Precision Interfaces in Control Systems: Inside the PCB Terminal Block 5.08mm Pitch Design

In modern automation and industrial electronics, the stability of every circuit depends on precise, repeatable electrical interfaces. The PCB terminal block 5.08mm pitch has become an industry standard because it balances mechanical integrity, electrical conductivity, and compact modular design.

This article reveals how the engineering of 5.08mm pitch terminal blocks ensures long-term system reliability—bridging design theory, production control, and real-world application.

The Engineering Logic Behind the 5.08mm Pitch Standard

The 5.08mm pitch is not arbitrary—it represents a proven balance between electrical clearance, component density, and mechanical torque.

A smaller pitch reduces PCB space consumption, while maintaining adequate creepage distance for 250–300V circuits.

At this dimension, terminal blocks provide:

-

High current capacity (up to 16A) for industrial modules.

-

Consistent torque retention for repeated wiring operations.

-

Optimized insulation that prevents leakage and arcing.

-

Compatibility with automation equipment like PLCs and power supplies.

This standard pitch enables global interoperability across automation systems, lighting control units, and instrumentation boards.

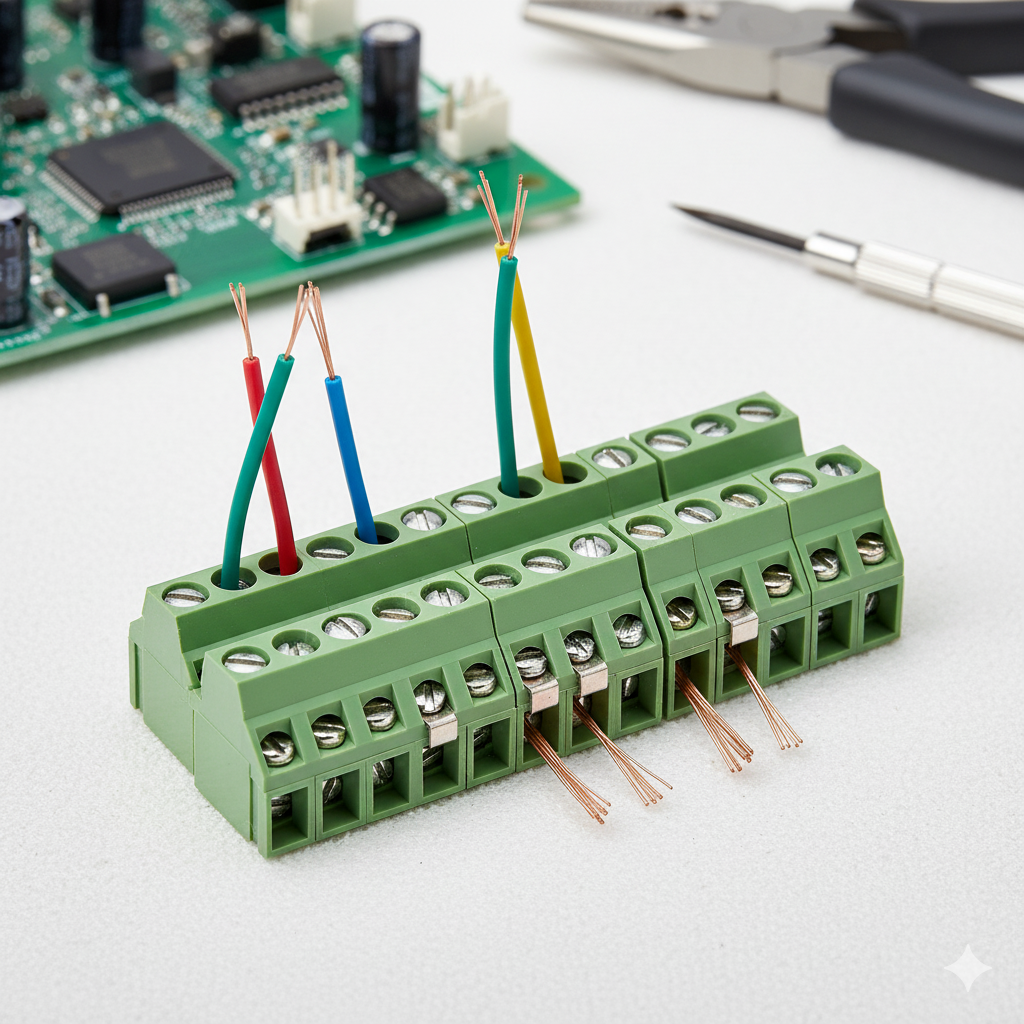

Material Science and Structural Durability

Reliability starts with material consistency. Every 5.08mm terminal block combines high-temperature-resistant polymers with conductive metals engineered for thermal stability.

