How Plating Materials Impact PCB Terminal Block Reliability

Material Choices that Define Long-Term Performance

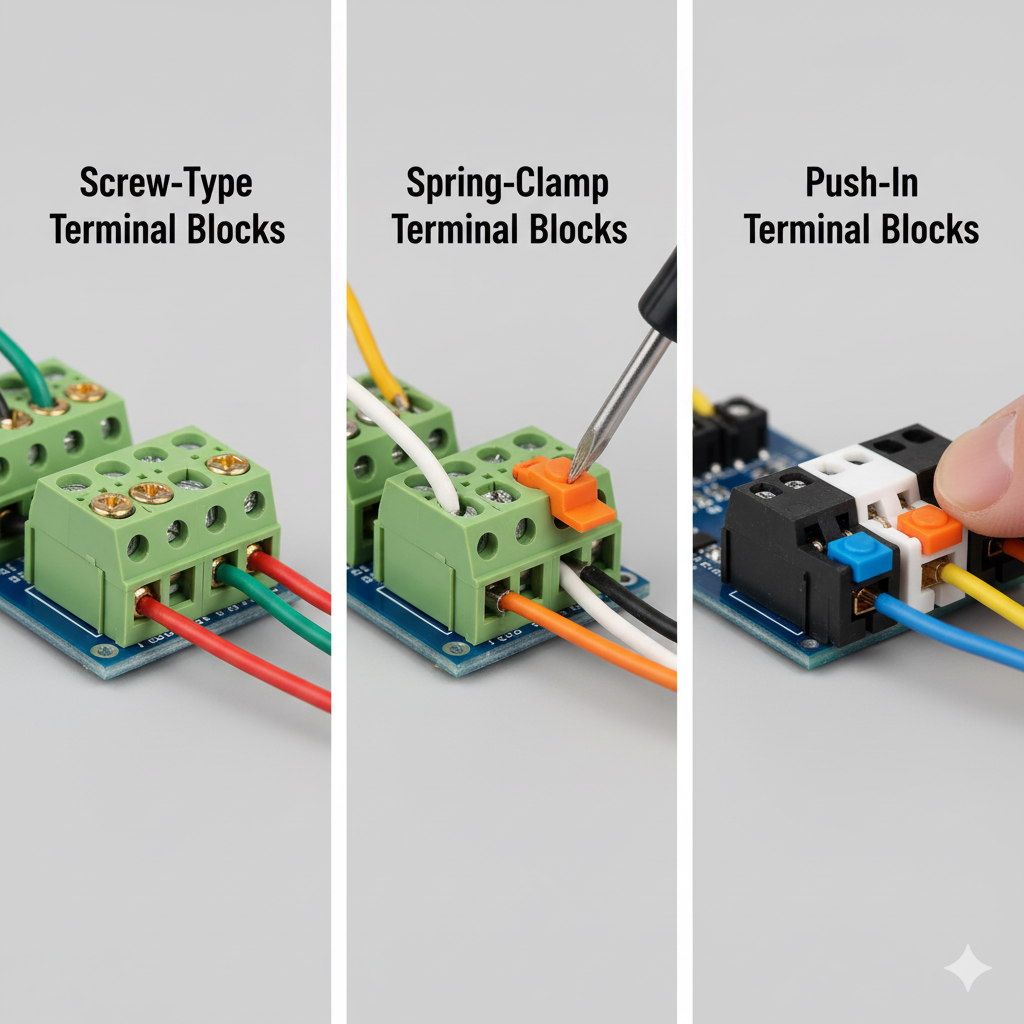

In PCB terminal block manufacturing, plating material is more than a finishing detail — it directly shapes conductivity, corrosion resistance, and lifecycle reliability. Gold, tin, nickel, and silver remain the most common options, each serving distinct operating environments. For instance, gold plating excels in low-voltage signal integrity, while tin plating provides cost-effective resistance for general industrial use. Selecting the right plating isn’t just about price — it determines whether circuits operate seamlessly in demanding conditions or degrade under stress.

Addressing Corrosion and Environmental Challenges

One of the most persistent risks in terminal block reliability is environmental corrosion, especially in humid, coastal, or industrial chemical environments. Nickel underlayers and silver finishes offer strong protection against oxidation, while gold remains the benchmark for preventing surface degradation. OEM clients working in renewable energy, offshore equipment, or transport electronics often demand tailored plating solutions that withstand exposure without compromising connection stability.

Balancing Conductivity and Mechanical Strength

Electrical conductivity must be paired with structural robustness. Silver offers the lowest resistance but tarnishes easily, requiring additional surface treatments. Tin provides flexibility but risks whisker growth over time if not carefully controlled. By integrating plating thickness control and multi-layer combinations, manufacturers ensure both signal performance and mechanical endurance, particularly in automotive PCB assemblies, industrial control boards, and consumer electronics.

