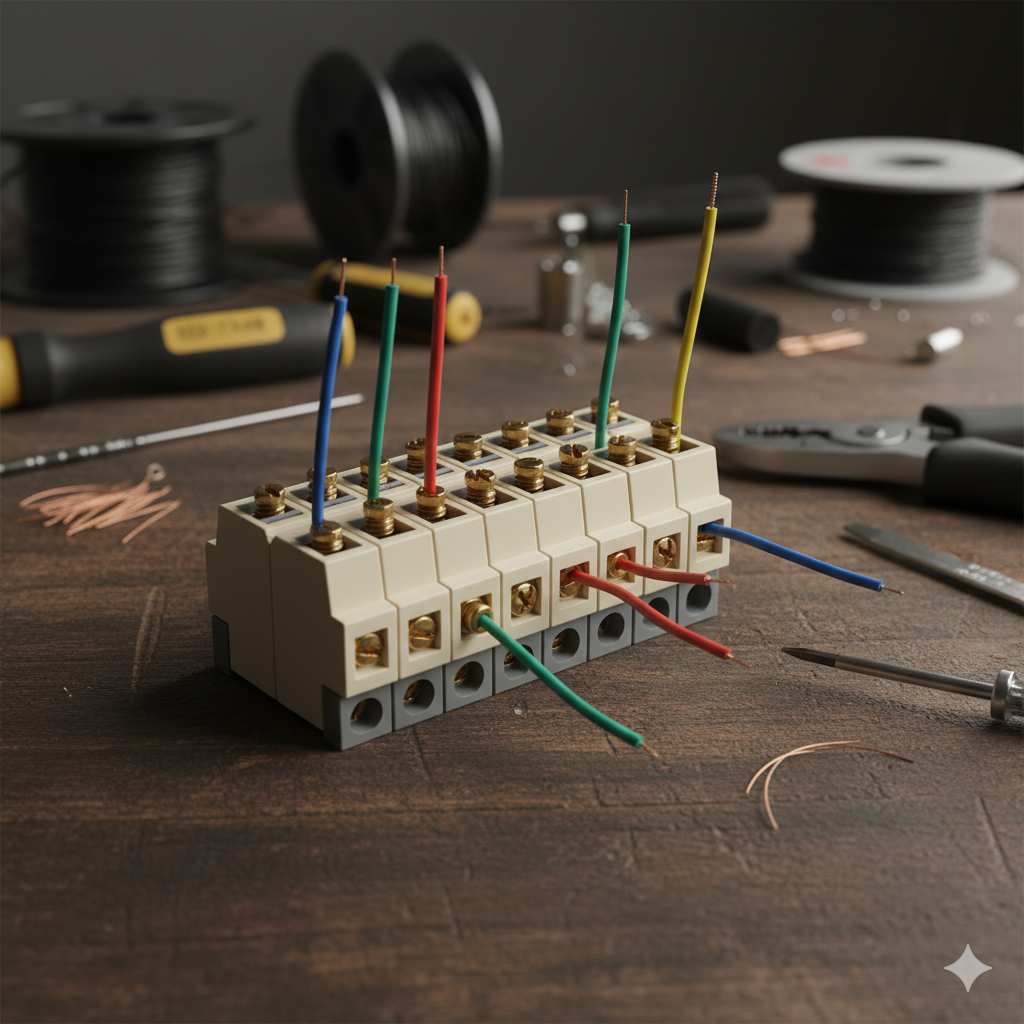

From control panels in Germany to energy grids in Africa, terminal blocks designed and produced by Asian OEM factories form the hidden infrastructure that powers automation, safety, and reliable communication between systems.

For OEM customers worldwide, partnering with an Asia terminal block OEM factory offers not just cost efficiency — but precision, certification, and engineering support across diverse industries.

The Rise of Asia’s OEM Terminal Block Industry

Over the past 20 years, Asia has evolved from a regional supplier base into a global OEM powerhouse.

Countries like China, South Korea, Japan, and Taiwan now operate thousands of factories specializing in industrial connectors, control wiring terminals, and power distribution systems.

This rise is driven by three forces:

-

Advanced Manufacturing Technology – CNC injection molding, automatic stamping, and robotic assembly enable consistent quality and mass customization.

