PCB Mounted Terminals: Precision Engineering for Compact Circuits

Engineering Demands of Compact Circuit Design

As electronic devices shrink in size while expanding in functionality, the role of PCB mounted terminals has become more critical than ever. Compact circuits demand connectors that ensure signal integrity, withstand mechanical stress, and optimize space utilization. Engineers face challenges such as heat dissipation in dense layouts, maintaining stable contact resistance, and enabling automated assembly without compromising quality.

Material and Structural Innovations

Advances in plating materials like tin, nickel, and gold ensure corrosion resistance and consistent conductivity for high-density PCBs. Similarly, the use of high-temperature thermoplastics allows terminals to withstand reflow soldering processes. Precision-molded housings minimize footprint while supporting higher pin counts, a key feature for applications like consumer electronics and automotive control modules.

| Key Feature | Engineering Advantage | Application Example |

|---|---|---|

| Gold Plating | Superior conductivity & durability | High-speed data transfer boards |

| Thermoplastics | Reflow soldering stability | Automotive ECUs |

| Miniaturized Housings | Space-saving layouts | Smartphones, IoT devices |

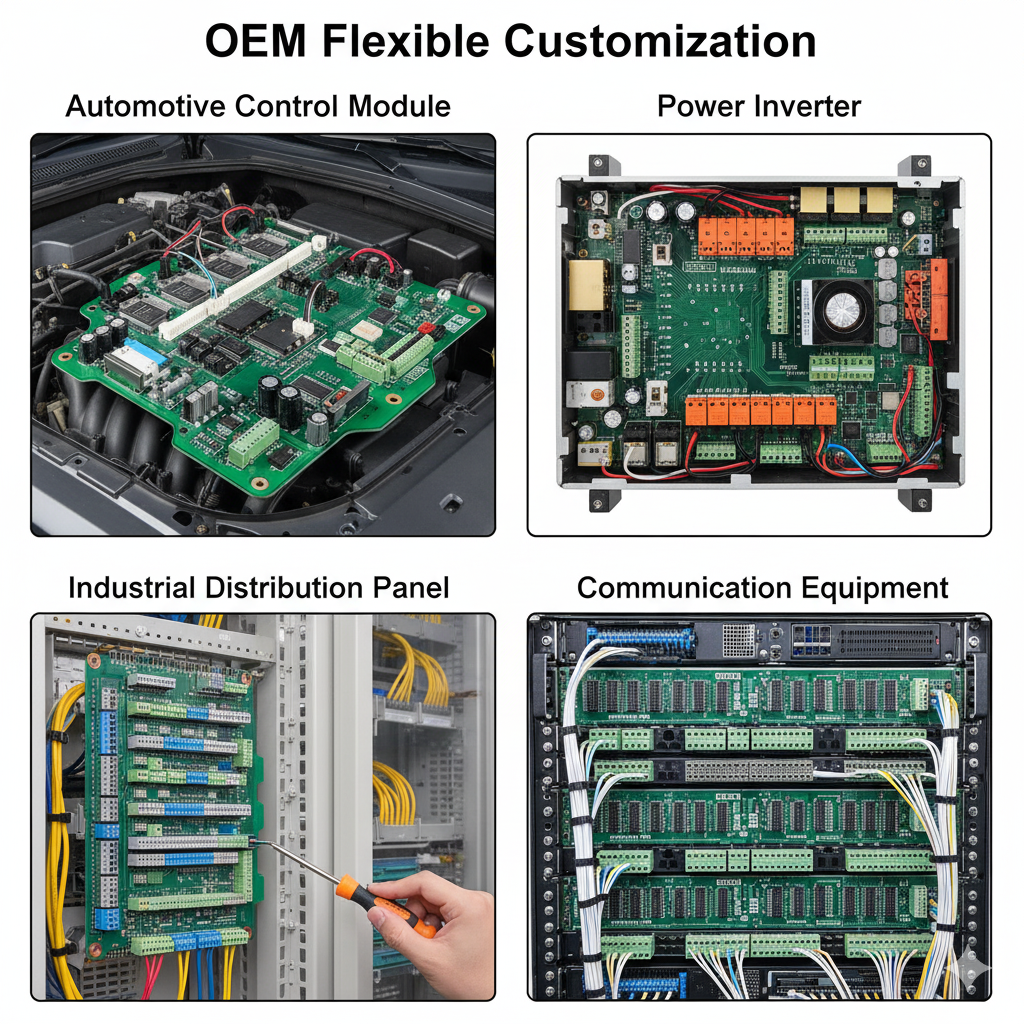

Application-Specific Engineering Challenges

-

Consumer Electronics: PCB terminals must support rapid assembly and cost efficiency while fitting into slim profiles of smartphones and wearables.

