Engineering Safety Standards: How UL Terminal Blocks Ensure Reliable Power Connections in the U.S.

In the United States, compliance isn’t optional — it’s the foundation of trust.

Every electrical product entering the U.S. market must meet rigorous safety and performance benchmarks defined by Underwriters Laboratories (UL).

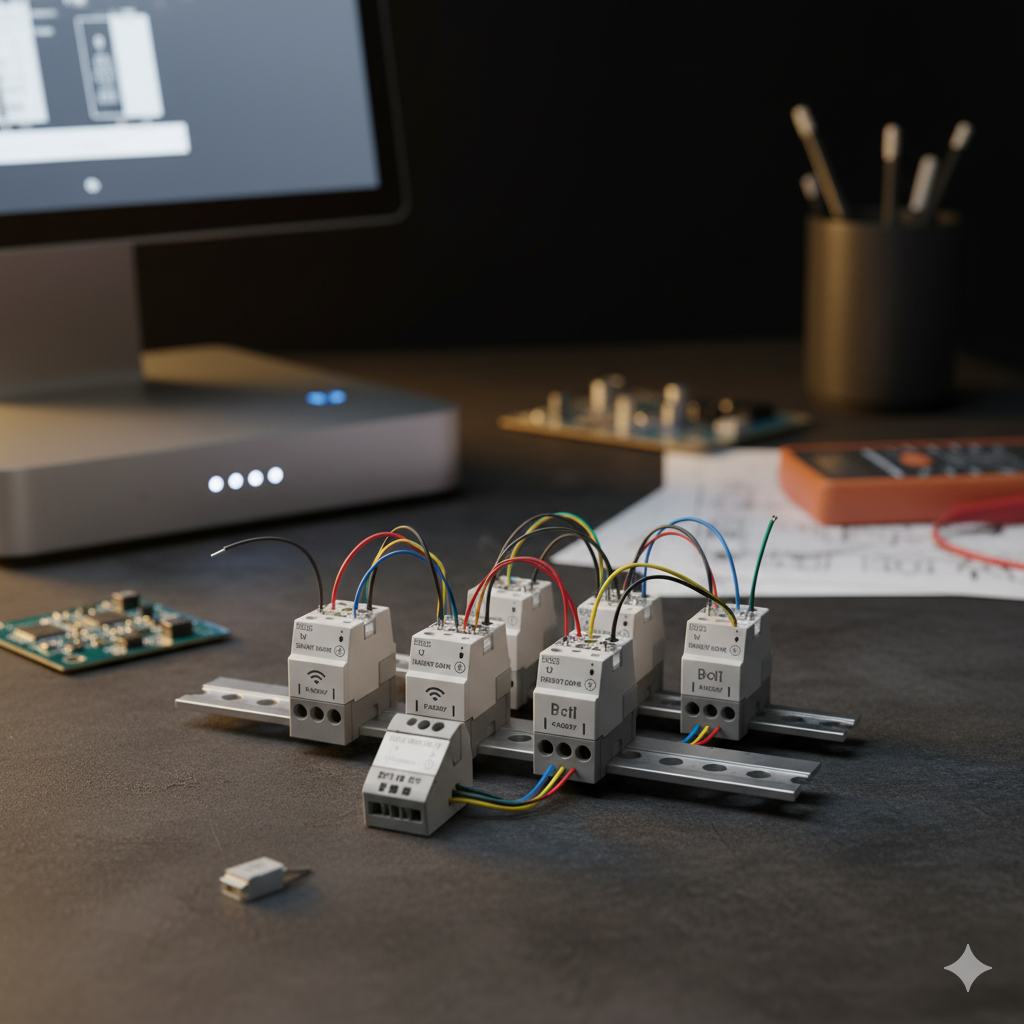

For terminal blocks — the backbone of power distribution and control wiring — UL certification is more than a label. It’s a declaration that every connection, from the smallest PLC circuit to high-current bus systems, has been tested for thermal endurance, dielectric strength, and mechanical integrity under North American standards.

The Role of UL Certification in Industrial Connectivity

UL standards were established to ensure that electrical components can safely handle their rated loads without risk of fire, arcing, or material breakdown.

