Lighting Stability Starts Here: Engineering PCB Terminal Blocks for LED Drivers

Every LED driver tells the same story: constant current, limited space, and continuous heat.

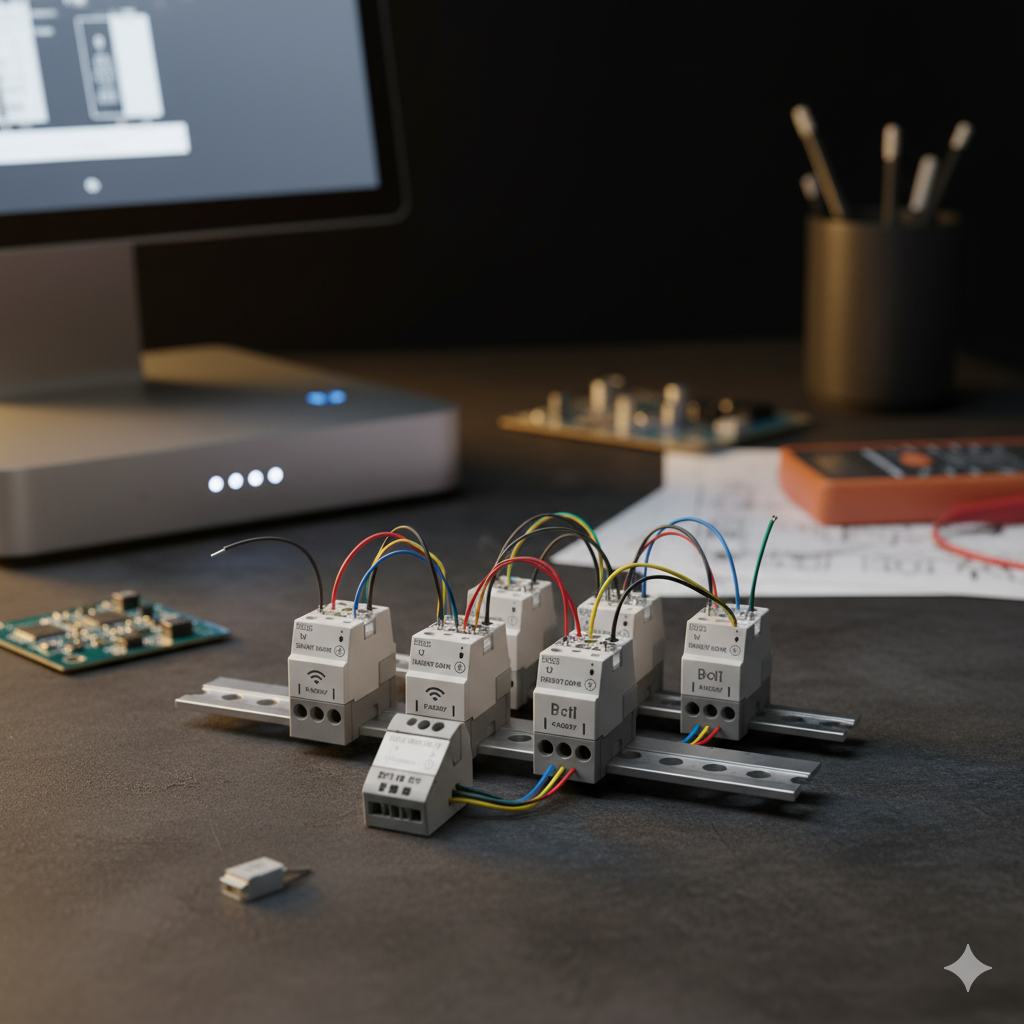

Behind the flawless glow of a lighting fixture is a small but critical component — the PCB terminal block for LED driver — responsible for maintaining stable electrical flow between the driver, circuit board, and light source.

In lighting electronics, even a minor fluctuation or poor connection can shorten lifespan, distort output, or trigger overheating.

That’s why terminal blocks have evolved from simple wire holders into precision-engineered power interfaces designed for durability and thermal stability.

Why LED Drivers Demand Specialized Terminal Blocks

LED drivers operate under high-frequency switching and constant thermal cycling.

Their internal components — capacitors, inductors, and ICs — generate heat that continuously stresses the PCB.

