Global Standards, Local Strength: How Chinese Terminal Block Manufacturers Lead in Export Quality

In today’s interconnected manufacturing world, electrical safety and consistency transcend borders.

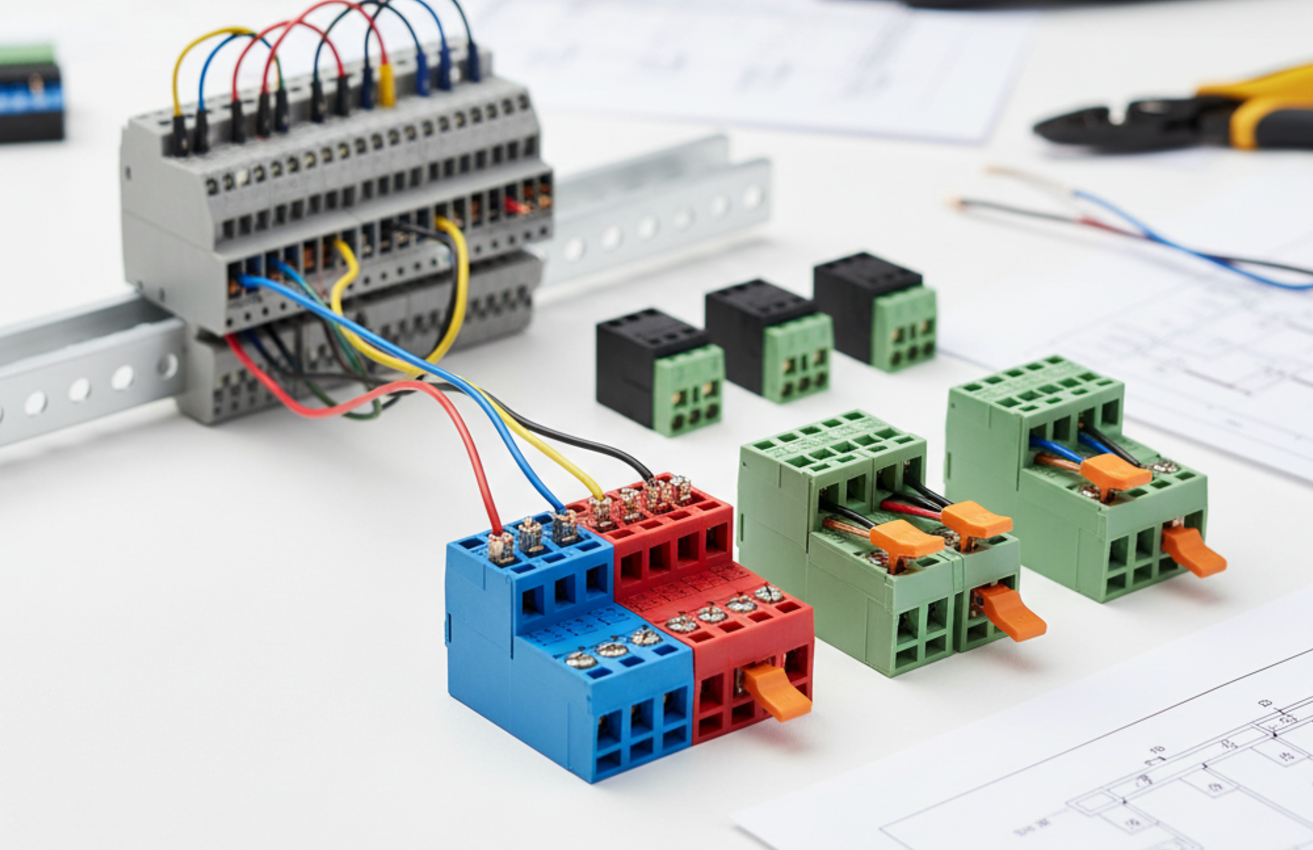

From industrial control panels in Germany to solar farms in Brazil, engineers rely on dependable terminal blocks to ensure power integrity and stable signal flow.

