OEM Flexibility in Screw Type Terminal Blocks: From Compact Panels to Heavy-Duty Power Systems

Why OEM Flexibility Matters

Electrical projects rarely follow a “one-size-fits-all” rule. From small-scale automation cabinets to power-hungry substations, each system has unique demands. Standard terminal blocks often fall short—too large for compact panels, too weak for heavy loads, or lacking proper certification for international projects.

OEM screw type terminal blocks address these pain points by adapting design, size, material, and compliance from the start. This flexibility ensures reliability in diverse environments, turning a basic connector into a critical link in safe and efficient power distribution.

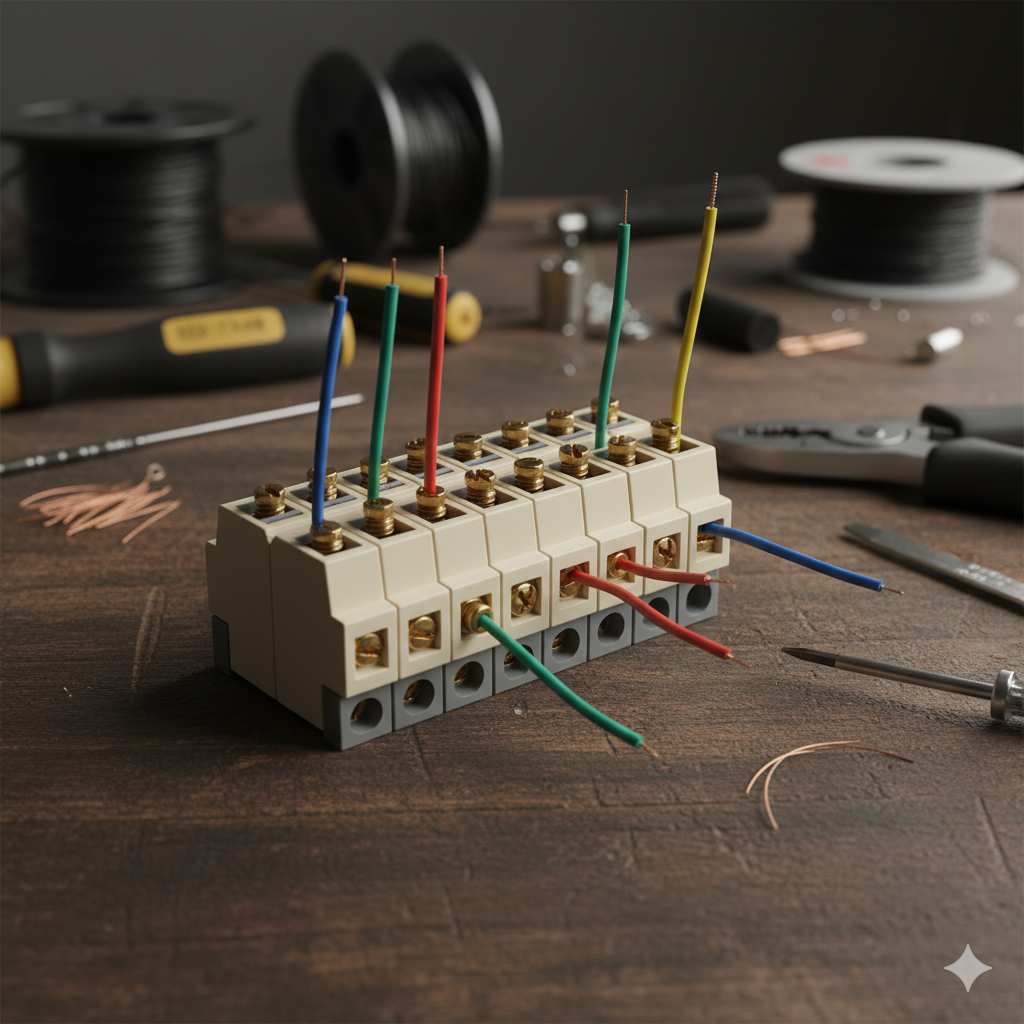

Compact Panels: Maximizing Space Without Sacrificing Safety

In industrial automation or building control, space inside cabinets is a common pain point. Overcrowded wiring increases risks of overheating, miswiring, and costly downtime.

OEM solutions for compact panels offer:

-

Reduced footprints for higher wiring density without compromising insulation distances.

-

Color-coded layouts and clear OEM labeling that simplify maintenance.

-

Custom insulation materials to maintain conductivity under limited ventilation.

By fitting terminals precisely to cabinet requirements, OEM connectors minimize errors and make maintenance faster—cutting costs over the project’s lifecycle.