Using general-purpose connectors in this context can lead to:

-

Loosened wires from vibration or expansion

-

Contact oxidation reducing current flow

-

Cracked insulation after prolonged heat exposure

To counter these risks, LED-specific terminal blocks feature:

-

Compact low-profile design for slim driver housings

-

High-temperature resistant materials (PA66 or LCP UL94 V-0)

-

Reflow soldering compatibility for automated assembly lines

-

Gold- or tin-plated contacts for consistent conductivity over time

These upgrades turn what was once a weak link into one of the most reliable points in the LED power circuit.

Material Engineering Behind Long-Life LED Connections

| Component | Preferred Material | Function |

|---|---|---|

| Housing | PA66 or LCP UL94 V-0 | Flame-retardant and thermally stable |

| Contact Pin | Copper alloy, tin/nickel plated | Low resistance and anti-oxidation |

| Clamping System | Spring or push-in clamp | Easy installation, no re-torque needed |

| Base Type | SMT or THR compatible | Supports automatic reflow processes |

Each part of the connector is tested under thermal shock (−40°C to +125°C) and dielectric strength ≥2.0kV, ensuring performance even in compact LED housings with minimal airflow.

From Traditional Connectors to Modern Lighting Interfaces

| Feature | Standard PCB Connector | LED Driver Terminal Block |

|---|---|---|

| Operating Temperature | Up to 85°C | Up to 125°C |

| Pitch Size | 5.08 mm typical | 3.5 mm / 2.5 mm compact pitch |

| Mounting | Through-hole only | SMT + push-in reflow safe |

| Service Life | Limited insertions | 100+ insertion cycles |

| Power Range | General low-voltage | Optimized for 12V–48V LED drivers |

This new generation of PCB terminal blocks combines space efficiency and thermal durability, fitting perfectly into linear LED drivers, power supply modules, and smart lighting controls.

Applications Across LED Power and Control Systems

| Application | Electrical Role | Recommended Type |

|---|---|---|

| LED Driver Board | Power input/output | 3.5 mm pitch pluggable block |

| Smart Lighting Control Unit | Signal wiring | Low-current spring clamp |

| Street Lighting Power Module | High current connection | 7.62 mm barrier block |

| Architectural Lighting Panels | Compact PCB interface | SMT terminal block |

| Emergency Lighting Power Supply | Heat-resistant design | LCP housing terminal |

Each scenario demands consistent current flow, compact form factors, and zero maintenance — areas where precision terminal blocks outperform conventional connectors.

Engineering Guidelines for Lighting System Designers

When choosing terminal blocks for LED applications, small design decisions make a big difference:

-

Choose pitch spacing (2.5–3.81 mm) according to PCB layout density.

-

Verify UL, CE, and RoHS compliance for global lighting certifications.

-

Prefer spring clamp systems for vibration-prone fixtures like street lights.

-

Use nickel- or gold-plated contacts to prevent oxidation in humid environments.

-

Confirm reflow soldering compatibility for automated LED driver assembly.

Following these engineering practices ensures stable brightness, safer operation, and longer system lifespan.

Common Questions from LED System Engineers

Q1: Why are LED drivers sensitive to connector quality?

A: Because any small resistance increase or loose contact directly affects current balance, resulting in flickering or heat buildup.

Q2: Can LED terminal blocks handle high ambient temperatures?

A: Yes. LCP or PA66 housings are designed to withstand up to 125°C continuous operation.

Q3: Are reflow-compatible terminals necessary for LED PCBs?

A: Absolutely. They enable fully automated assembly and improve production consistency.

Q4: What certifications should lighting OEMs look for?

A: UL1059, IEC 60947-7-1, and RoHS compliance are the standard benchmarks for export.

luminating the Future with Smarter Electrical Design

In modern lighting, efficiency isn’t just about lumens per watt — it’s about connection quality per circuit.

A well-designed PCB terminal block for LED driver ensures stable power delivery, lower maintenance, and longer LED lifespan, forming the unseen foundation of every reliable lighting system.

Zhongbo continues to support lighting manufacturers worldwide with compact, heat-resistant PCB terminal blocks designed for LED drivers and power electronics.

For OEM collaboration or technical consultation, visit our homepage or contact us.