Designing for Client Needs: OEM Flexibility in AC Terminal Block Manufacturing

Why Standard Models Fail in Complex Projects

In today’s energy and automation industries, electrical systems face greater complexity and safety requirements than ever before. Standard AC terminal blocks often lack the adaptability for projects where:

-

High current capacity is required in renewable energy farms.

-

Compact layouts are needed inside automation cabinets.

-

Vibration resistance is critical in railway systems.

-

Rapid maintenance is essential in commercial buildings.

These pain points mean that simply choosing off-the-shelf components can increase downtime, installation errors, and compliance risks. According to the International Electrotechnical Commission (IEC), up to 30% of electrical system failures are linked to inadequate connectors (source: IEC). OEM flexibility directly addresses these shortcomings.

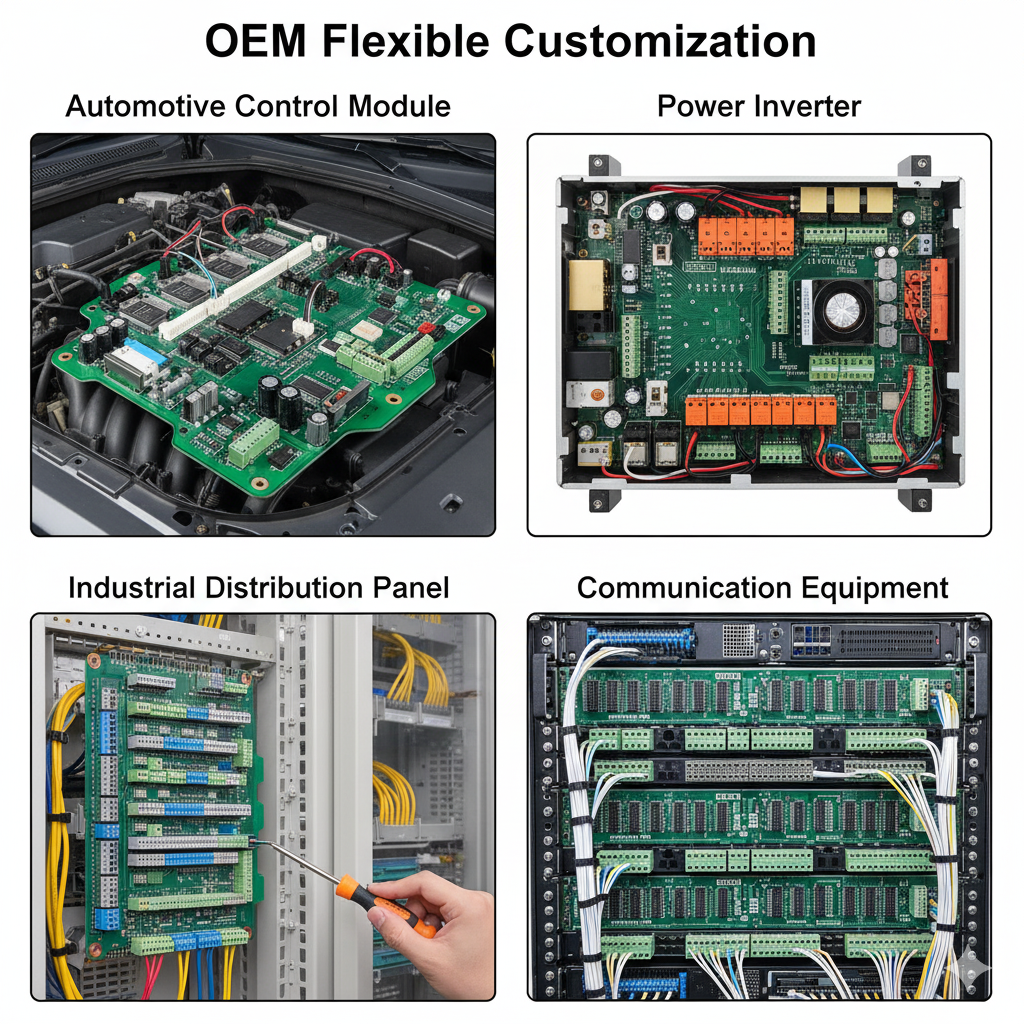

Industry-Specific Needs and Tailored Solutions

Renewable Energy Systems

Solar inverters and wind turbines operate in outdoor, high-temperature environments. Custom AC terminal blocks with flame-retardant housings, reinforced insulation, and corrosion-resistant alloys ensure long-term reliability.

Industrial Automation

Automation panels often have limited cabinet space, making wiring errors common. OEM compact plug-in blocks with modular layouts and color-coded marking enable faster installation and reduced error rates.

Railway and Transport Systems

Constant vibration damages conventional screw terminals. Customized spring clamp blocks with anti-vibration features maintain stable conductivity under mechanical stress.

Commercial and Residential Buildings

Large distribution networks need simplified maintenance. OEM terminal blocks with quick-release designs and modular replacements minimize downtime and increase safety.

Heavy-Duty Machinery

High load and thermal stress require special materials. Heat-resistant alloys and advanced insulation preserve conductivity under continuous operation.

OEM Customization Advantages in Different Sectors

| Industry Sector | Common Challenge | OEM Custom Solution |

|---|---|---|

| Renewable Energy | Heat, UV, outdoor exposure | Flame-retardant, corrosion-proof blocks |

| Automation Panels | Compact layouts, wiring errors | Modular plug-in, color-coded design |

| Transport Systems | Mechanical vibration | Spring clamp with vibration resistance |

| Commercial Buildings | High maintenance needs | Quick-release, modular replacements |

| Heavy-Duty Machinery | High thermal load | Heat-resistant alloys, advanced insulation |

Q&A: Addressing Client Concerns

Q1: How do OEM terminal blocks improve long-term reliability?

