Why Cage Spring Terminal Blocks Are the Preferred Choice for Modern Automation Systems

Eliminating Loose Connections in High-Vibration Industries

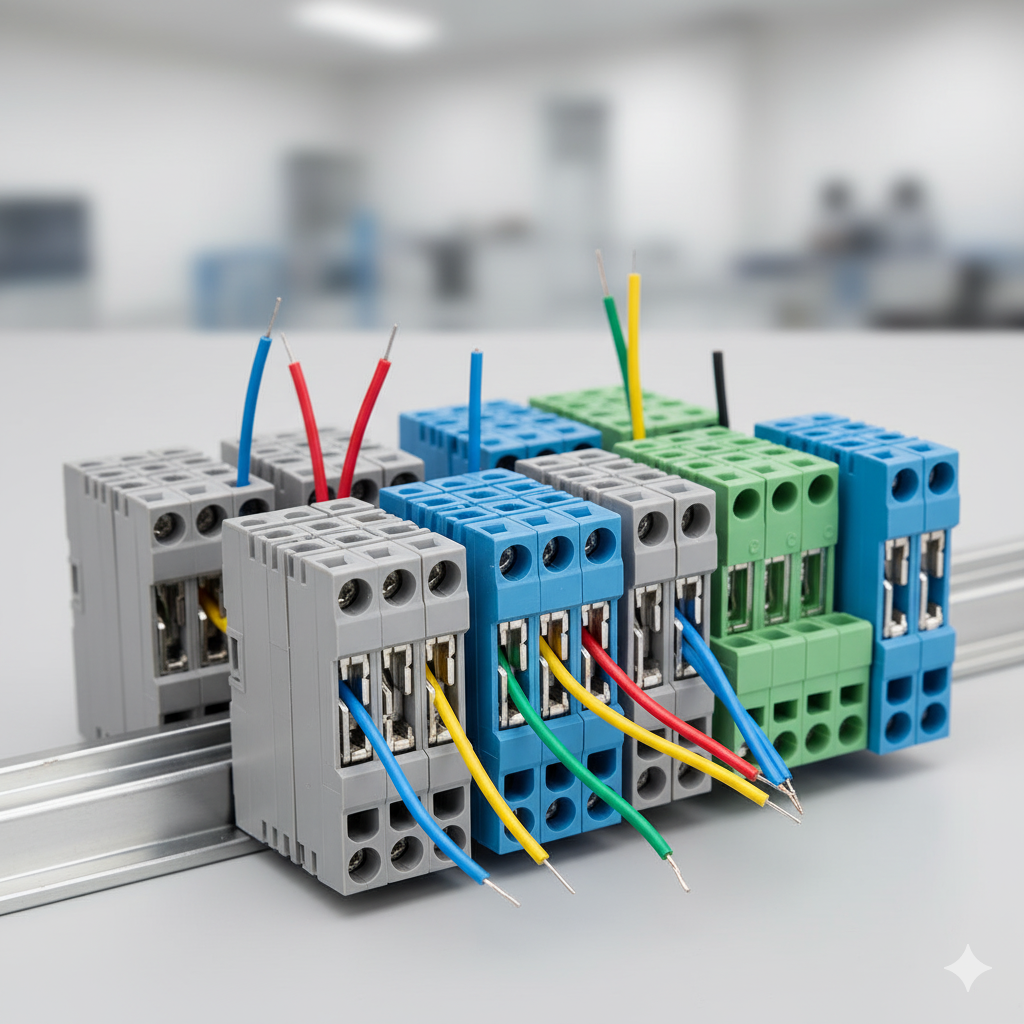

In industries like rail transport, wind power, and heavy automation, one of the biggest risks is wiring loosening over time. Traditional screw-based terminals may gradually lose torque, leading to intermittent failures. Cage spring terminal blocks address this pain point by applying constant pressure through their spring mechanism, ensuring conductors remain securely clamped even under continuous vibration. This reduces downtime and maintenance costs, which is why manufacturers in sectors such as renewable energy and industrial robotics increasingly adopt them.

Tool-Free Wiring That Saves Time in Mass Production

Assembly speed directly impacts production costs in automation and electrical equipment manufacturing. Cage spring terminals allow push-in wiring without torque tools, cutting installation time by up to 30% compared to screw-based designs. For large control cabinets, this difference translates into thousands of hours saved annually. Beyond cost efficiency, tool-free wiring also improves worker safety by reducing torque errors and preventing overtightened or undertightened connections.

Example Scenario: A manufacturer of modular conveyor systems reported faster cabinet assembly cycles when replacing traditional screw terminals with cage spring blocks, allowing quicker delivery schedules without compromising quality.

Global Compliance for Export-Oriented Projects

Automation projects often cross borders, and compliance with international standards is non-negotiable. Cage spring terminal blocks are widely certified under UL, IEC, and CE standards, making them compatible with global supply chains. This advantage helps export-driven integrators avoid additional requalification testing, speeding up time-to-market while ensuring end customers receive equipment that meets stringent safety benchmarks.

