Fire and Surge Protection in PCB Mounted Terminal Design

In today’s electronics landscape, safety is not optional—it is engineered into every component. For PCB mounted terminals, two critical aspects—fire resistance and surge protection—determine whether a system can operate safely under real-world stresses.

Engineering Fire Resistance into PCB Terminals

PCB terminals are often placed in dense circuit assemblies where overheating risks are high. Fire-resistant designs focus on:

-

High-temperature polymers: UL94 V-0 certified housing materials that prevent flame propagation.

-

Optimized creepage and clearance distances: Minimizing the chance of arcing between conductive parts.

-

Thermal cycling tolerance: Ensuring that repeated heating and cooling do not degrade material performance.

These measures are particularly important in industrial control cabinets, EV chargers, and renewable energy systems, where prolonged heat exposure is common.

Surge Protection as a Reliability Backbone

Modern electronic systems are vulnerable to voltage spikes from lightning strikes, switching surges, or unstable power grids. To protect sensitive circuits, PCB mounted terminals integrate:

-

Reinforced insulation barriers that withstand transient overvoltages.

-

Metal alloys and plating choices (nickel or gold) that maintain conductivity under stress.

-

Integration with surge arrestors or MOVs within terminal housing for mission-critical equipment.

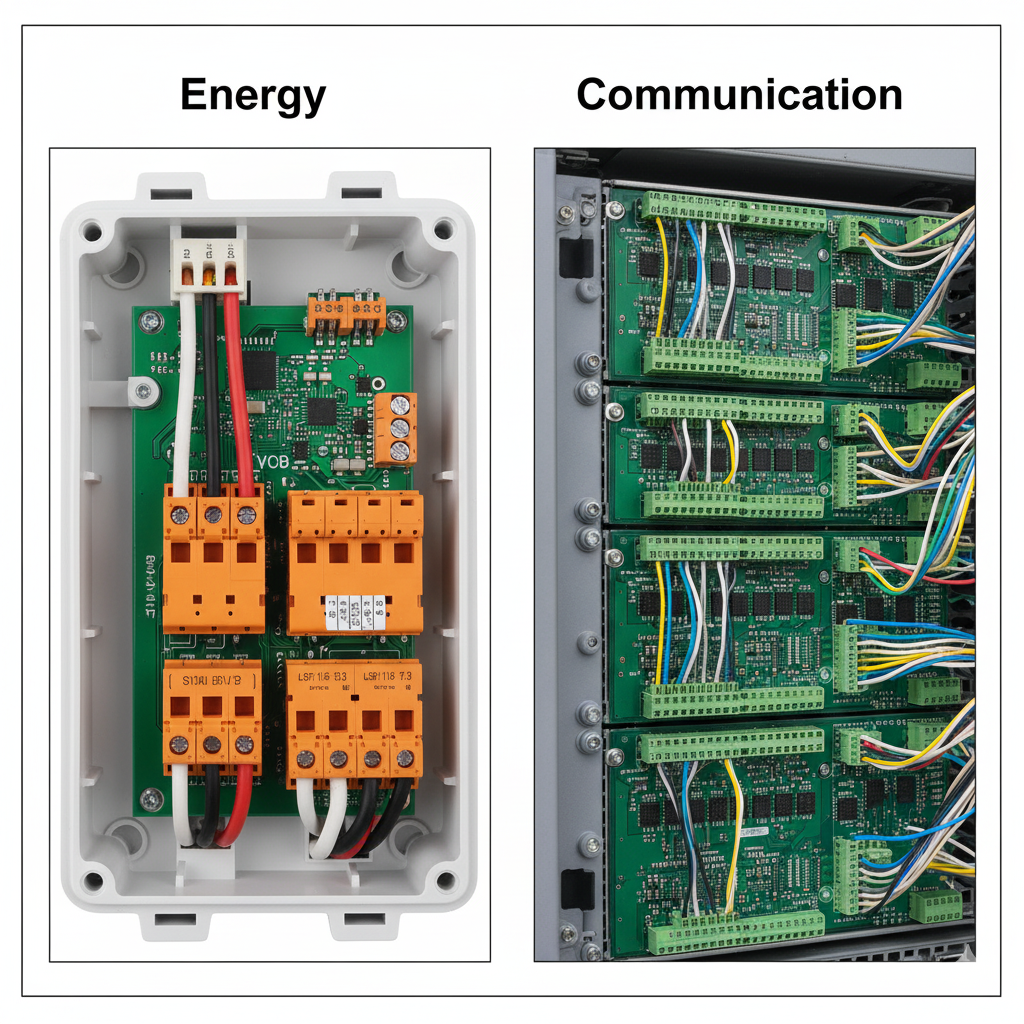

This makes them indispensable in telecommunications, medical electronics, and smart grid systems where uptime and data integrity are paramount.

