Engineering Efficiency at Scale: Understanding DG301 Terminal Block Wholesale Manufacturing

In industrial automation and power distribution, reliability begins with the smallest link—the terminal block. The DG301 terminal block series has become a trusted component for manufacturers seeking compact design, stable current transmission, and easy PCB integration.

This article dives into how large-scale DG301 terminal block wholesale manufacturing combines material engineering, mechanical precision, and regulatory compliance to meet global electrical standards.

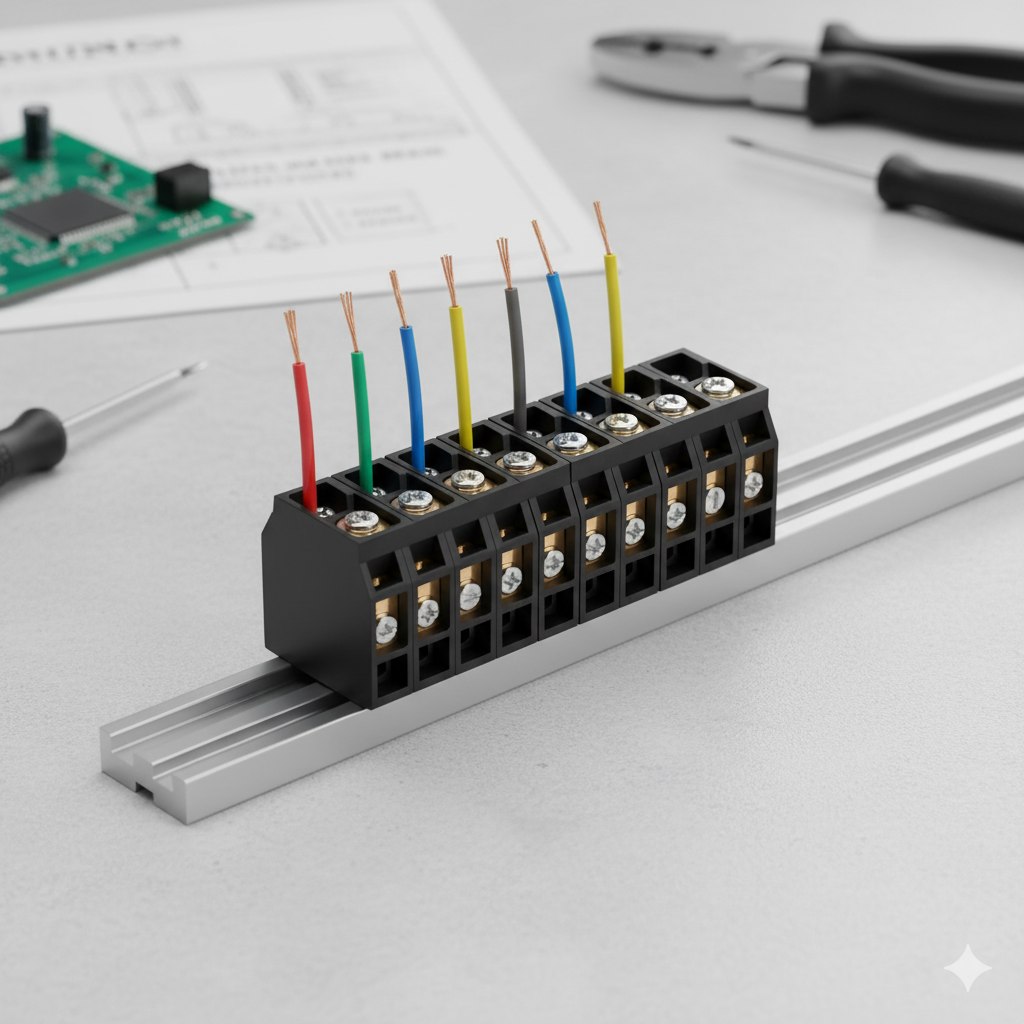

The Structural Logic of DG301 Terminal Blocks

The DG301 terminal block features a 3.81mm to 5.08mm pitch pluggable design, optimized for modular wiring in control panels and circuit boards. Its structure offers a balance between compactness and current-carrying capacity, supporting up to 15A per pole.

