Ensuring European Compliance: How CE Terminal Blocks Support Safe Electrical Connections

In the European Union, electrical safety and certification are the foundation of trust between manufacturers, importers, and end users.

Every component, from industrial relays to control terminals, must comply with the CE (Conformité Européenne) mark — proof that it meets essential EU directives for safety, performance, and environmental protection.

For global suppliers and European buyers, CE terminal blocks are not just compliant parts — they are the link that ensures each circuit operates safely within the EU’s harmonized technical framework.

The CE Certification Framework and Its Importance

The CE mark indicates that a product complies with the Low Voltage Directive (LVD 2014/35/EU), RoHS, and Machinery Directive (2006/42/EC) — core standards governing electrical safety in the EU market.

For terminal blocks, this certification covers:

-

Insulation reliability and dielectric strength under load

-

Temperature endurance for continuous operation

-

Fire-retardant and halogen-free materials

-

Mechanical stability for vibration and pull-out tests

-

Environmental compliance (RoHS/REACH) for restricted substances

Without CE marking, imported electrical components cannot be legally sold or installed within EU member states — making compliance the first step to market entry.

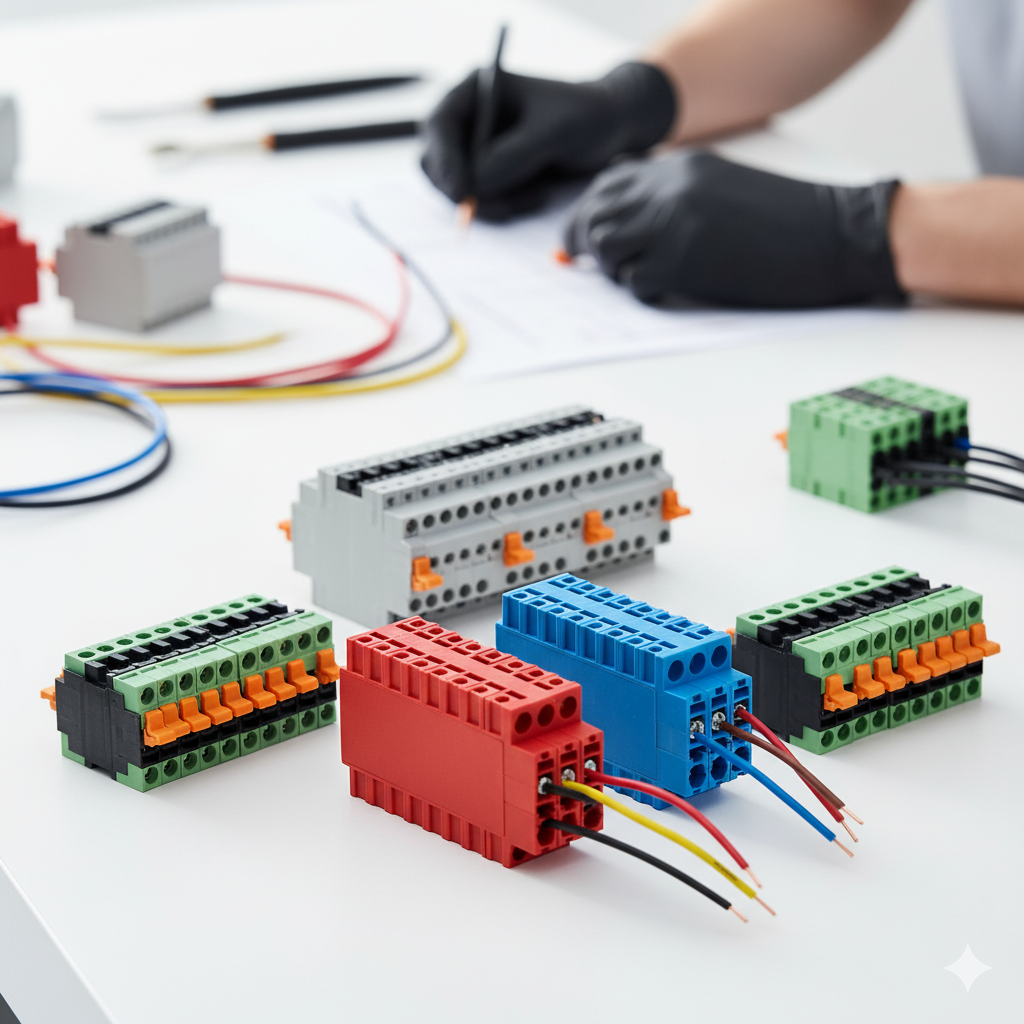

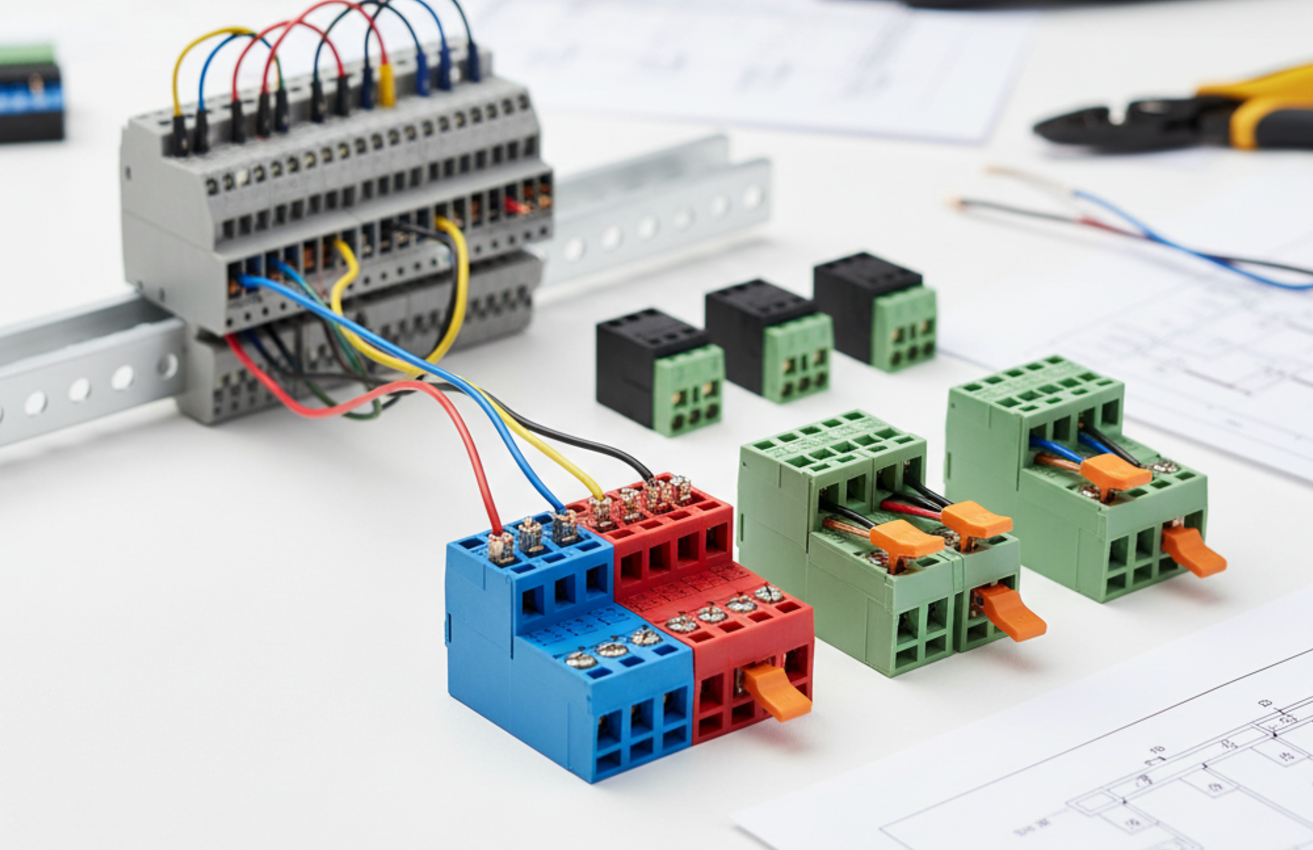

Engineering Design Behind CE-Compliant Terminal Blocks