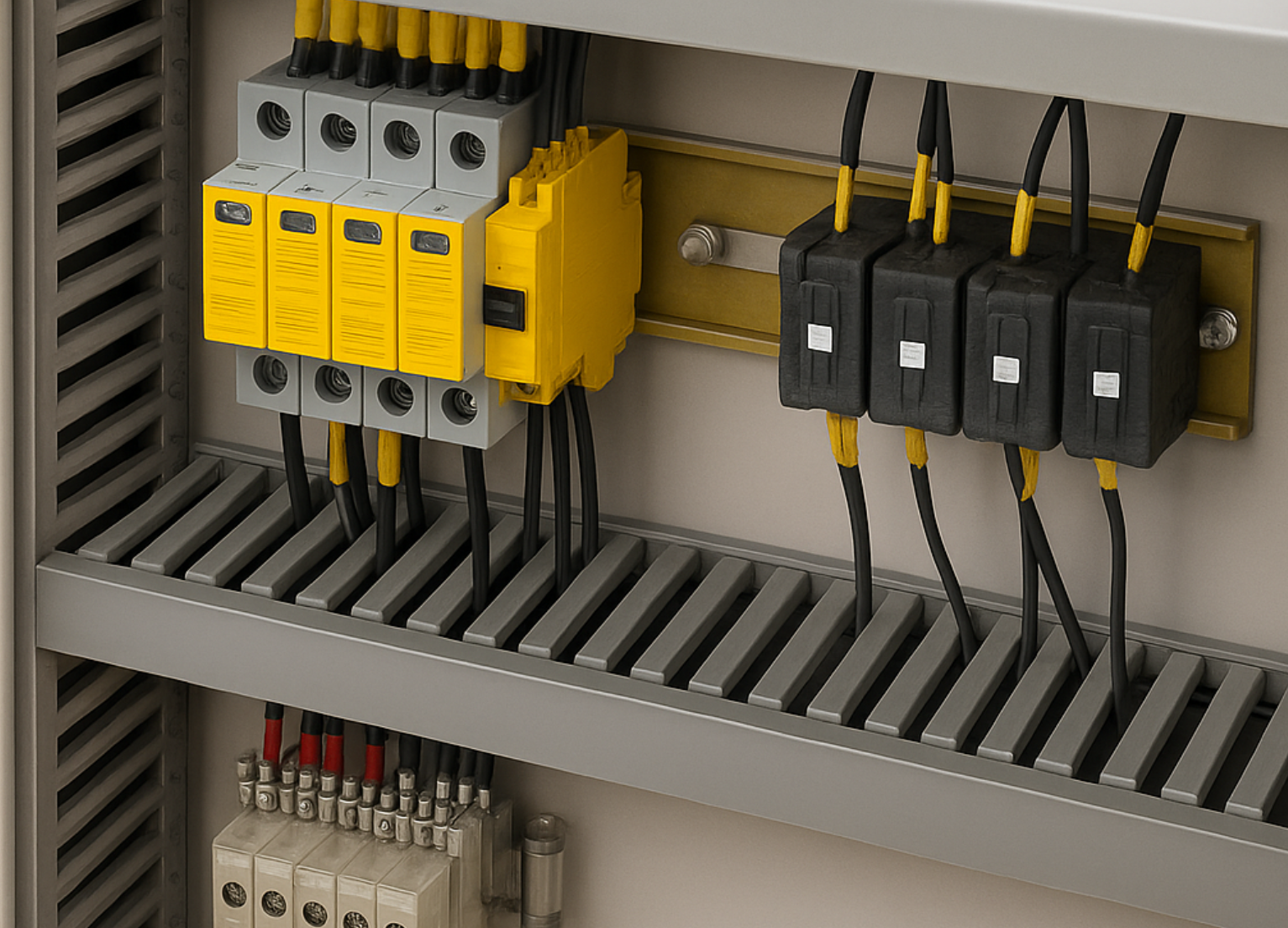

Heavy-Duty Power Systems: Built to Handle Stress

Large energy systems such as renewable inverters, substations, and industrial plants demand connectors that endure heat, current surges, and outdoor exposure. Standard components often fail after months of stress, creating downtime and safety risks.

OEM screw type terminal blocks for heavy-duty use integrate:

-

High-current screw terminals with reinforced contacts.

-

Corrosion-resistant alloys for humid or outdoor climates.

-

Heat-resistant housings that sustain performance under constant load.

-

Compliance aligned with IEC and UL standards for global deployment.

These adaptations ensure heavy-duty systems operate reliably, even in harsh environments with fluctuating demand.

OEM vs Standard Supply

| Factor | Standard Screw Type Block | OEM Screw Type Terminal Block |

|---|---|---|

| Design Options | Generic, limited sizes | Tailored dimensions for panels & systems |

| Load Handling | Basic current capacity | Reinforced, high-current models |

| Compliance | General CE mark only | Full IEC/UL/ISO certifications |

| Brand Integration | None | OEM labeling, packaging & bulk supply |

| Lifecycle Value | Short-term fit | Long-term savings, reduced downtime |

This comparison demonstrates that OEM is not a cosmetic option but a strategic investment in project reliability.

Common Questions Answered

Q1: Why choose OEM instead of standard screw type blocks?

Because OEM connectors solve real pain points. They optimize space in compact cabinets, provide higher current ratings for energy systems, and ensure compliance with IEC/UL certifications—reducing the risk of failure and costly delays.

Q2: How does OEM affect long-term project costs?

Although OEM may have a higher upfront cost, it reduces downtime, lowers maintenance expenses, and ensures bulk supply consistency. Over time, OEM blocks deliver a better return on investment.

Q3: Can OEM designs handle international projects?

Yes. At ZhongBo, every OEM screw type terminal block is tested under ISO, CE, UL, and IEC standards, ensuring products can be deployed globally without additional certification hurdles.

Building Trust Through OEM Partnerships

Electrical connections may be small, but their impact on system safety and uptime is significant. OEM screw type terminal blocks provide the flexibility to adapt to compact panels, the strength to withstand heavy-duty environments, and the compliance to meet global standards.

At ZhongBo, OEM solutions are supported by CNC machining, automated production lines, and more than 50 testing instruments to verify conductivity, insulation, and thermal resistance. Every product batch is systematically tested and certified, ensuring clients receive not only components but reliable solutions for critical industries.

For tailored OEM solutions in screw type terminal blocks, explore our homepage or contact us through the contact page.