Over the past decade, China has emerged as a global export hub for terminal blocks — not just for cost advantages, but for its growing capability to produce certified, export-grade components that meet UL, CE, and IEC standards.

From Local Workshop to Global Supply Network

Chinese terminal block manufacturers have undergone a remarkable transformation.

What began as small-scale metalworking shops has evolved into automated, quality-controlled facilities supplying OEM and ODM clients worldwide.

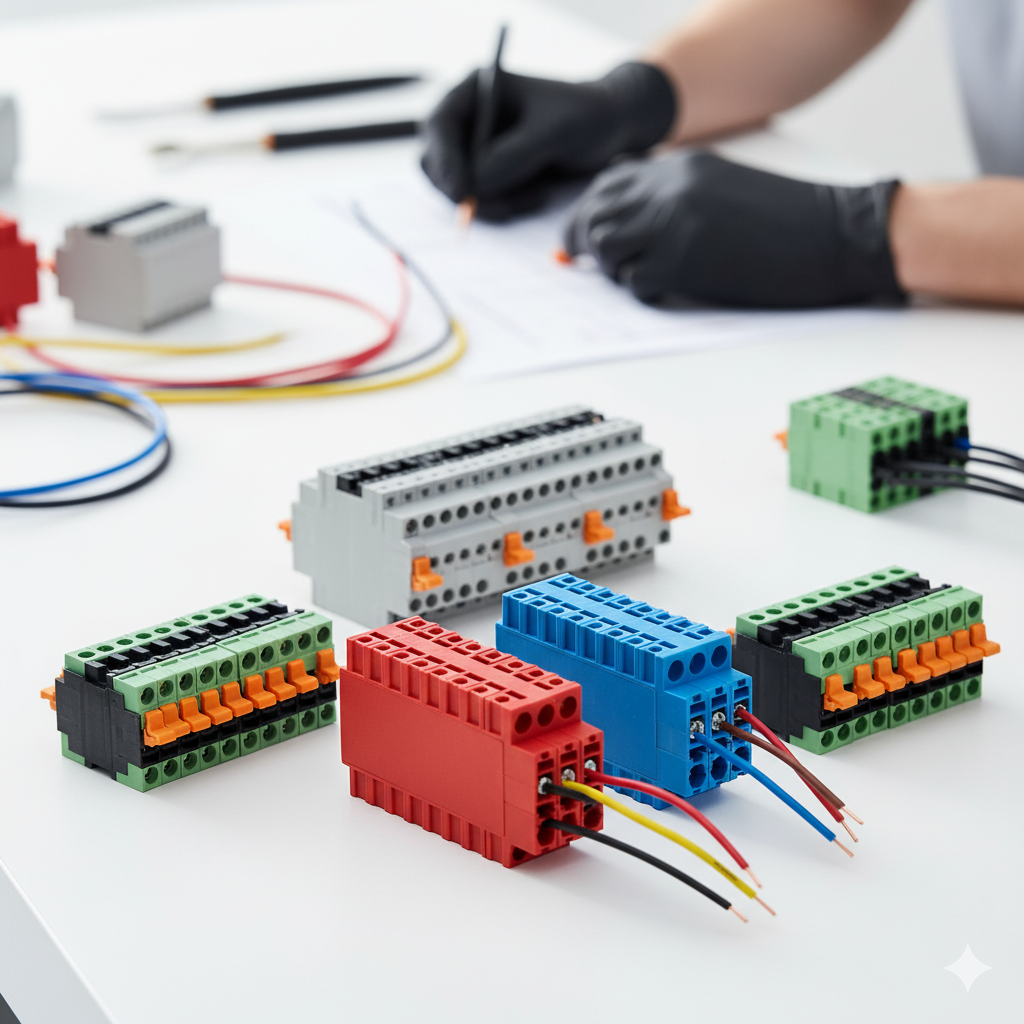

Today’s leading factories integrate:

-

Automated injection molding and metal stamping lines for consistency

-

Digital inspection systems for torque and conductivity testing

-

ERP-based production traceability from raw materials to packaging

-

In-house R&D for customized plug-in, spring clamp, and barrier terminal series

This shift allows Chinese manufacturers to meet export clients’ requirements for volume reliability, customization flexibility, and fast logistics.