European buyers prioritize performance stability, safety, and standardization. CE-certified terminal blocks are built around these key design elements:

| Design Aspect | Technical Standard | Function |

|---|---|---|

| Housing Material | PA66 / PBT, UL94 V-0 | Flame-retardant and durable |

| Conductor Material | Tin-plated brass / copper alloy | High conductivity, corrosion resistance |

| Voltage Rating | 300V–1000V | Compliant with IEC60947-7-1 |

| Pitch Options | 2.5–10.16mm | Compatible with EU control systems |

| Temperature Range | -40°C to +125°C | Industrial-grade operation |

| Testing Standard | IEC 60998 / EN 60947 | EU-approved safety benchmark |

These parameters ensure that CE terminal blocks are not only safe but also interoperable across European automation, energy, and building systems.

CE Terminal Blocks vs. Non-Certified Products

| Category | CE Terminal Block | Non-Certified Product |

|---|---|---|

| Compliance | Meets EU Directives | Fails LVD and RoHS requirements |

| Market Access | Approved for EU import | May be rejected or fined |

| Material Traceability | Documented via CE files | Unverified |

| Electrical Reliability | Tested under IEC standards | Inconsistent performance |

| Buyer Confidence | Recognized by EU authorities | High risk of non-acceptance |

For European importers and distributors, choosing CE-certified components ensures smooth customs clearance, legal compliance, and reduced liability for downstream installations.