| Component | Material | Engineering Role |

|---|---|---|

| Housing | PA66 UL94 V-0 | Flame retardancy, dimensional stability |

| Contacts | Brass (tin or nickel plated) | Low contact resistance, corrosion protection |

| Screws | Carbon steel, zinc plated | Torque endurance and reusability |

| Plug Header | Glass fiber reinforced PA | Mechanical rigidity under load |

Factories ensure ±0.02mm tolerance in housing molds, maintaining consistent alignment between terminal interfaces and PCB holes.

Combined with precision plating thickness (2–3μm), this ensures both low resistance and long-term oxidation resistance.

Manufacturing Processes That Define Reliability

Modern PCB terminal block production lines combine mechanical automation with inline testing.

-

High-Pressure Injection Molding: Guarantees wall thickness uniformity for insulation.

-

CNC-Milled Molds: Achieve geometric consistency across multiple cavity tools.

-

Plating Line Control: Uses automated sensors for bath composition and adhesion testing.

-

Torque Validation: Robotic tightening verifies screw performance in real use conditions.

-

Dielectric Testing: Ensures leakage current < 0.5mA at 500V.

Such engineering discipline allows terminal blocks to maintain stable contact resistance (<10 mΩ) even after thousands of plug/unplug cycles.

Compliance and Certification Framework

The reliability of 5.08mm pitch terminal blocks depends on adherence to global safety frameworks.

Top-tier manufacturers integrate compliance testing directly into design validation:

-

UL1059 – Terminal block safety certification for dielectric strength and mechanical integrity.

-

IEC60947-7-1 – Regulates low-voltage connections for switchgear systems.

-

RoHS / REACH – Ensures lead-free and non-toxic materials.

-

ISO9001 – Confirms traceable quality management.

This compliance chain ensures that every terminal block can safely operate in both European and North American electrical panels.

5.08mm vs. Other PCB Terminal Configurations

| Specification | 3.81mm Pitch | 5.08mm Pitch | 7.62mm Pitch |

|---|---|---|---|

| Rated Voltage | 150V | 300V | 600V |

| Rated Current | 8A | 16A | 20A+ |

| Board Density | High | Balanced | Low |

| Wire Range | 0.5–1.5mm² | 0.75–2.5mm² | 1.0–4.0mm² |

| Typical Use | Sensors, compact modules | Automation, control boards | Power supplies, relays |

The 5.08mm pitch acts as the engineering midpoint—compact enough for dense PCB layouts, yet strong enough for industrial-grade current loads.

Application Mapping Across Industrial Environments

PCB terminal blocks with 5.08mm spacing are deployed across sectors that demand stable current flow and frequent maintenance cycles:

-

PLC and Control Modules: Secure signal distribution for automation logic.

-

Power Conversion Systems: Reliable DC/AC interface connections.

-

Industrial Lighting Units: Compact mounting for high-output drivers.

-

Instrumentation Panels: Stable low-noise signal wiring.

-

Renewable Energy Systems: Withstand high temperature and humidity exposure.

Each application benefits from the same precision geometry that allows secure wiring while ensuring dielectric isolation between adjacent terminals.

