Building Global Connectivity: Inside China’s Leading Terminal Block Suppliers

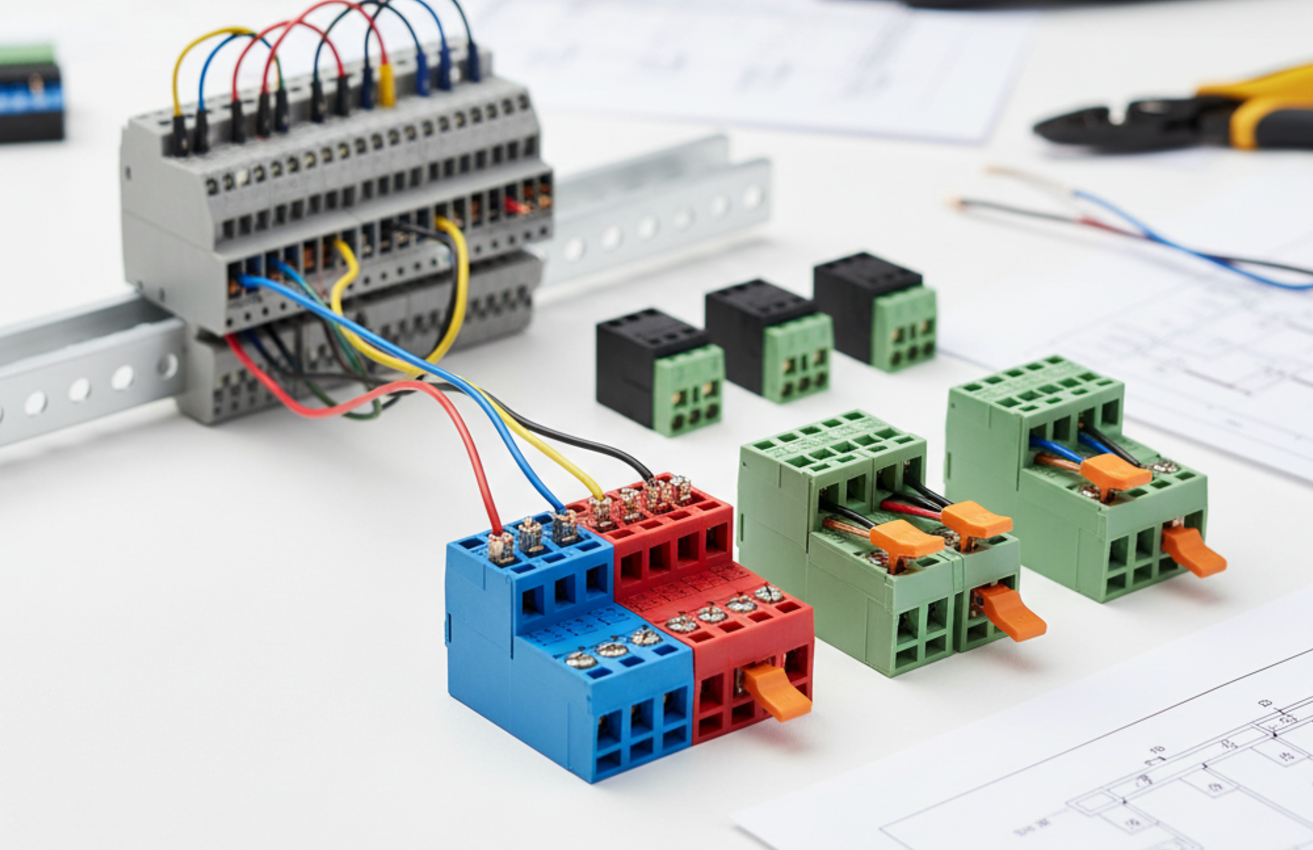

In global manufacturing, electrical connectivity defines reliability.

From industrial automation to renewable energy systems, every circuit depends on the strength of its terminal connections. As industries expand globally, sourcing from a terminal block supplier in China offers not just cost benefits but also engineering depth and scalability that match international standards.

Why China Leads the Global Terminal Block Industry

China’s rise in terminal block manufacturing is driven by three key factors — precision engineering, scale, and certification.

Over the last decade, the country has built a mature ecosystem of suppliers integrating mold design, material formulation, and automated assembly lines.

Modern facilities in regions like Zhejiang, Jiangsu, and Guangdong specialize in:

-

High-current and PCB terminal blocks for power and control systems

-

Spring-cage and screw-type connectors for industrial automation

-

Custom plug-in terminals for compact devices and LED drivers

These manufacturers operate under UL, CE, RoHS, and ISO9001 systems, aligning their products with global compliance requirements while maintaining flexible OEM capabilities for global clients.