For terminal blocks, the key benchmark is UL1059, which outlines testing for:

-

Insulation resistance and dielectric strength under overload

-

Temperature rise at rated current

-

Wire retention and mechanical pull-out force

-

Flammability ratings for housing materials

-

Marking and identification requirements

When a component carries the UL mark, it means it has been independently verified to meet these standards, giving manufacturers and OEM engineers confidence that the product complies with both UL and CSA (Canadian Standards Association) norms for North America.

Material and Structural Design Behind UL Terminal Blocks

UL compliance starts from the inside — with material science and engineering discipline.

| Component | Typical Material | Compliance Purpose |

|---|---|---|

| Housing | PA66 UL94 V-0 | Flame-retardant and self-extinguishing |

| Conductor | Tin-plated brass / copper alloy | Maintains conductivity under high load |

| Clamping Type | Screw or spring clamp | Prevents loosening from vibration |

| Terminal Marking | Laser-etched UL number | Traceable compliance verification |

The UL94 V-0 rating is particularly critical: it ensures the plastic housing self-extinguishes within 10 seconds after ignition, preventing flame propagation — a core requirement for control panels and power modules in the U.S.

General Terminal Blocks vs. UL-Certified Models

| Feature | General Terminal Block | UL-Certified Terminal Block |

|---|---|---|

| Testing Standard | Manufacturer self-evaluation | Independent UL lab testing |

| Temperature Rise Control | Not guaranteed | Verified per UL1059 |

| Fire Resistance | Basic insulation | UL94 V-0 or better |

| Marking and Traceability | Optional | Mandatory UL file number |

| Acceptance in U.S. Market | Limited | Fully approved and preferred |

For electrical OEMs exporting to North America, the difference isn’t just technical — it’s commercial. Non-certified terminals often fail inspection, causing project delays, rework costs, or rejection by local authorities.

Applications Where UL Terminal Blocks Are Mandatory

UL-certified terminal blocks are used wherever safety compliance and liability control are non-negotiable:

-

Industrial control cabinets (UL508A certified panels)

-

HVAC and building automation systems

-

Renewable energy systems (UL1741)

-

Transportation and EV charging stations

-

Lighting and power distribution units

In the U.S., panel builders and system integrators must use components that carry matching UL ratings to maintain certification for the entire assembly. That’s why engineers specify UL-approved terminals from the start — it simplifies audits and ensures long-term reliability.

Application Recommendations: Selecting the Right UL Terminal Block for Different Systems

Choosing the correct UL terminal block depends on your system’s current level, environment, and wiring structure.

Here are a few common application-based suggestions:

-

For control and automation panels → use screw-type or spring-clamp UL1059 Class C terminals, ideal for multi-point PLC and relay wiring.

-

For HVAC and building systems → select pluggable or modular types, allowing quick replacement during field maintenance.

-

For solar and energy storage units → use high-voltage UL-rated terminals (up to 1000V) with anti-tracking materials to prevent surface leakage.

-

For lighting and compact devices → choose miniature UL-certified connectors with low profile and quick installation design.

-

For industrial power distribution → opt for barrier or feed-through terminal blocks, supporting higher current loads up to 150A.

By aligning your product selection with application demands, you can ensure both compliance and efficiency, avoiding costly redesigns during final UL panel inspections.

Frequently Asked Questions

Q1: Are UL terminal blocks required for all U.S. exports?

A: For most industrial or commercial systems, yes — especially panels under UL508A or UL845 classifications.

Q2: Can CE-certified terminals replace UL ones?

A: No. CE marks indicate conformity for the EU market but don’t guarantee acceptance in North America.

Q3: What is the difference between UL Recognized and UL Listed?

A: UL Recognized components are for integration inside systems, while UL Listed products are complete, standalone devices.

Q4: How often must UL certifications be renewed?

A: UL requires periodic factory inspections to verify ongoing compliance — typically twice per year.

Engineering Compliance Into Every Connection

Safety and reliability aren’t optional — they’re fundamental expectations in the U.S. market.

Using UL terminal blocks ensures every connection meets national standards, protecting both systems and reputations.

Zhongbo continues to provide UL1059-certified terminal blocks tailored for industrial control, automation, and power systems, ensuring seamless compliance with North American standards.

For technical consultation or UL documentation requests, visit our homepage or contact us.