-

Automotive Systems: Vibration and temperature extremes require secure locking mechanisms and materials resistant to thermal cycling.

-

Industrial Automation: High current loads in compact PCBs call for terminals designed for heat dissipation and long operational life.

Each sector presents unique demands, and OEM flexibility in terminal block design ensures that customized solutions meet industry-specific standards.

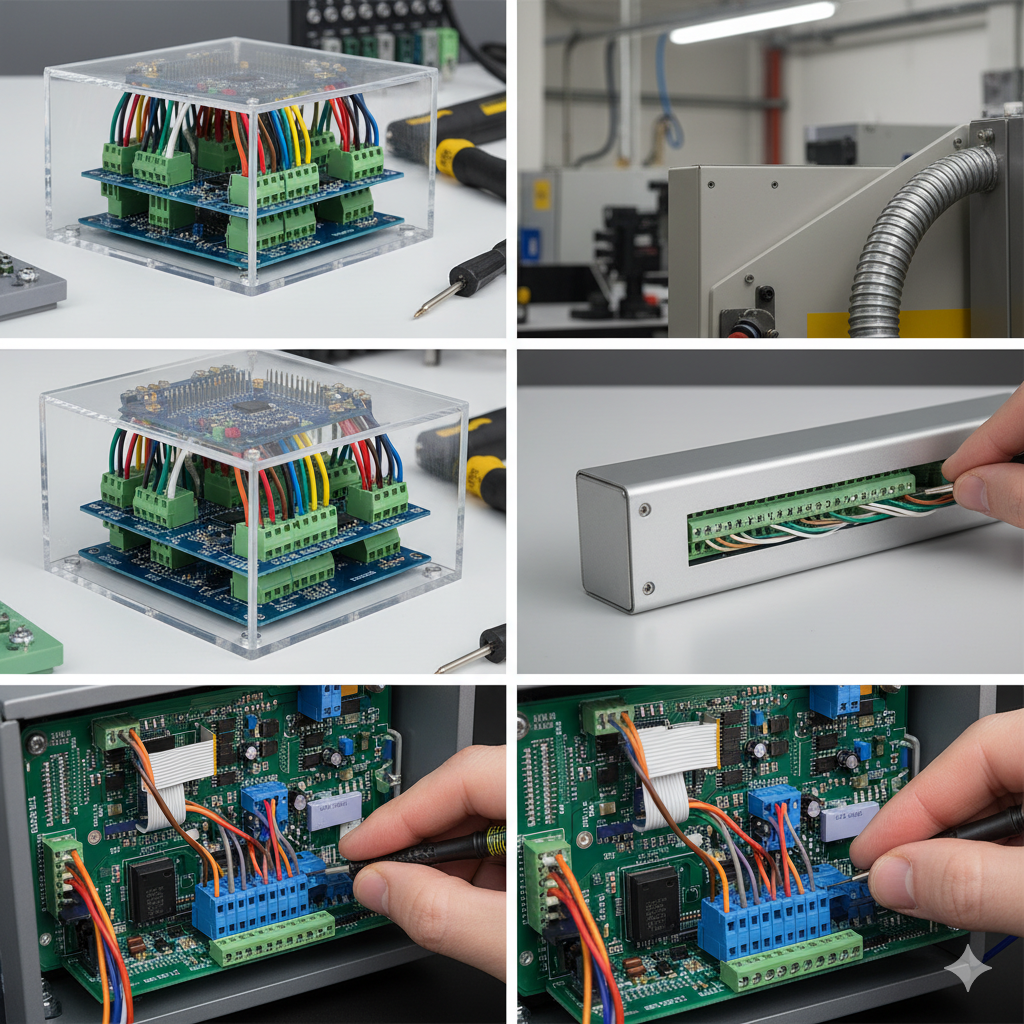

Enhancing Assembly and Maintenance Efficiency

To support modern production lines, PCB mounted terminals are engineered for compatibility with automated pick-and-place systems. Push-in and snap-fit options reduce soldering defects, while test points integrated into terminal blocks allow for faster quality control. In maintenance scenarios, modular designs enable component replacement without desoldering entire assemblies, saving time and cost.

Buyer Concerns and Technical Answers

Q: How can compact PCB terminals ensure reliability under high current?

A: By using copper alloy contacts with optimized cross-sections, terminals maintain conductivity while limiting heat buildup.

Q: Are miniaturized terminals harder to assemble?

A: Automated handling and surface-mount designs eliminate most manual assembly risks, making them even more efficient than larger alternatives.