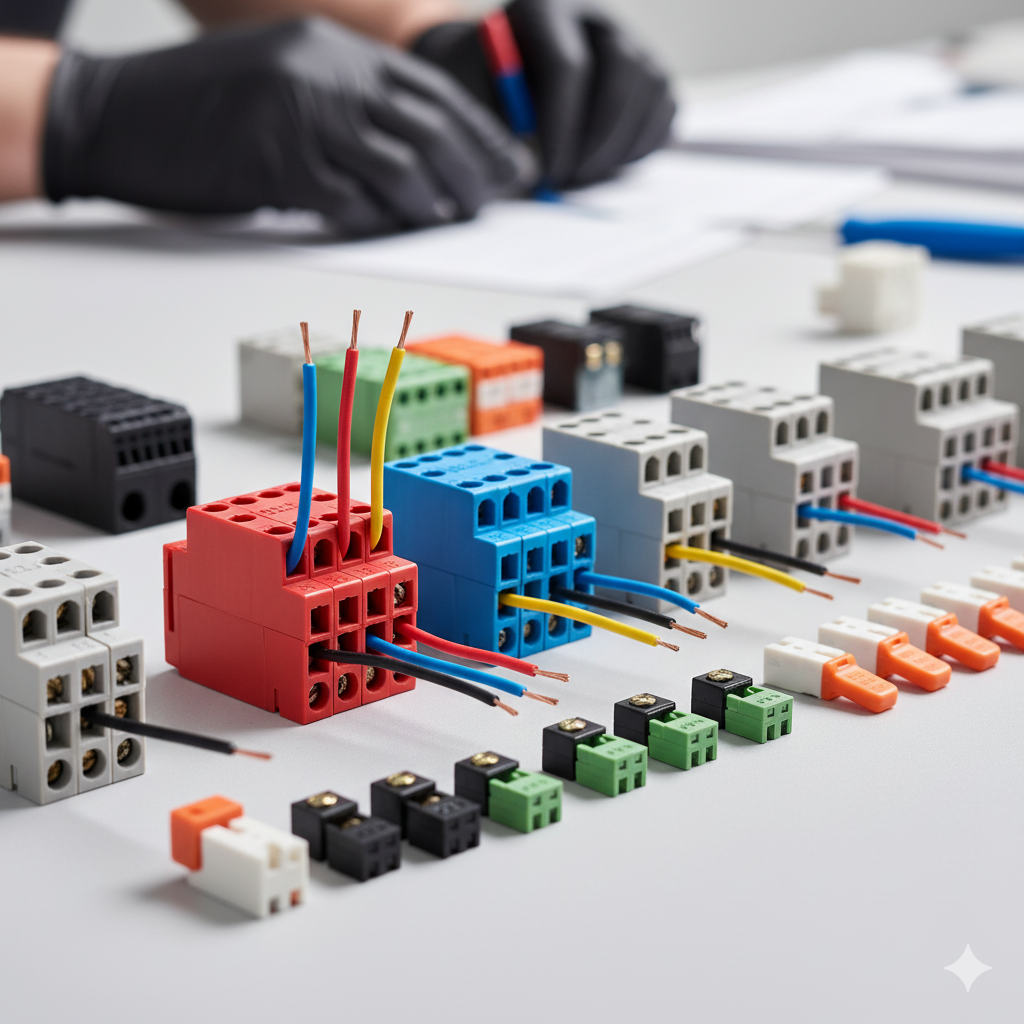

Engineering Principles Behind Reliable Terminal Block Manufacturing

The foundation of quality in Chinese-made terminal blocks lies in controlled materials and precision tooling.

| Engineering Aspect | Standard Specification | Impact on Performance |

|---|---|---|

| Housing Material | UL94 V-0 PA66 / PBT | Flame-retardant and stable under heat |

| Metal Contact | Nickel-plated brass / copper | High conductivity, anti-corrosion |

| Pitch Options | 2.54mm to 10.16mm | Compatibility with PCB and control boards |

| Temperature Range | -40°C to +125°C | Suitable for harsh environments |

| Testing Standard | UL1059 / IEC60947 | Ensures long-term electrical safety |

This combination ensures terminals resist thermal expansion, vibration, and oxidation — critical for industrial, solar, and HVAC systems that operate continuously under load.