Key engineering attributes include:

-

Pluggable header and socket system for quick assembly and maintenance.

-

Double-layer insulation design ensuring dielectric protection between terminals.

-

Guide grooves and screw locks to secure stability under vibration.

-

Polarization features that prevent mismatched insertion.

This combination of safety and functionality enables engineers to design denser, more reliable PCBs without sacrificing electrical integrity.

Precision Materials and Electrical Integrity

Performance in DG301 terminal blocks depends heavily on material consistency and processing accuracy.

| Component | Material | Engineering Purpose |

|---|---|---|

| Housing | PA66 UL94 V-0 | Flame retardant, thermal resistance |

| Terminals | Brass (tin/nickel plated) | Corrosion resistance and conductivity |

| Screws | Carbon or stainless steel | Secure torque and mechanical strength |

| Plug Body | Glass-fiber reinforced resin | Dimensional accuracy and durability |

Advanced molding and controlled plating thickness ensure low contact resistance (<10 mΩ) and stable dielectric strength across operating cycles. The result: every connector performs uniformly, even under repeated plug-in operations or environmental stress.

High-Volume Manufacturing and Process Control

A DG301 terminal block factory integrates automated injection molding, CNC machining, and endurance testing into its production workflow.

-

Molded insulation housings are produced with ±0.02mm tolerance to guarantee consistent plug fit.

-

Contacts are stamped and plated using robotic precision for uniform conductivity.

-

Screw-torque assembly lines ensure accurate clamping across all poles.

-

Continuity and dielectric testing confirm full electrical reliability before packing.

Such high-volume control minimizes variation across batches, ensuring each connector conforms to UL and IEC electrical standards—critical for wholesale-level distribution.

Compliance and Global Standards

DG301 terminal block wholesale suppliers adhere to multiple international frameworks that define connector safety and performance:

-

UL1059: Governs flammability, torque, and insulation strength.

-

IEC60947-7-1: Ensures reliable low-voltage connection for switchgear applications.

-

RoHS & REACH: Confirms eco-friendly material compliance.

-

CE Certification: Enables global trade and system integration.

Factories that internalize these test protocols can streamline documentation and quality verification for OEM or distributor clients worldwide.

Comparative Engineering: DG301 vs. Other Terminal Block Families

| Feature | DG301 | DG500 | DG508 |

|---|---|---|---|

| Pitch | 3.81–5.08mm | 5.0mm | 5.08mm |

| Rated Current | Up to 15A | Up to 24A | Up to 20A |

| Mounting | PCB screw-plug | PCB + cable clamp | Modular pluggable |

| Vibration Resistance | High | Very High | Medium |

| Primary Use | Compact automation, instrumentation | Power systems | General control panels |

DG301 stands out for space efficiency and modular assembly, making it particularly suitable for compact control electronics, lighting controllers, and PLC terminals.

Selection and Application Guidance Across Industrial Scenarios

Choosing the right DG301 configuration involves understanding environmental constraints and electrical load demands.

| Application | Technical Priority | Engineering Recommendation |

|---|---|---|

| Compact Control Panels | Limited space, frequent rewiring | 3.81mm pitch, vertical header type |

| Power Interface Boards | Higher load capacity | 5.08mm pitch, nickel-plated contacts |

| Industrial Machinery | Vibration, dust, temperature | PA66 housing with anti-vibration screws |

| Lighting and HVAC Systems | Ease of installation | Horizontal entry type with captive screws |

| OEM and Custom Devices | Branding, scalability | OEM-engraved blocks with custom color housing |

For engineers, attention should focus on contact material, plating thickness, and clearance distances, all of which determine current stability under continuous operation.

Procurement teams benefit from choosing suppliers with in-house testing, UL certification, and custom mold design capability to ensure OEM consistency.

