Connecting Safety and Scale: Screw Terminal Blocks in Modern Energy and Automation Projects

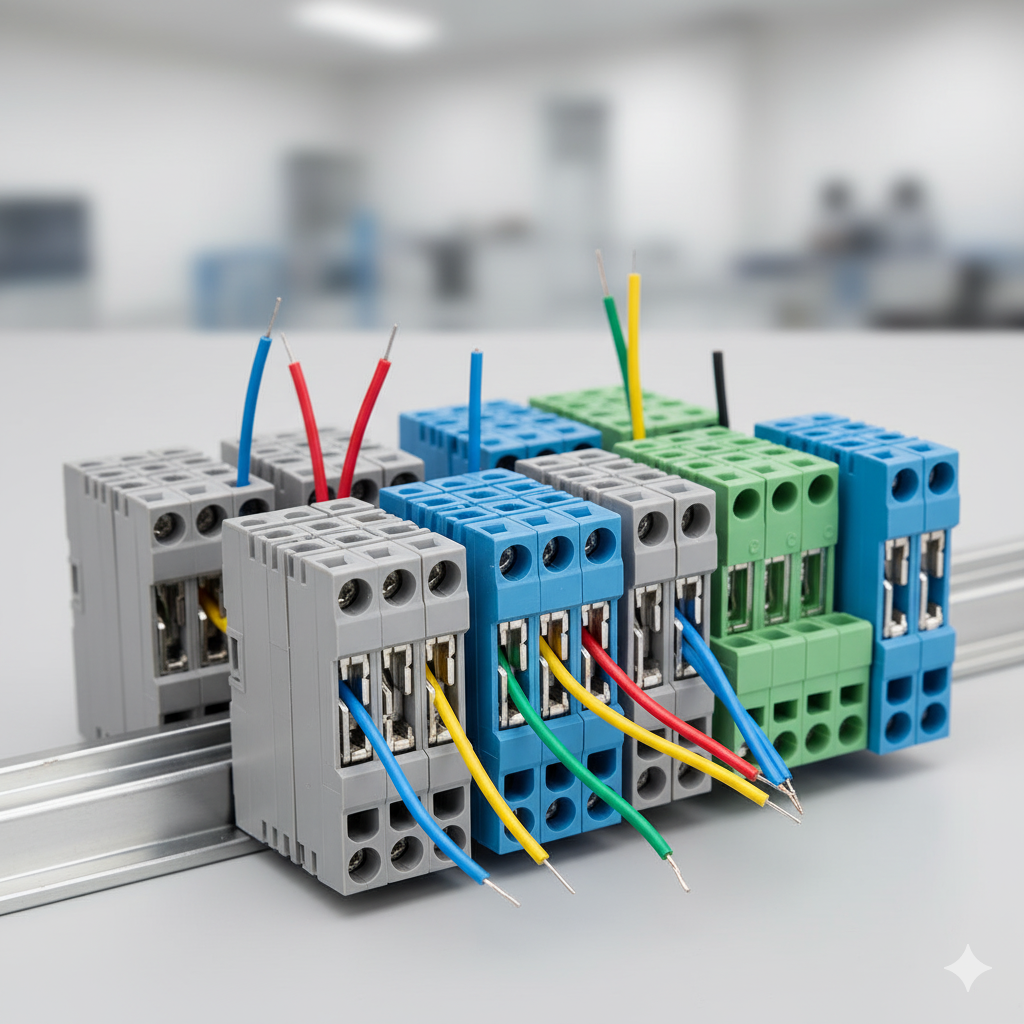

Why Safety Cannot Be Compromised in Industrial Wiring

Energy and automation systems operate in environments where failure is not an option. From factory control lines to renewable energy plants, wiring integrity determines whether a system can run continuously and safely. Screw terminal blocks solve common problems such as loose connections, overheating, and inconsistent clamping force by delivering:

-

Strong mechanical stability under vibration and thermal cycling.

-

High current capacity suitable for both control signals and heavy loads.

-

Versatile conductor compatibility that supports solid and stranded wires.

By combining these properties, screw terminal blocks meet the growing demand for both safety compliance and scalable performance in mission-critical projects.

Scaling for Modern Energy and Automation Projects

Unlike fixed wiring methods, screw terminal blocks allow systems to expand while keeping maintenance straightforward. This scalability is critical in projects that must grow with demand:

-

Renewable Energy Farms – Screw terminals ensure stable current transfer in solar inverters and wind turbine controllers, handling fluctuating loads without losing contact strength.

-

Automation Panels – In industrial control cabinets, screw blocks allow quick integration of new PLC modules or robotic units, avoiding full panel redesign.

-

HVAC and Building Systems – Energy-efficient buildings use screw connections to expand lighting, security, and climate control without interrupting ongoing operations.

-

Transportation Infrastructure – Railways and EV charging stations demand vibration-proof, long-life terminals to handle environmental stress.

Each environment places unique demands on wiring systems, and screw terminal blocks offer the adaptability to meet those challenges.