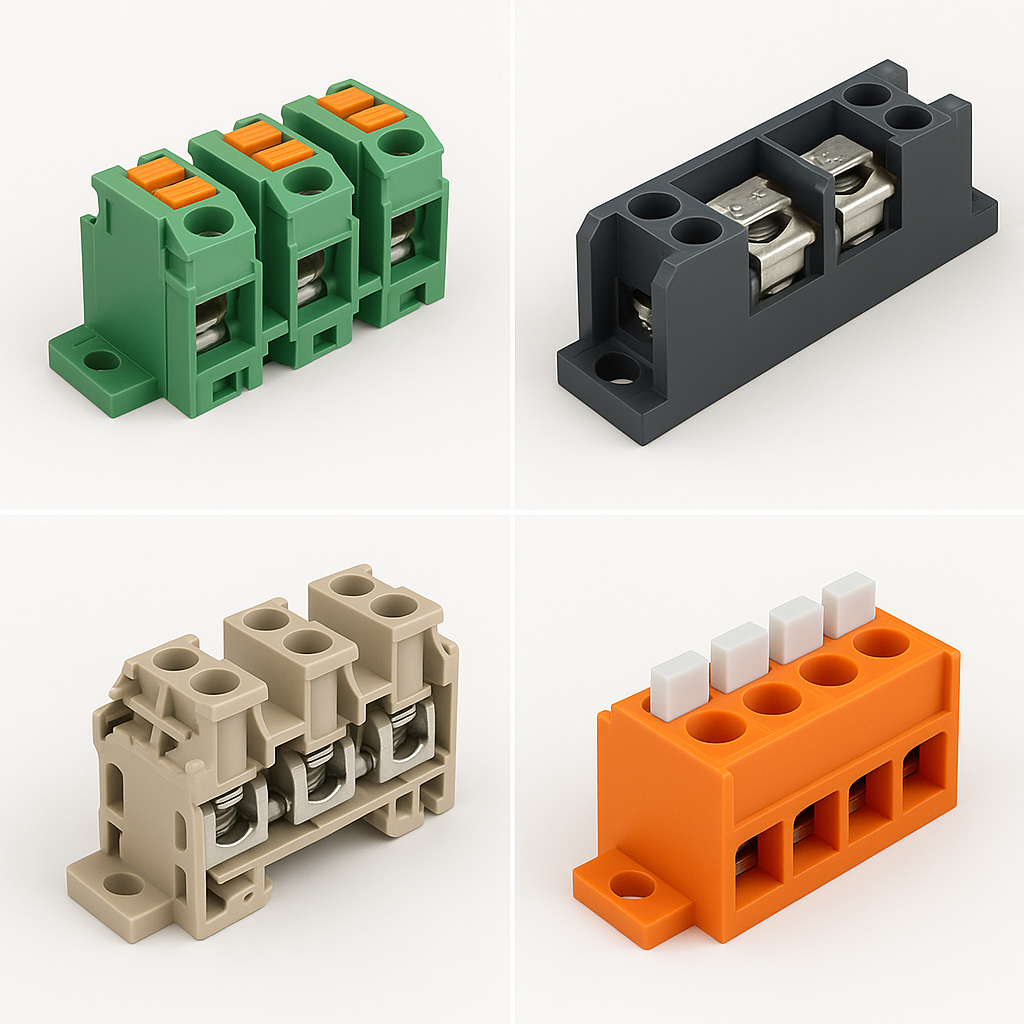

Diverse Applications Across Power and Control Systems

Cage spring terminals are not limited to a single sector; they are widely deployed across automation and energy ecosystems. Their advantages differ by environment:

| Industry Sector | How Cage Spring Terminal Blocks Add Value |

|---|---|

| Factory Automation | Secure wiring under constant vibration; reduced maintenance cycles |

| Renewable Energy | Stable connections in inverters and solar arrays; tool-free field installation |

| Transport Systems | Reliable under shock and vibration in rail and EV charging infrastructure |

| Building Automation | Compact size for space-saving in HVAC and smart grid systems |

This versatility ensures engineers can specify a single connector type across multiple systems, simplifying procurement and reducing spare parts complexity.

Addressing Buyer Questions with Practical Insights

Q1: Do cage spring terminals work with different wire sizes?

Yes, they support a wide range of conductor cross-sections, making them flexible for mixed wiring environments.

Q2: How do they perform in harsh outdoor applications?

Their corrosion-resistant design and consistent contact pressure ensure durability even in environments with temperature fluctuations.

Q3: Are they suitable for high-current applications?

While commonly used for control and signal wiring, advanced cage spring designs can handle significant current loads when properly specified.

Why ZhongBo Stands Out in Cage Spring Technology

At ZhongBo, we go beyond standard manufacturing. Our cage spring terminal blocks are engineered with precision springs, tested for vibration endurance, and produced under scalable capacity to support both small-batch customization and large-scale global supply. With a focus on export-driven reliability, we help customers in automation, renewable energy, and transport build systems that perform consistently over decades.

To explore more about our solutions, visit our homepage or connect with us directly through our contact page.