Safe and Flexible Wiring: How Spring Clamp Terminal Blocks Meet Global Compliance Standards

Why Global Compliance Defines Modern Electrical Connections

In today’s energy and automation sectors, safety is more than just a technical requirement—it is a global obligation. Countries enforce IEC, UL, and CE standards to protect systems from overheating, fire risks, and downtime. For companies exporting equipment, failure to meet these benchmarks often means delayed approvals or rejected shipments.

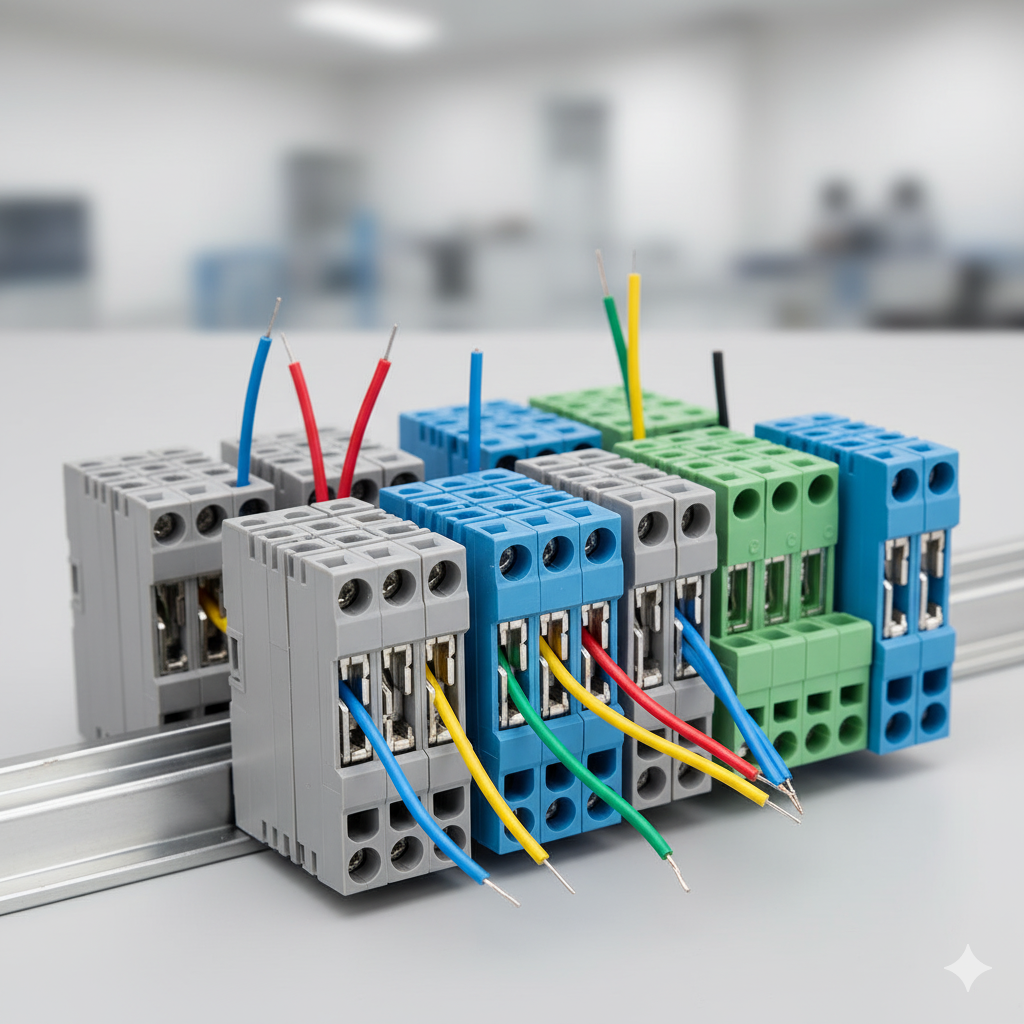

Spring clamp terminal blocks solve this challenge by integrating constant spring pressure, flame-retardant housings, and tested insulation resistance into every unit. Their compliance ensures that whether an installation is in Europe, North America, or Asia, the wiring is not only safe but also universally accepted.

How Spring Clamp Technology Translates Into Practical Safety

Traditional screw connections depend on torque accuracy, which can vary from operator to operator. In contrast, spring clamps maintain consistent force, preventing loosening under vibration or thermal expansion.

-

Reduced Installation Errors – Eliminates under- or over-tightening issues.

-

Improved Reliability in Harsh Conditions – Ideal for factories, transport systems, and outdoor renewable energy installations.

-

Fast Rework and Inspection – Tool-free connections reduce downtime during maintenance.

This makes spring clamps a preferred solution in compliance-driven industries, where even minor wiring errors can cause significant risks.

Industry Environments Where Compliance Meets Performance

Spring clamp terminal blocks prove their value across sectors that demand both flexibility and safety:

-

Renewable Energy – In solar and wind projects, they support high cycle loads and outdoor exposure, ensuring stable current transfer under fluctuating conditions.

-

Industrial Automation – Control cabinets and PLC systems benefit from fast, tool-free installation during large-scale wiring projects.

-

Commercial Buildings – HVAC, security, and lighting networks require certified wiring solutions that meet local and international safety codes.

-

Transport Infrastructure – Railways, EV chargers, and signaling equipment depend on vibration-proof wiring for long-term reliability.

-

Data Centers – High-density racks use spring clamps to reduce heat buildup and simplify upgrades, critical in environments where uptime is non-negotiable.