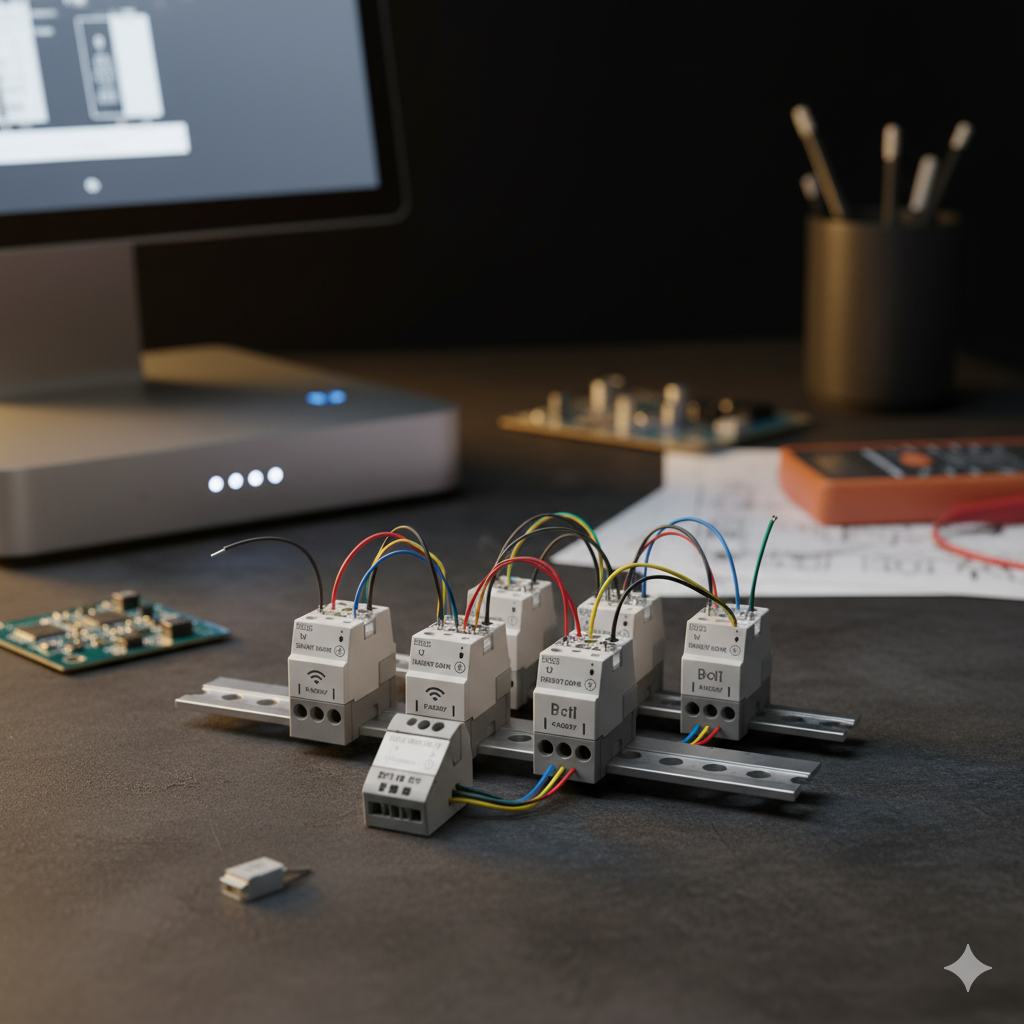

Integrating DG301 into Next-Generation Industrial Design

The DG301 terminal block represents the industry’s ongoing shift toward compact, high-performance modular interconnects. As industrial automation evolves, the ability to combine dense wiring layouts with mechanical reliability becomes a design priority.

Leading manufacturers are adopting automated visual inspection systems, halogen-free materials, and AI-driven process calibration to eliminate tolerance drift and improve connector lifespan. This integration of precision molding and digital quality control is redefining what wholesale reliability means in electrical engineering.

Sustaining Global Connectivity Through Manufacturing Excellence

The global success of the DG301 terminal block lies in its repeatable precision and adaptability across electrical ecosystems. Each unit manufactured embodies the principles of engineering discipline, process control, and international compliance.

Zhongbo continues to refine DG301 wholesale production through automated assembly, strict material validation, and flexible OEM integration—empowering engineers and distributors to build smarter, safer, and globally compatible wiring systems.

For product specifications, OEM inquiries, or technical discussions, please visit our homepage or contact us.