By aligning design with industry-specific challenges, OEM blocks reduce failure points. ZhongBo ensures each unit undergoes CE and UL certification testing, including conductivity and insulation checks.

Q2: Can OEM solutions meet global compliance?

Yes. All custom blocks are produced under ISO9001:2015 systems, certified to IEC, CE, and UL standards, ensuring global project compatibility.

Q3: What about scalability for large projects?

With automated production lines and inventory management, ZhongBo integrates OEM adjustments quickly, fulfilling urgent or bulk orders without compromising lead times.

Practical Use Cases in OEM Flexibility

-

A solar energy farm improved uptime by replacing standard connectors with heat-resistant, corrosion-proof AC terminal blocks.

-

An industrial automation plant reduced wiring errors by 20% after adopting modular plug-in blocks.

-

A railway project extended connector life cycles by integrating vibration-resistant spring clamp solutions.

These examples highlight how custom design prevents downtime, lowers maintenance costs, and ensures safety compliance.

Building Value Beyond Components

OEM flexibility is not just about offering more options—it’s about engineering reliability directly into the client’s system. By tailoring AC terminal blocks to different applications, manufacturers ensure compliance, operational efficiency, and safety.

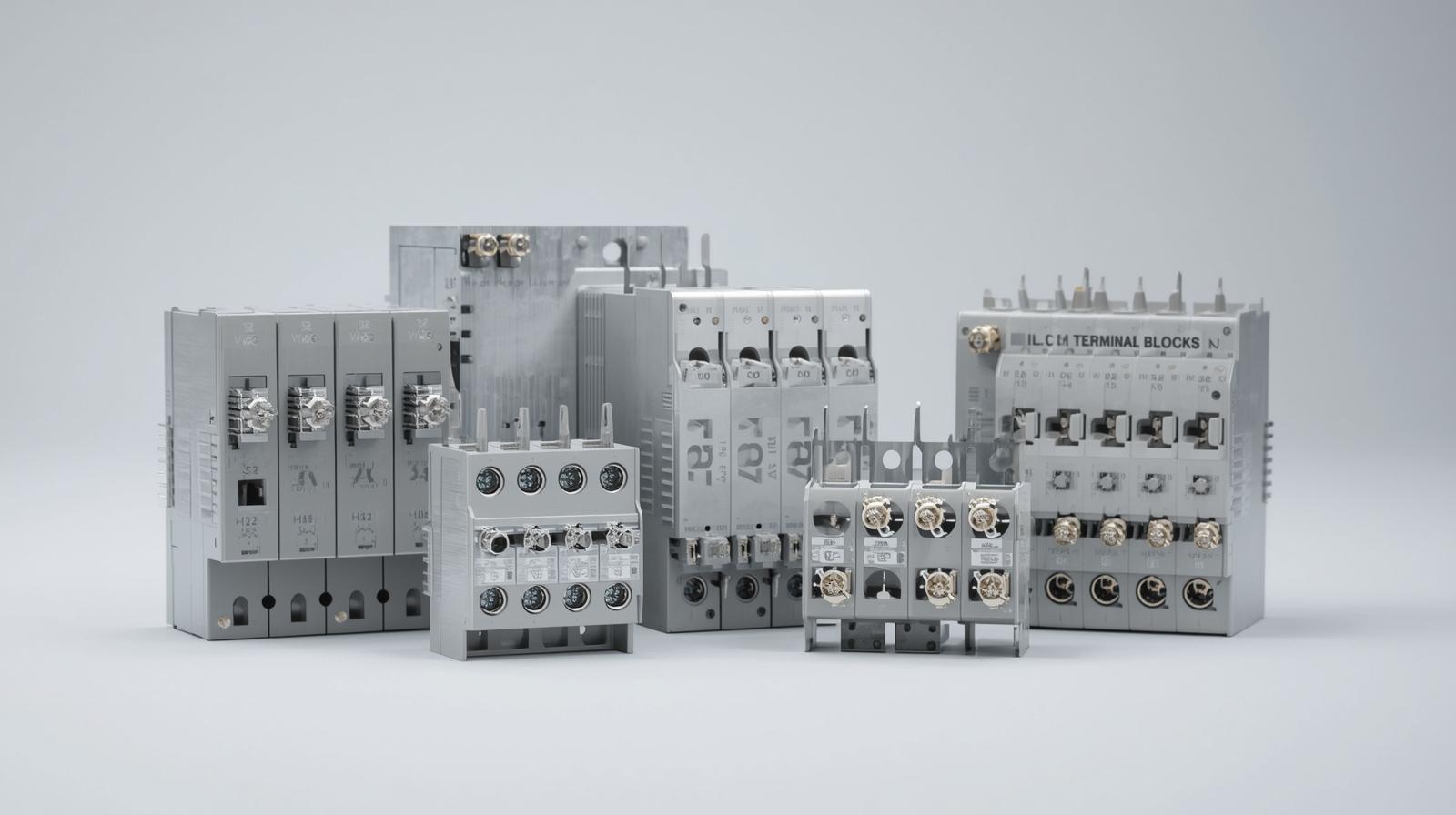

At ZhongBo, we combine CNC machining, automated production, and over 50 advanced testing instruments to create solutions that adapt to diverse real-world conditions. With IEC, CE, and UL certifications, ZhongBo is more than a component supplier—we are a long-term partner for global projects in energy, transport, and automation.

For detailed solutions and technical support, visit our homepage or connect with us directly through our contact page.