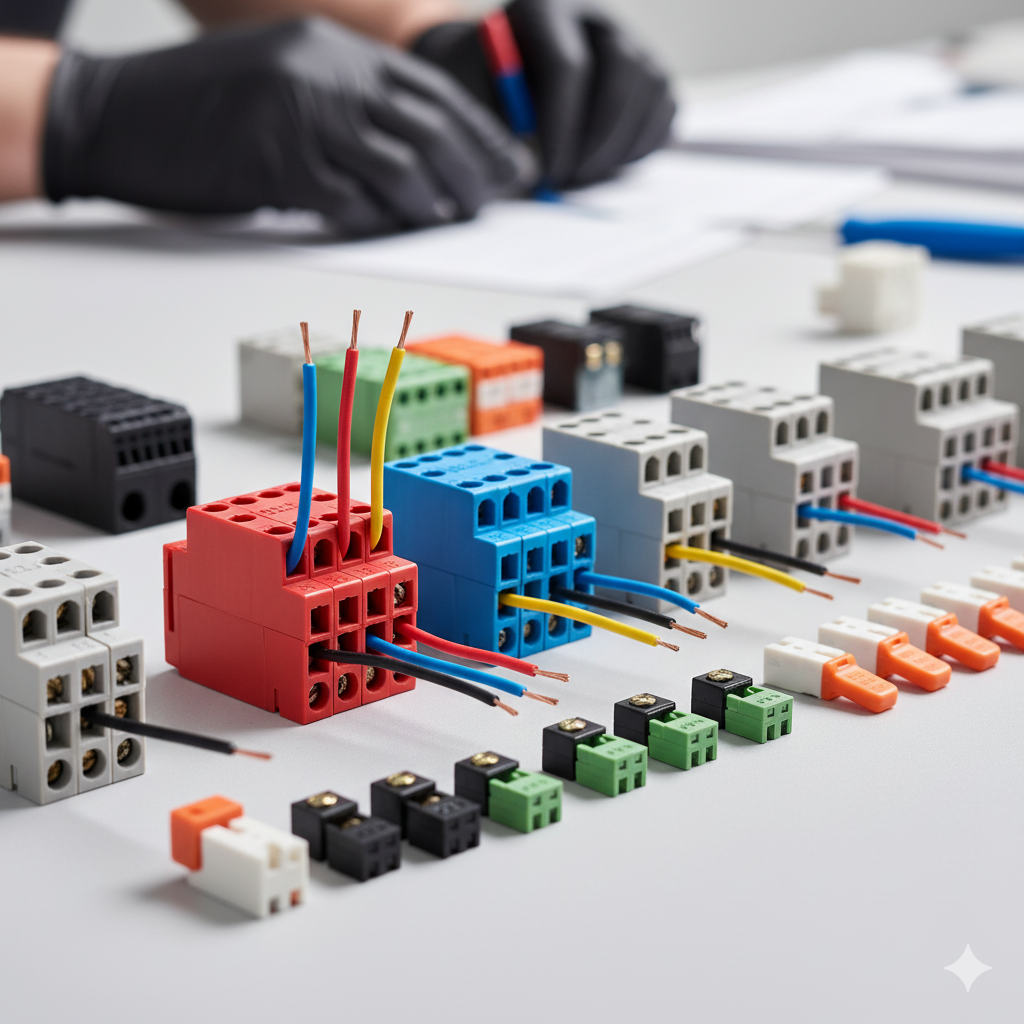

Selecting the Right CE Terminal Block Based on Application and Environment

European industries vary widely — from precision automation to renewable energy — and each requires specific terminal block configurations. Below are key recommendations for selecting the right model:

-

For industrial control and factory automation

Use screw or spring-cage terminals certified under IEC60947-7-1. These ensure vibration resistance and secure current transfer, ideal for PLC wiring and distributed I/O systems. -

For energy and renewable systems

Choose high-voltage CE terminal blocks (up to 1000V DC) with reinforced insulation and anti-tracking materials to handle solar inverter and battery cabinet applications. -

For HVAC and building automation

Opt for modular pluggable terminals that allow easy maintenance and reconfiguration in building control systems, reducing wiring downtime. -

For lighting and consumer electronics

Select miniature CE-certified terminals with narrow pitch spacing (2.54–5.08mm) designed for compact driver or power adapter enclosures. -

For transportation and marine environments

Consider corrosion-resistant terminals with nickel-plated metals and flame-retardant housings to ensure reliability under humidity and vibration.

Matching the correct CE terminal block to your application not only improves system safety but also simplifies documentation and approval during EU inspections.

Frequently Asked Questions

Q1: What standards define CE compliance for terminal blocks?

A: Key references include IEC60947-7-1, EN60998, and the Low Voltage Directive (2014/35/EU).

Q2: Are CE and UL certifications equivalent?

A: No. CE applies to the EU market under its directives, while UL covers North American safety standards.

Q3: Can a single product be both UL and CE certified?

A: Yes. Many global suppliers, including Chinese manufacturers, obtain both marks to serve multi-region exports.

Q4: How can EU buyers verify a supplier’s CE compliance?

A: Request the Declaration of Conformity (DoC) and supporting test reports issued by authorized laboratories.

Building Trust Through Certified Connections

In Europe’s safety-driven electrical market, compliance is not optional — it’s the entry ticket.

CE-certified terminal blocks protect not only electrical systems but also the business reputation of every importer and integrator.

Zhongbo continues to supply CE-compliant terminal blocks for industrial, automation, and renewable sectors, helping European buyers achieve reliable connectivity and full regulatory compliance.

For detailed specifications or CE documentation, visit our homepage or contact us.