Engineering Standards That Define Export Quality

The global competitiveness of Chinese terminal block exports lies in standardization and testing.

| Parameter | Export-Grade Specification | International Benchmark |

|---|---|---|

| Insulation Housing | UL94 V-0 rated PA66 / PBT | UL & IEC compliant |

| Conductor Material | Nickel-plated brass / copper alloy | RoHS & REACH certified |

| Voltage / Current Rating | 300V–1000V / up to 150A | UL1059 / IEC60947 |

| Pitch Options | 2.54–10.16mm | Global PCB compatibility |

| Temperature Range | -40°C to +125°C | Industrial-grade stability |

With these controlled parameters, exported terminal blocks from China maintain performance in harsh or high-load environments, enabling safe operation across automation, energy, and HVAC systems.

How Chinese Export Manufacturers Compete Globally

| Capability | China Manufacturers | Global Competitors |

|---|---|---|

| Manufacturing Speed | Automated lines, 20–30% faster | Manual-intensive |

| Customization | High, supports OEM / ODM | Often limited |

| Certification Coverage | UL, CE, TUV, ISO9001 | Region-specific |

| Supply Scale | 100k–500k pcs/day | Small-batch focused |

| Pricing Structure | Optimized labor + tooling cost | Higher overheads |

Rather than competing on price alone, modern Chinese suppliers focus on engineering partnerships — providing design support, CAD models, and quick sampling for international clients.

This approach bridges the traditional gap between affordability and technical reliability.

Industry Applications Driving Export Demand

Chinese terminal block exports now serve diversified industries worldwide:

-

Automation & control systems: PLC panels, relays, and I/O modules

-

Renewable energy: 1000V solar combiner boxes, battery packs, and inverters

-

HVAC and appliances: wiring harnesses, temperature controllers, and sensors

-

Lighting systems: LED driver modules and power adapters

-

Transportation & EVs: charging interfaces and onboard DC converters

The demand for modular, high-density, and pluggable terminal designs continues to grow as global industries digitalize their power infrastructure.

Choosing the Right Export Partner in China

When sourcing from a Chinese terminal block manufacturer, selecting the right partner can make or break a project.

Key factors to consider include:

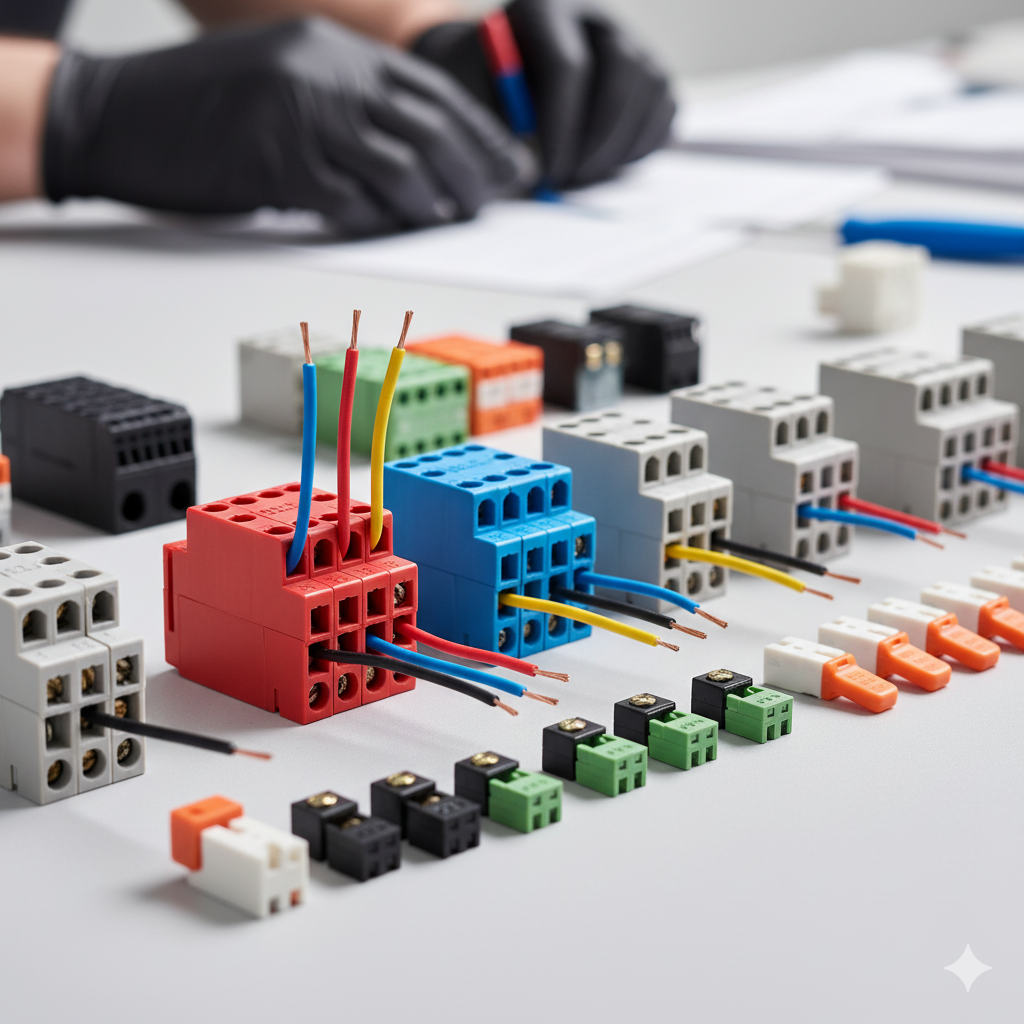

-

Certification Transparency — UL, CE, or TUV documents should be verifiable.

-

Material Consistency — use of virgin PA66, PBT, or PC for long-term heat resistance.

-

Sample Validation — testing torque, insulation, and conductivity before volume order.

-

OEM/ODM Support — ability to customize housing color, pitch, and marking.

-

Global Logistics — factory proximity to ports such as Ningbo, Shanghai, or Shenzhen for efficient shipping.

Reliable suppliers not only provide stable product quality but also deliver engineering documentation, 3D models, and test reports for smooth integration into global production lines.

Frequently Asked Questions

Q1: Do Chinese terminal block manufacturers offer UL or CE certification?

A: Yes. Leading suppliers hold both UL1059 and CE certifications for export compliance.

Q2: Can they support custom color, pitch, or packaging for branding?

A: Absolutely. Most factories provide OEM/ODM services with full customization options.

Q3: How long is the typical export lead time?

A: Around 15–25 working days for standard models; 30–45 days for customized tooling.

Q4: Are Chinese terminals compatible with Western wiring standards?

A: Yes. They comply with IEC and UL dimensions, fitting control panels across North America and Europe.

Shaping Global Reliability Through Chinese Manufacturing

China’s evolution from low-cost supplier to trusted engineering manufacturer has redefined the global terminal block industry.

By combining precision tooling, certified materials, and agile production, Chinese suppliers deliver products that meet — and often exceed — international expectations.

Zhongbo continues to export high-performance terminal blocks to global automation, HVAC, and renewable sectors, ensuring every connection reflects both safety and reliability.

For partnership inquiries or export specifications, visit our homepage or contact us.