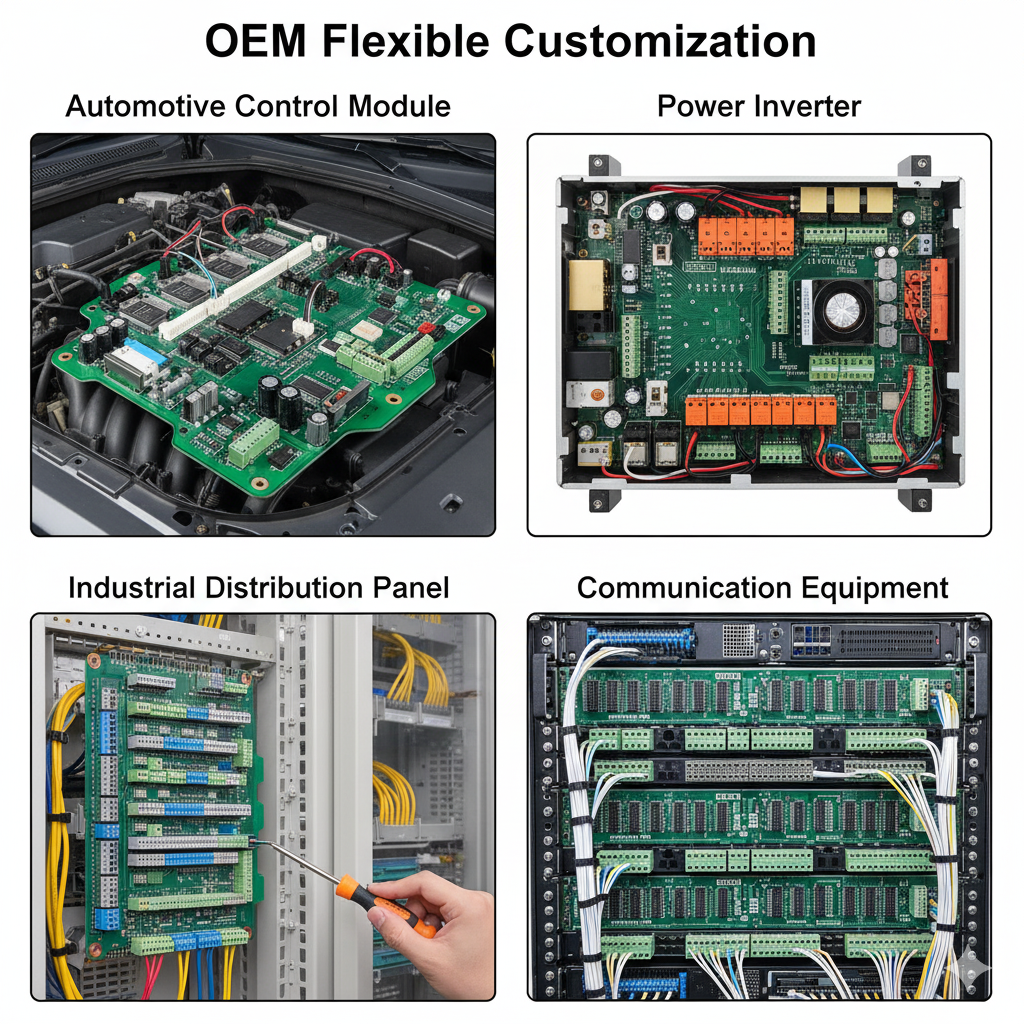

OEM Solutions: Customizing for Industry Needs

Different industries prioritize different plating benefits.

-

Automotive: High vibration resistance and temperature stability, often requiring nickel or multi-layer finishes.

-

Telecommunications: Signal clarity and low resistance, leading to gold or silver-plated contacts.

-

Industrial automation: Corrosion and wear protection for continuous mechanical engagement, usually tin or nickel.

This application-driven plating strategy ensures that each PCB terminal block can deliver reliability without overspending on unnecessary materials.

Technical Comparison of Plating Materials

| Plating Material | Key Advantage | Limitation | Typical Application |

|---|---|---|---|

| Gold | Excellent conductivity, anti-corrosion | High cost | Telecom, aerospace, signal boards |

| Tin | Affordable, flexible use | Whisker growth risk | Industrial, consumer electronics |

| Nickel | Corrosion barrier, durable | Moderate conductivity | Automotive, power electronics |

| Silver | Superior conductivity | Tarnishing over time | High-current systems, telecom |

Expert Insights and Buyer Questions

Q: How does plating thickness affect reliability?

A: Thicker plating layers generally improve durability, but excessive thickness can lead to fitment issues or higher costs. Precision control ensures balance.

Q: Why not always use gold if it’s the most reliable?

A: Gold is effective but costly. For high-volume applications like consumer electronics, tin or nickel provides sufficient protection at lower cost.

Q: How can OEMs decide on plating materials?

A: The choice depends on environment, electrical load, and product lifespan. Partnering with an experienced supplier ensures data-driven recommendations rather than generic solutions.

Building Reliability with ZhongBo

At ZhongBo, we engineer PCB terminal blocks with plating solutions tailored to industry demands. Whether your priority is corrosion resistance, high signal integrity, or long-term mechanical stability, our team designs materials and processes that align with your application. By combining precision plating control and OEM flexibility, we help clients scale from prototype to mass production with confidence. Learn more about our solutions at ZhongBo homepage or connect directly through our contact page.