From 10 to 60 Series: How Plug-In Terminal Blocks Support Versatile Power and Control Systems

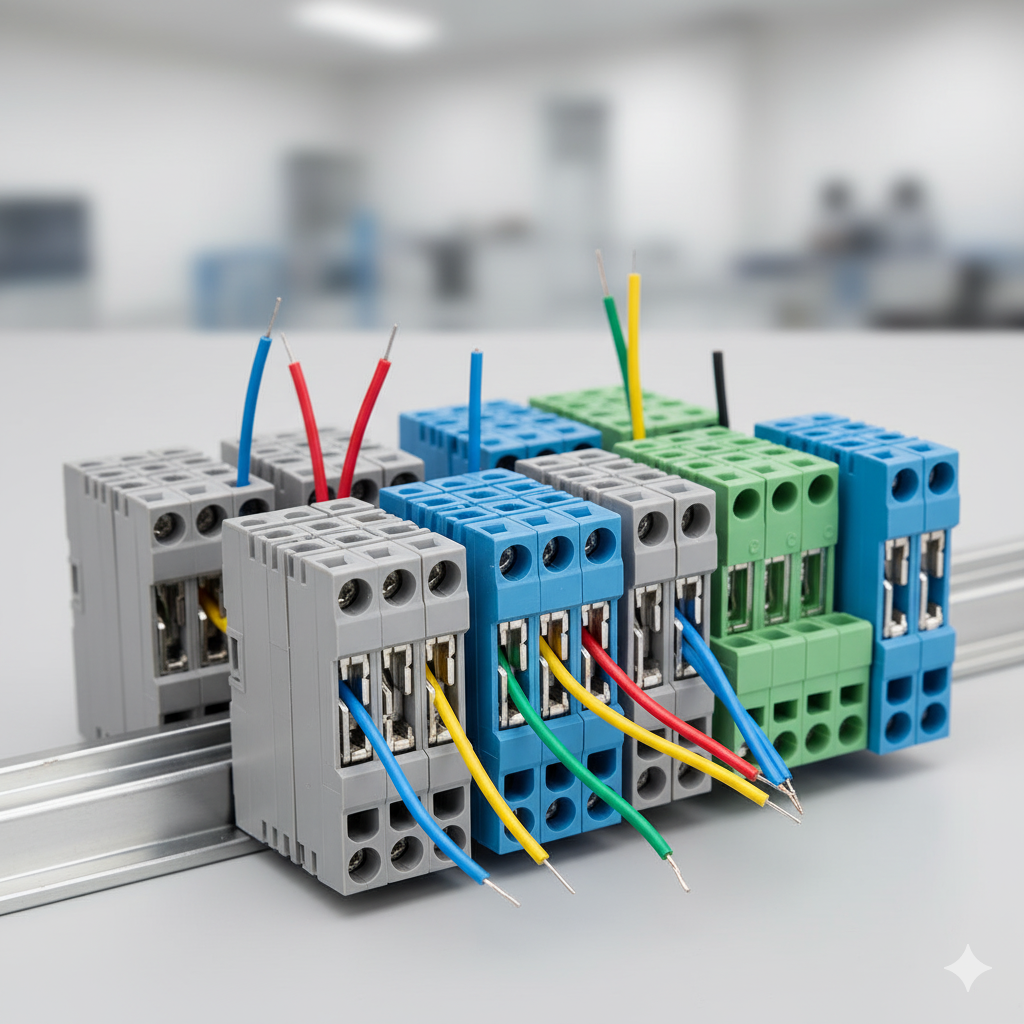

Plug-in terminal blocks have become indispensable in today’s power distribution and control systems. Their modularity and quick-connect design allow engineers to reduce downtime, improve wiring efficiency, and maintain safety across a wide range of industrial and commercial environments. Within this category, the 10, 20, 25, and 60 Series have emerged as benchmarks, each addressing different operational needs—from compact automation cabinets to heavy-duty power infrastructure.

Why Plug-In Terminal Blocks Are Reshaping Wiring Practices

In the past, fixed screw connections dominated electrical panels. While secure, they were time-consuming and difficult to reconfigure. Plug-in terminal blocks solve these challenges by enabling tool-free connections that can be replaced or scaled without disrupting the entire system. This feature is particularly valuable in sectors where uptime directly affects productivity, such as factory automation, renewable energy, and transport infrastructure.

More importantly, these blocks are designed with consistent clamping force, tested insulation resistance, and flame-retardant materials, ensuring long-term reliability in both indoor and outdoor applications.