Each of these environments represents a compliance challenge—spring clamps make certification easier while delivering consistent field performance.

Comparing Spring Clamps with Traditional Wiring

| Feature | Spring Clamp Terminal Block | Screw Terminal Block |

|---|---|---|

| Installation Speed | Tool-free, fast, error-proof | Slower, torque-dependent |

| Vibration Resistance | Constant spring pressure | Requires regular torque checks |

| Compliance Readiness | Globally certified (IEC, UL, CE) | Certified but torque-sensitive |

| Maintenance | Minimal, quick rework | Periodic re-tightening |

| Application Fit | Ideal for control, automation, renewable | Better for very high current |

This comparison shows that while both types have their place, spring clamps offer a compliance-friendly and time-saving option for industries that need reliability without excessive maintenance.

Q&A

Q1: Are spring clamp terminals suitable for export projects?

Yes. With IEC, UL, and CE certifications, they can be integrated into systems bound for multiple international markets without additional approval steps.

Q2: How do they perform in high-vibration environments?

The spring mechanism ensures wires stay locked in place, making them ideal for railways, wind turbines, and heavy machinery.

Q3: Can they handle the same current as screw terminals?

For medium to high loads in automation and energy systems, yes. Screw terminals may still be preferred for extreme high-current distribution, but spring clamps cover most modern control and distribution needs effectively.

Why ZhongBo Is the Right Manufacturing Partner

At ZhongBo, spring clamp terminal blocks are not just manufactured for compliance—they are engineered for real-world reliability. Our processes include:

-

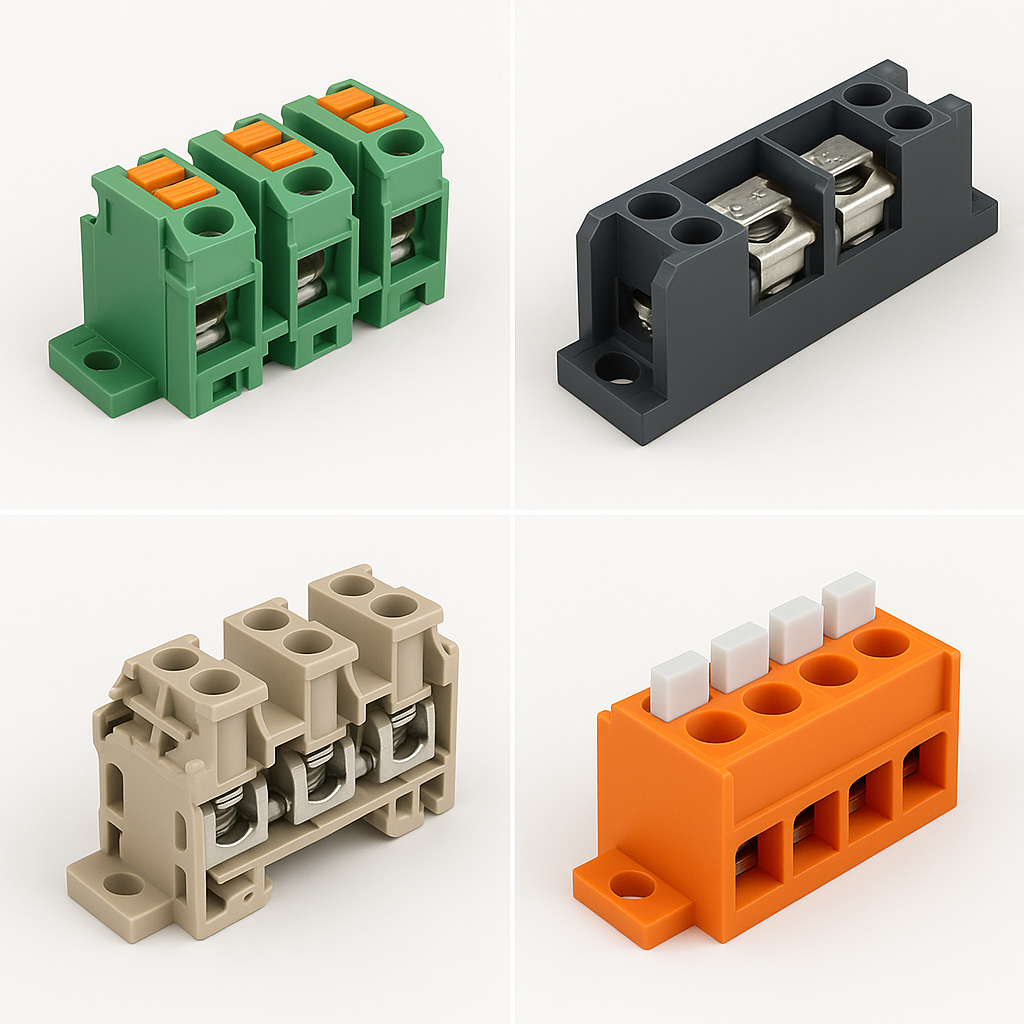

CNC precision forming of spring components for consistent clamping force.

-

Automated testing for insulation resistance, heat cycles, and mechanical stress.

-

OEM customization for housing materials, terminal pitch, and modular designs.

-

Global certifications (IEC, UL, CE) to guarantee acceptance in international projects.

By combining compliance with practical design features, ZhongBo ensures that customers achieve safe, flexible, and globally recognized wiring solutions.

To explore our solutions in detail, visit our homepage or connect directly through our contact page.