Application Landscape: Where Safety Comes First

| Application Field | Fire Protection Priority | Surge Protection Priority |

|---|---|---|

| Automotive Electronics | Heat resistance in engine bay modules | Protection against alternator and ignition surges |

| Renewable Energy Systems | Fire-resistant housing in high-temperature panels | Surge handling for solar and wind fluctuations |

| Industrial Automation | Flame-retardant housings in control cabinets | Transient voltage control in heavy machinery |

| Telecom & Data Centers | Prevent flame spread in dense server boards | Guard against grid and switching surges |

This demonstrates that fire and surge protection are not optional add-ons but baseline requirements in safety-critical environments.

Buyer FAQs on Fire & Surge Protection

Q1: Are fire-resistant PCB terminals mandatory for certification?

Yes. UL94 V-0 or equivalent ratings are typically required for compliance in most industrial and automotive sectors.

Q2: Can surge protection be integrated directly into terminals?

For high-reliability applications, terminals can be paired with or designed alongside surge arrestors, ensuring line-level protection.

Q3: Do safety features increase costs significantly?

While materials like high-temperature polymers and gold plating cost more, they reduce long-term failures and compliance risks, often lowering total ownership costs.

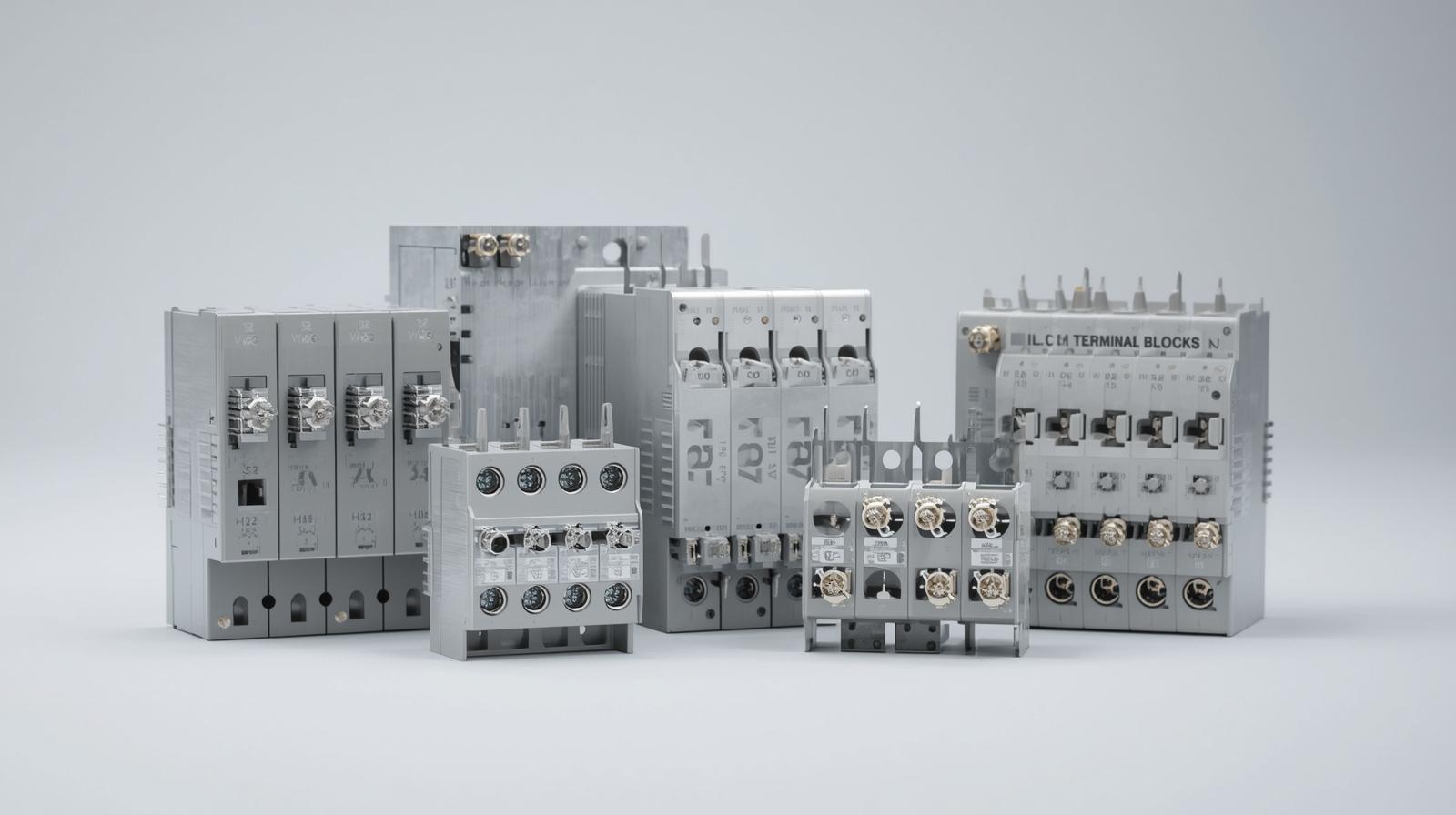

ZhongBo’s Safety-Driven Advantage

At ZhongBo, we specialize in PCB mounted terminals engineered for safety-first environments. Our advantages include:

-

Use of certified flame-retardant materials in all safety-critical product lines.

-

Proven surge-resistant designs validated under international standards.

-

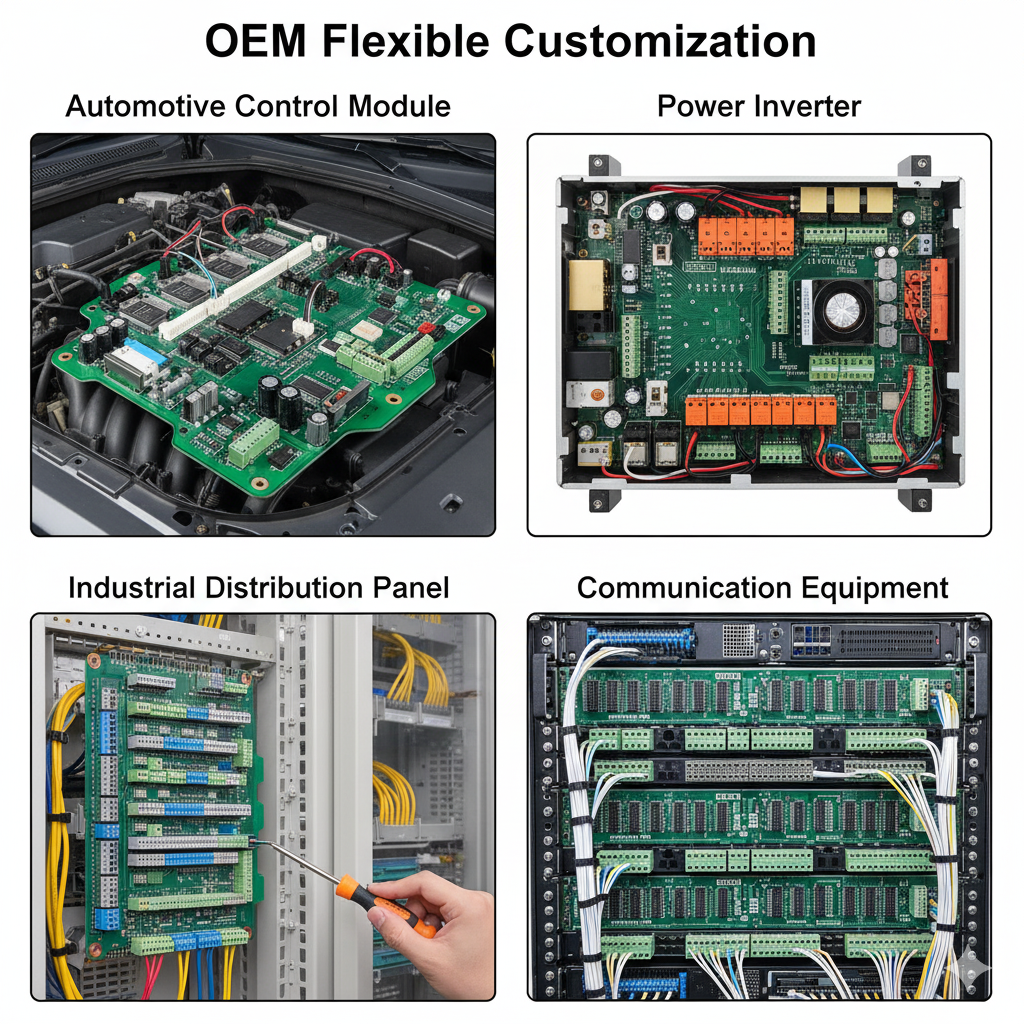

Flexible OEM capabilities to tailor terminals for automotive, renewable energy, and industrial automation sectors.

-

Global supply chain ensuring consistent quality and compliance.

For businesses prioritizing safety in electrical design, ZhongBo offers a proven foundation. Explore our full range of products at ZhongBo’s homepage or reach out directly through our contact page for tailored solutions.