Power You Can Trust: How Terminal Blocks Streamline Electrical Distribution

Every electrical system, from factory switchboards to building power panels, relies on one shared truth — stable connections mean reliable power.

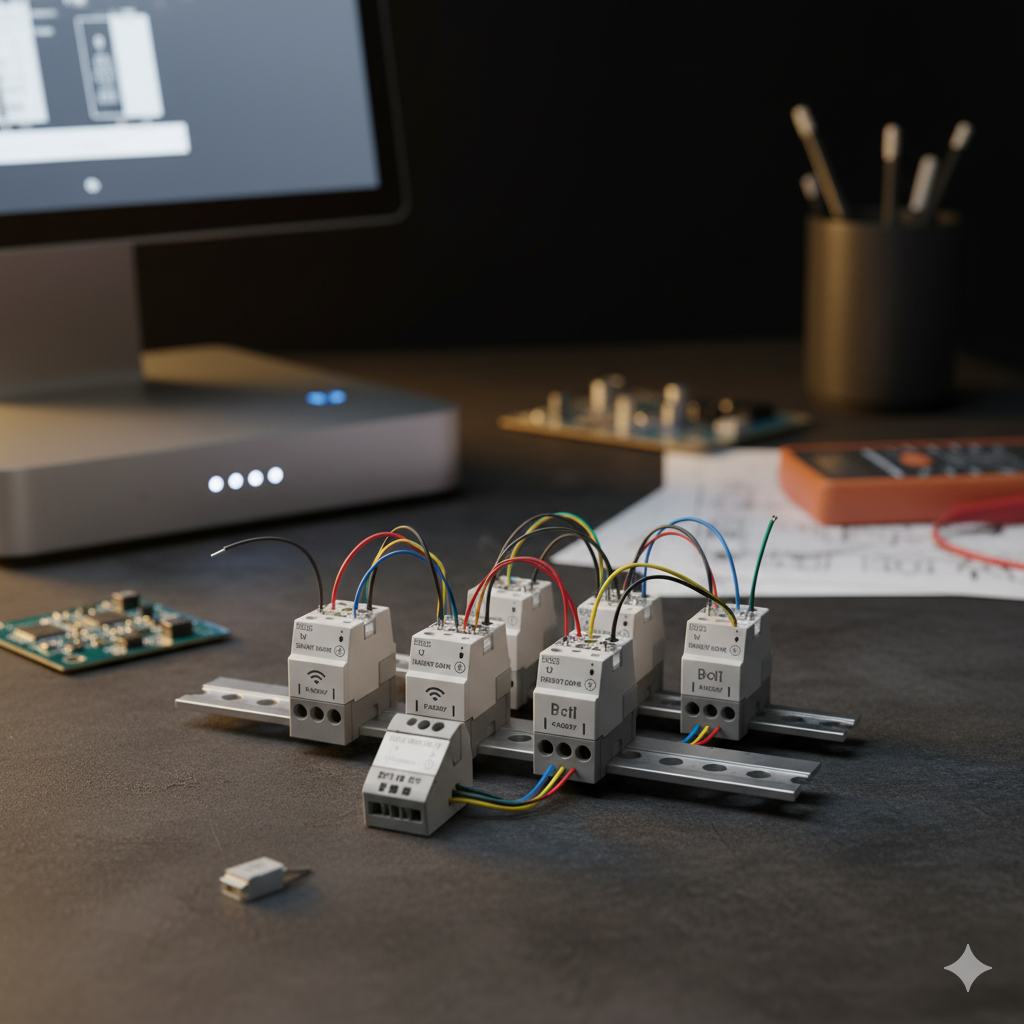

At the heart of that stability lies an often-overlooked component: the terminal block for power distribution.

Designed to carry high currents safely and efficiently, these connectors ensure that every load — motors, sensors, or lighting systems — receives consistent power. They are the bridge between heavy-duty energy and the delicate control logic that keeps everything running smoothly.

Why Distribution Systems Depend on Quality Terminal Blocks

In a power distribution network, terminals are more than just mechanical joints. They’re electrical control points, responsible for transferring current, preventing arcing, and maintaining system balance.