-

Comprehensive Certification – Factories align with UL, CE, TUV, and ISO9001 standards, ensuring global compliance.

-

Integrated Supply Chains – Asia’s component ecosystems minimize lead times and simplify sourcing for international OEM partners.

Together, these strengths make Asia the most dependable region for large-scale, certified, and cost-efficient terminal block production.

Engineering Foundations of OEM Terminal Block Production

Modern OEM factories in Asia operate with precision-driven standards to ensure global export compatibility.

| Engineering Parameter | Specification | Industry Impact |

|---|---|---|

| Housing Material | PA66 / PBT UL94 V-0 | Fire-retardant, stable at high temp |

| Conductor | Tin-plated brass or copper | Corrosion-resistant conductivity |

| Torque Range | 0.4–1.5 Nm | Reliable wire retention |

| Voltage / Current Rating | 300V–1000V / up to 150A | Suitable for automation & power grids |

| Testing Standards | IEC60947, UL1059, EN60998 | Ensures international safety compliance |

Factories also apply automatic torque monitoring, 3D inspection, and environmental stress testing, guaranteeing consistency across millions of units shipped globally each year.

OEM Advantages: Why Global Brands Choose Asia

| Advantage | Description | Value for Buyers |

|---|---|---|

| Custom Design Flexibility | Adaptable molds, materials, and labeling | Supports brand differentiation |

| Scalable Production | From prototypes to mass orders | Shortens time-to-market |

| Global Certification | UL / CE / TUV ready | Smooth customs and safety clearance |

| Integrated Tooling | In-house mold & tooling | Reduces external dependency |

| Competitive Pricing | Efficient labor + logistics | Lower total project cost |

This OEM model allows international clients to maintain brand control and technical quality without the burden of owning production infrastructure — a key competitive edge in fast-moving industries.

Industry Applications of Asian Terminal Block OEMs

Asia’s terminal block factories supply a wide spectrum of applications requiring reliable wiring and durable materials:

-

Automation & robotics systems – for PLC wiring, signal distribution, and relay modules

-

Energy and solar systems – 1000V DC blocks for PV and ESS inverters

-

HVAC and building control – modular terminals for temperature and power management

-

Transportation and EVs – compact high-current connectors for onboard modules

-

Consumer and lighting electronics – miniature pluggable and PCB terminal blocks

By maintaining flexible OEM design capabilities, factories in Asia serve diverse sectors while maintaining standardized compliance for cross-market use.

Selecting the Right OEM Partner in Asia

Choosing the ideal OEM factory goes beyond finding the lowest cost — it’s about aligning technical expertise with business strategy.

Before finalizing a supplier, global buyers should evaluate:

-

Certification Scope — Verify UL, CE, or TUV documentation for each product line.

-

Design Capability — Ensure in-house R&D for mold modification and 3D prototyping.

-

Quality Traceability — Review inspection reports and torque test procedures.

-

Material Origin — Prefer UL-listed resin suppliers and lead-free metal sources.

-

Global Export Experience — Look for proven partners with EU/US customs familiarity.

Partnering with a technically mature factory ensures both engineering reliability and regulatory compliance — key factors in sustaining long-term brand reputation.

Frequently Asked Questions

Q1: Can Asian OEM factories produce custom-branded terminal blocks?

A: Yes. Most OEM partners provide logo printing, custom housing colors, and packaging solutions.

Q2: What certifications are common among export-oriented factories?

A: UL, CE, TUV, and ISO9001 certifications are standard for global market readiness.

Q3: Are MOQ requirements flexible for new OEM projects?

A: Yes. Many factories support small-batch pilot runs before scaling up to full production.

Q4: How do Asian OEM factories ensure consistent quality across orders?

A: Automated torque and insulation testing are applied throughout the production cycle.

Driving Global Connectivity Through Asian Engineering

The global demand for safe, modular wiring solutions continues to expand — and Asia’s OEM factories are meeting it with unmatched scale and reliability.

With certified materials, flexible customization, and efficient production systems, Zhongbo and other leading Asian manufacturers continue to power the world’s automation and energy sectors.

For partnership inquiries or OEM customization requests, visit our homepage or contact us.