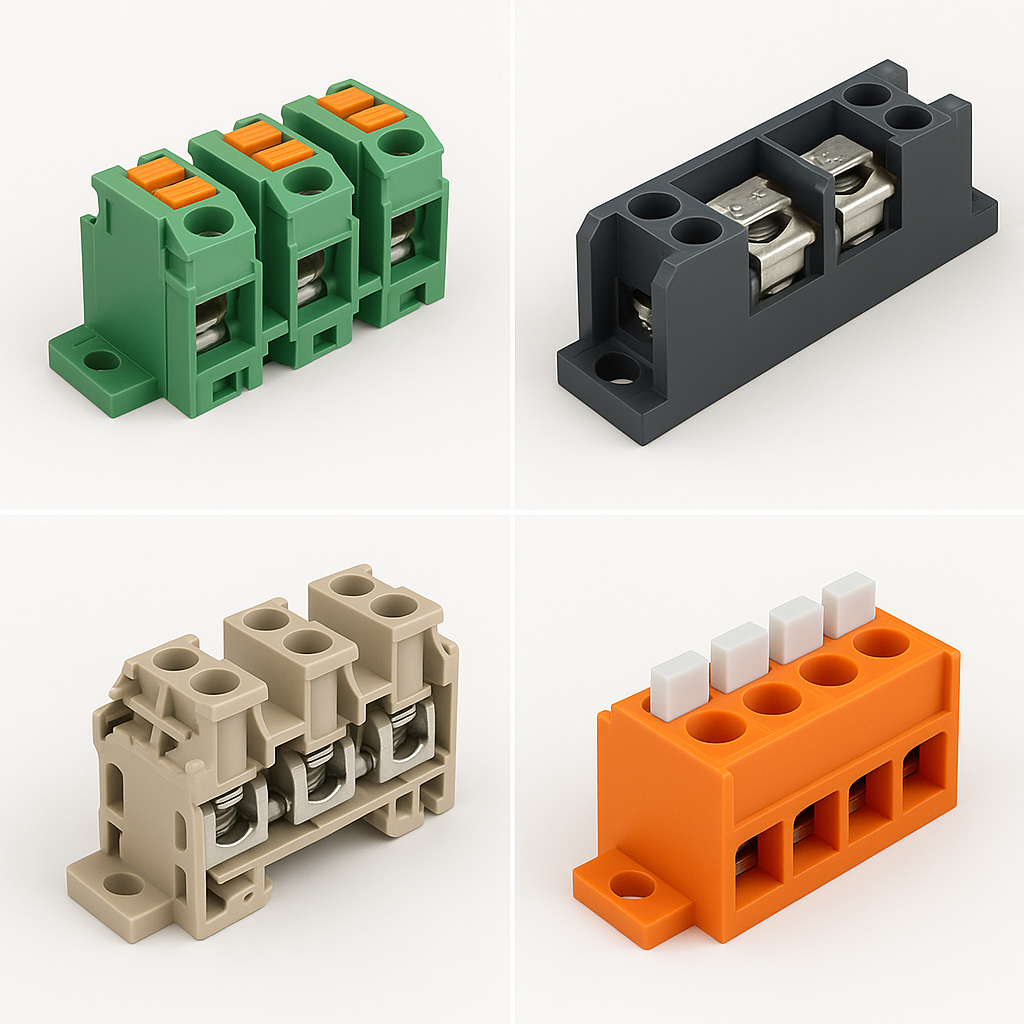

The Distinct Roles of the 10, 20, 25, and 60 Series

Each series reflects a balance of size, current capacity, and application suitability. Instead of treating them as interchangeable, engineers align their choice with project-specific demands.

| Series | Strengths | Key Industries |

|---|---|---|

| 10 Series | Ultra-compact design, optimized for tight spaces | Building automation, electronics, small control units |

| 20 Series | Mid-range solution balancing footprint and load | Lighting systems, HVAC, general automation panels |

| 25 Series | Higher current handling with robust build | Industrial machinery, conveyor systems, transport equipment |

| 60 Series | Heavy-duty structure for high-load power | Renewable energy storage, substations, heavy equipment |

By offering this variety, manufacturers give project managers the ability to scale from small control signals to large power circuits without switching wiring philosophies.

Practical Challenges Addressed by Plug-In Solutions

-

Time pressure during installation – Plug-in blocks cut wiring time significantly compared to screw-based connections.

-

Maintenance in live environments – Engineers can safely disconnect and reconnect modules with minimal downtime.

-

System expansion – Modular series allow adding new loads or circuits without redesigning the entire distribution cabinet.

-

Compliance with international standards – Certified testing for heat, vibration, and insulation ensures global acceptance.

These qualities reduce risks not just during installation, but throughout the lifecycle of the system.

Industry Applications: Where Each Series Excels

-

Energy Systems – The 60 Series is widely used in solar inverters and battery cabinets, where stable high-current capacity is essential.

-

Factory Automation – The 25 Series supports robotics, conveyor drives, and programmable logic controller (PLC) wiring.

-

Commercial Buildings – The 10 and 20 Series streamline HVAC, security, and lighting systems where space is limited.

-

Transport Infrastructure – Rail operators often rely on the 25 and 60 Series due to vibration-resistant design and long-term durability.

By mapping the right product to the right environment, users achieve a balance between performance, safety, and cost efficiency.

Buyer Concerns and Expert Answers

Q1: How do I ensure compatibility across different series?

Manufacturers provide standard pin layouts and coding options to prevent mismatched connections, ensuring safe interchangeability.

Q2: What about long-term durability in harsh environments?

Housing materials are engineered with UV and flame resistance, while conductive parts undergo anti-oxidation treatments to maintain performance.

Q3: Can I order customized designs?

Yes, OEM services allow adjustments in pin count, pitch, and housing material to match unique industrial requirements.

Engineering Reliability with ZhongBo

As a global manufacturer, ZhongBo has integrated automated production lines, CNC precision tooling, and multi-step quality inspections into its terminal block production. Each series undergoes testing for electrical strength, vibration resistance, and thermal performance, ensuring compliance with IEC and UL standards.

From compact 10 Series modules to robust 60 Series power solutions, ZhongBo provides not only a product, but a scalable wiring platform tailored for modern industries. For companies seeking durable, customizable, and globally certified solutions, ZhongBo offers the reliability to power systems today and in the future.

To explore more about our plug-in terminal block portfolio, visit our homepage or get in touch via our contact page.