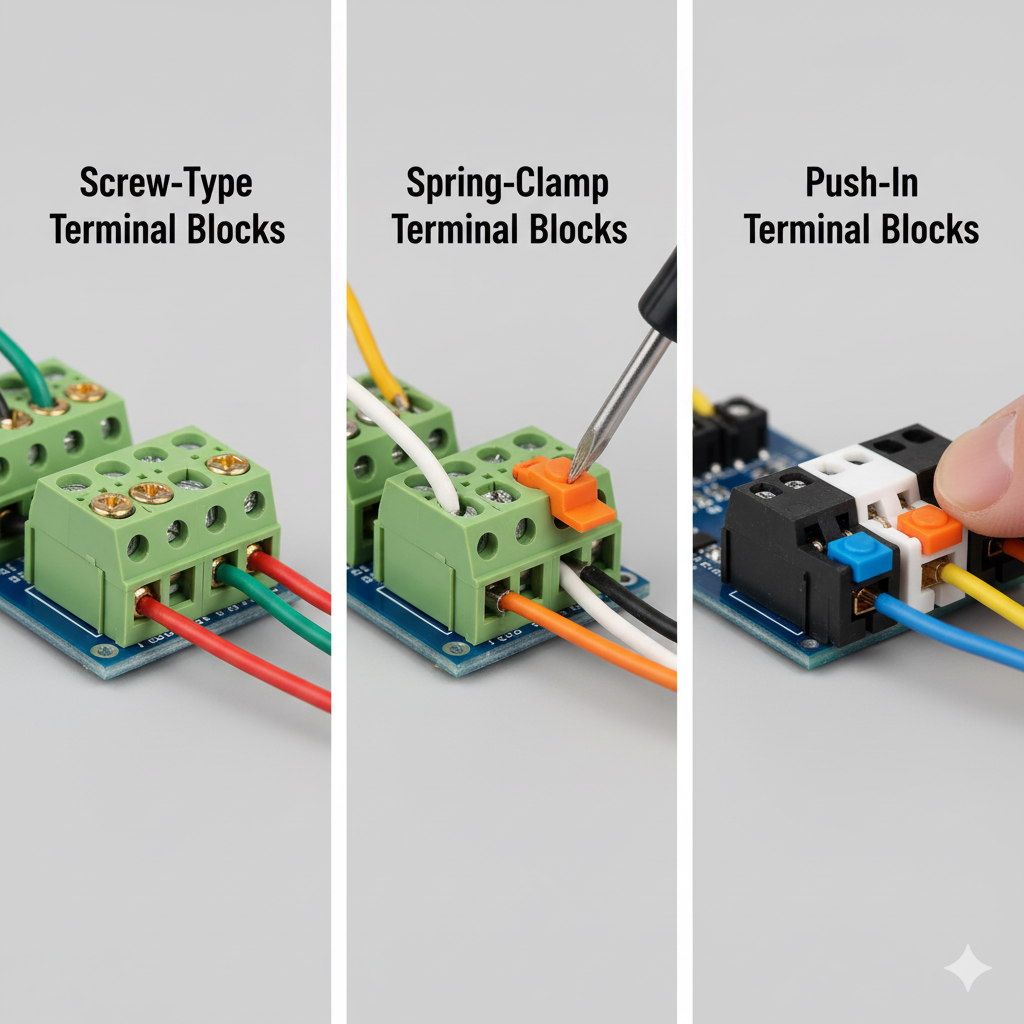

Configuration Selection by Application Condition

Selecting the optimal 5.08mm terminal block depends on both environmental stress and electrical load.

| Environment | Engineering Focus | Recommended Design |

|---|---|---|

| High-Temperature Control Boards | Heat dissipation | Nickel-plated brass contacts, PA66 housing |

| Vibration-Intensive Machinery | Mechanical stability | Screw-lock type with spring washers |

| Compact Automation Panels | Space optimization | Horizontal entry, 5.08mm dual-level block |

| Outdoor or Humid Sites | Corrosion protection | Sealed plug interface, anti-oxidation coating |

| OEM System Integration | Design consistency | Custom pole count and branded mold engraving |

Procurement engineers should evaluate:

-

Contact plating thickness (≥2μm)

-

Clearance distances per voltage rating

-

UL/IEC certification number availability

-

Modular assembly compatibility

Reliable suppliers will provide full electrical test data and dimensional drawings, ensuring compatibility with existing PCB footprints.

Advancing PCB Connectivity Through Manufacturing Intelligence

As automation scales globally, the 5.08mm pitch terminal block evolves beyond a passive component—it becomes a data-driven product.

Manufacturers are integrating AI-based inspection systems, digital torque monitoring, and in-line vision QC to eliminate micro-defects and improve repeatability.

This transformation merges mechanical precision with electronic quality assurance, ensuring that every connector supports not just power, but system-level reliability and safety in connected industries.

Building Global Trust Through Engineering Precision

The continued success of the PCB terminal block 5.08mm pitch lies in its balance between density, current capacity, and structural stability.

Each component reflects decades of refinement in mechanical design and process discipline.

Zhongbo continues to pioneer this evolution by integrating automated production lines, UL-certified materials, and flexible OEM solutions—helping global manufacturers design more compact, safer, and intelligent control systems.

To explore customized configurations or bulk procurement options, visit our homepage or contact us.