Poorly designed connections can lead to:

-

Voltage drops that waste energy and reduce efficiency.

-

Overheating due to inconsistent contact pressure.

-

Maintenance risks, where loose wires cause downtime or hazards.

Engineered terminal blocks eliminate these problems with optimized contact geometry, flame-retardant housings, and corrosion-resistant materials that guarantee years of stable performance.

Engineering Materials That Keep Power Flowing

Power distribution systems demand both mechanical endurance and electrical precision. Every material inside a terminal block serves a purpose.

| Component | Material | Function |

|---|---|---|

| Housing | PA66 UL94 V-0 | Flame-retardant and thermally stable insulation |

| Conductors | Copper or brass (nickel/tin plated) | High conductivity and oxidation resistance |

| Clamping Mechanism | Steel or copper alloy | Maintains constant torque under vibration |

| Mounting Type | DIN rail / panel mount | Easy installation and modular expansion |

Together, these materials create connectors that handle currents from 20A to over 200A, ensuring that even under full load, the temperature rise stays within safety limits.

Traditional Busbars vs. Modular Terminal Blocks

| Criteria | Traditional Busbar | Modular Power Terminal Block |

|---|---|---|

| Installation | Fixed structure, manual wiring | Tool-free modular assembly |

| Maintenance | Complex disassembly | Individual pole access for service |

| Safety | Open conductive paths | Fully insulated housings |

| Scalability | Limited expansion | Add or remove modules easily |

| Application | Heavy electrical rooms | Distributed industrial panels |

While busbars remain common in legacy systems, modular terminal blocks are increasingly preferred in smart factories, building automation, and renewable energy systems for their combination of safety, flexibility, and serviceability.

Applications Across Industrial Power Networks

| Application Area | Electrical Role | Recommended Terminal Type |

|---|---|---|

| Main Power Panels | Incoming and outgoing feeds | High-current screw terminal block |

| Motor Control Centers | Load distribution | Barrier or feed-through type |

| Lighting Power Systems | Branch circuit wiring | Compact modular terminal |

| Renewable Energy Inverters | DC/AC transfer | 1000V-rated pluggable terminal |

| Commercial Buildings | Panel interconnections | DIN-rail modular type |

In each of these environments, terminals must maintain low resistance under constant load, often in conditions with heat, dust, or vibration.

Practical Design Tips for Electrical Engineers

Designing an efficient power distribution panel isn’t only about current capacity — it’s about safety, organization, and future maintenance.

Here’s what professional engineers prioritize when choosing terminal blocks:

-

Select current ratings ≥125% of expected load to prevent heat buildup.

-

Ensure contact pressure consistency through screw or spring clamp mechanisms.

-

Use color-coded terminals to separate phases (L1/L2/L3) and grounding.

-

Maintain minimum creepage distances per IEC 60664-1 for high voltage applications.

-

Prefer DIN-rail modular designs for quick expansion or replacement.

A well-designed connection system saves not only wiring time but also hours of troubleshooting in the field.

Common Questions from Power System Designers

Q1: How much current can a typical terminal block handle?

A: Depending on size and conductor type, most industrial models support 20A–200A continuous current.

Q2: What prevents overheating in power terminals?

A: Tight contact geometry, high-conductivity copper alloys, and optimized air spacing reduce thermal rise.

Q3: Can terminal blocks replace busbars entirely?

A: For modular and medium-current systems, yes. Busbars remain useful for heavy load centers.

Q4: Are these terminals suitable for DC systems?

A: Absolutely. Many models are rated up to 1000V DC for solar, storage, or EV applications.

Building Safer Power Networks Through Smarter Connections

Every electrical panel tells a story of balance — between current and heat, power and precision, performance and safety.

Modern terminal blocks for power distribution are designed to uphold that balance, offering engineers a scalable, reliable, and maintenance-friendly foundation for any industrial or commercial project.

Zhongbo continues to support global power system integrators with high-current terminal blocks engineered for safe energy distribution, certified under UL1059 and IEC 60947-7 standards.

For OEM partnerships or technical specifications, visit our homepage or contact us.