How Screw Terminal Blocks Compare in Performance

| Key Factor | Screw Terminal Blocks | Impact in Real Projects |

|---|---|---|

| Load Capacity | High current and voltage | Handles solar energy storage and industrial drives |

| Environmental Resistance | Stable under vibration and heat | Reliable in transport and renewable systems |

| Wiring Flexibility | Supports wide wire sizes | Simplifies mixed-signal and power wiring |

| Scalability | Easy to expand circuits | Enables phased industrial upgrades |

| Maintenance | Requires torque checks | Predictable, low-cost upkeep for large projects |

This shows why screw terminal blocks remain relevant even as new connector technologies emerge: they balance capacity, durability, and cost efficiency.

Addressing Real Buyer Concerns

Q1: How do screw terminal blocks improve uptime in automation systems?

By securing wires with torque-verified screws, they reduce failures caused by vibration or thermal expansion, ensuring continuous system operation.

Q2: Can screw terminals support renewable energy applications?

Yes. Their high current rating and reinforced insulation make them ideal for solar and wind applications where electrical stability is critical.

Q3: Are they globally compliant for export projects?

ZhongBo screw terminal blocks are tested to IEC, UL, and CE standards, ensuring acceptance in energy and automation projects worldwide.

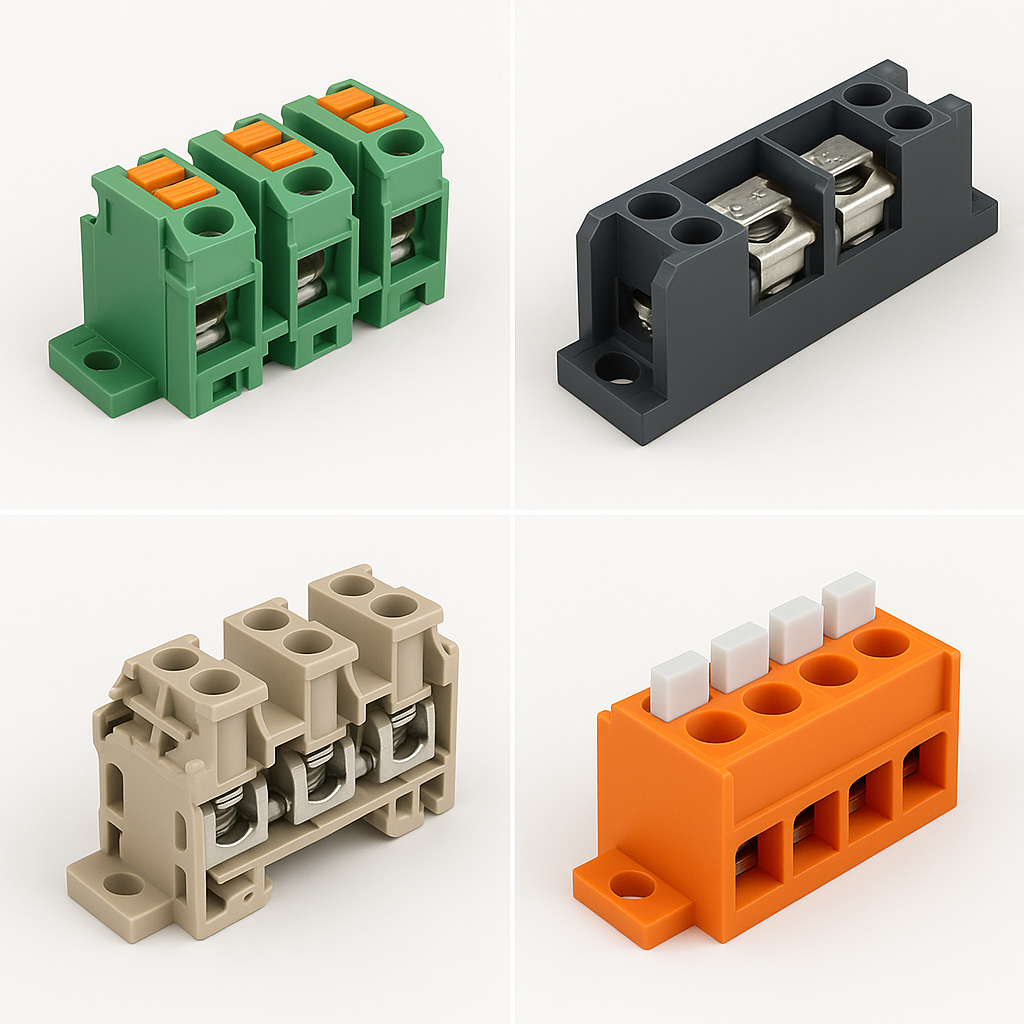

Why ZhongBo Screw Terminal Blocks Stand Out

At ZhongBo, screw terminal blocks are engineered with precision-threaded clamping screws, flame-retardant housings, and corrosion-resistant conductors. The factory integrates automated assembly lines and multi-step quality checks, covering:

-

Torque and contact resistance testing for every batch.

-

Thermal aging and vibration tests simulating harsh industrial environments.

-

OEM customization services to adapt screw terminals for different panel designs and environmental needs.

This commitment allows ZhongBo to support global projects with reliable supply, tailored configurations, and internationally recognized compliance.

For project-specific inquiries or detailed technical consultation, you can visit our homepage or reach us through our contact page.