Q: What makes premium terminals worth the investment?

A: Long-term ROI is achieved through lower failure rates, reduced warranty claims, and compliance with international safety standards (IEC, UL).

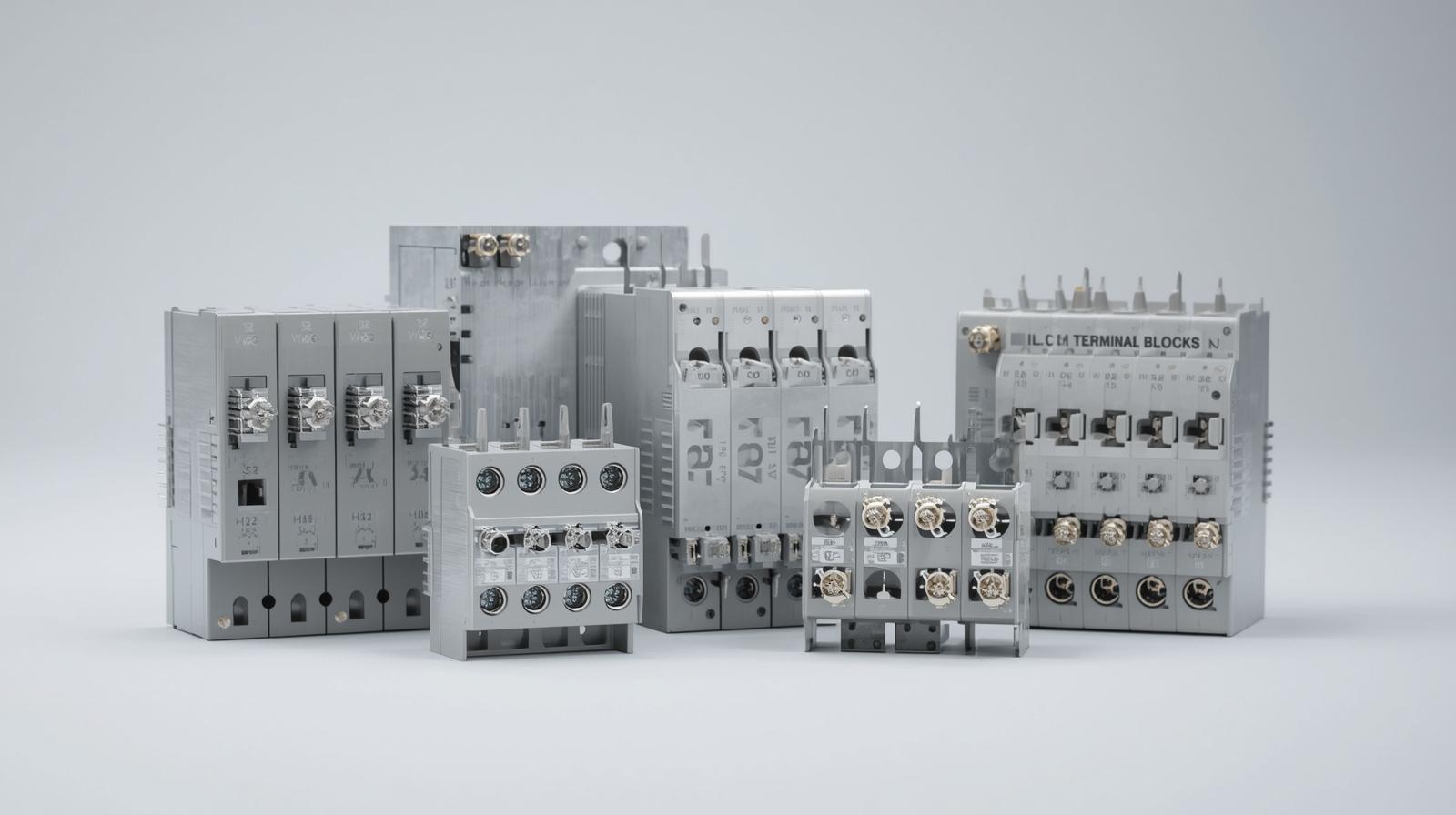

ZhongBo’s Advantage in PCB Mounted Terminal Engineering

At ZhongBo, our expertise lies in delivering OEM-ready PCB mounted terminals engineered for compact, high-performance circuits. With advanced molding capabilities, rigorous testing protocols, and compliance with global standards, we support customers across electronics, automotive, and industrial markets. By combining precision engineering with scalable manufacturing, we provide solutions tailored to diverse client needs.

To explore our full range of terminal solutions, visit our homepage or contact our team directly via contact us.