Local vs. Global Supply Capabilities

| Criteria | Domestic Chinese Supplier | Overseas Competitor |

|---|---|---|

| Tooling Lead Time | 3–5 days | 7–10 days |

| Customization Flexibility | High (OEM/ODM support) | Limited |

| Cost Efficiency | 20–40% lower | Higher labor costs |

| Certification Coverage | UL / CE / TUV / ISO | Varies by region |

| Production Capacity | 100k–500k pcs/day | Often smaller scale |

This balance between speed, customization, and compliance makes China’s suppliers not just vendors, but engineering partners for global control system designers and distributors.

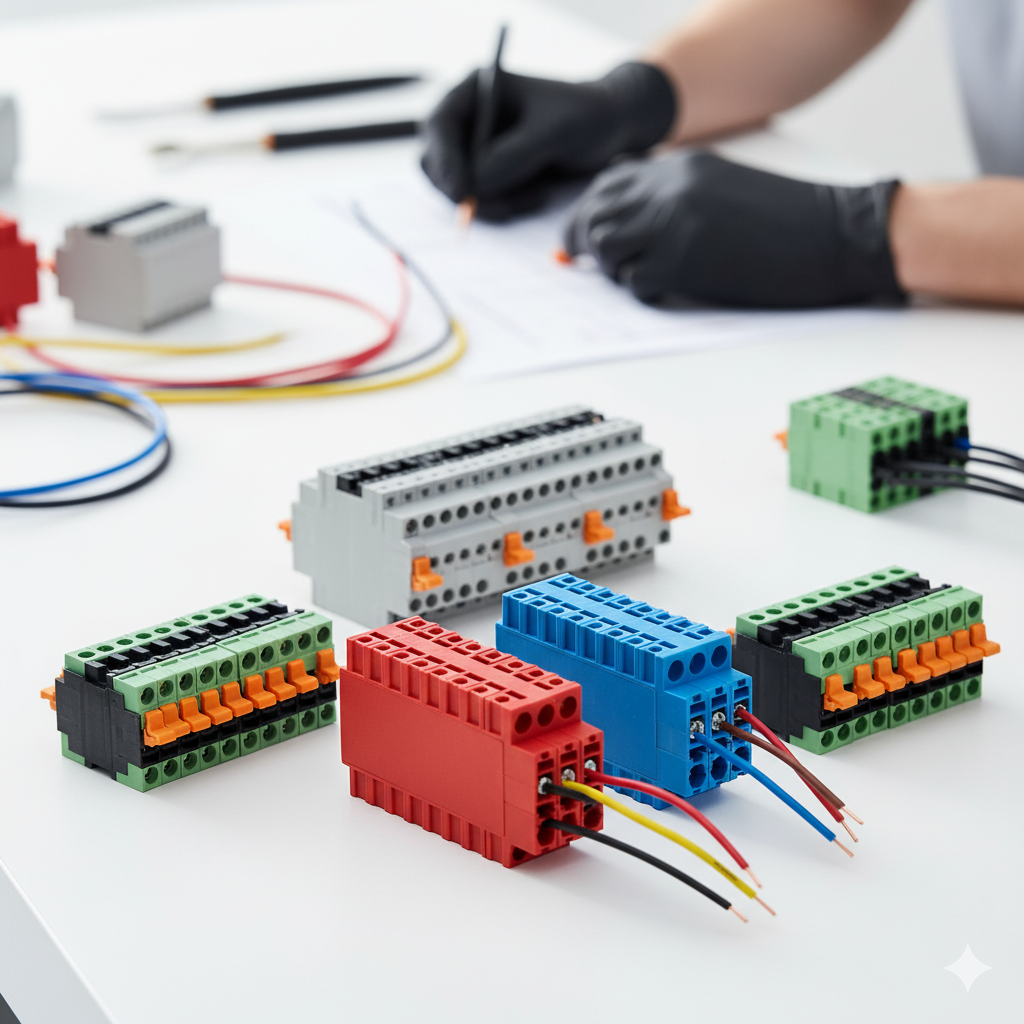

Applications Across Modern Industries

Chinese terminal block suppliers serve a wide range of sectors requiring secure, modular electrical interfaces:

-

Industrial automation: PLC wiring, relay control, and machine I/O modules

-

Energy systems: solar inverters, storage batteries, and 1000V DC combiner boxes

-

HVAC and building systems: fan controllers, thermostats, and contactors

-

Transportation: EV charging, rail systems, and onboard control units

-

Lighting electronics: LED drivers, dimmers, and smart home devices

By standardizing across IEC and UL-rated models, these terminals support global export-ready wiring systems without adaptation issues.

Selecting the Right Supplier for Your Project

Choosing a terminal block supplier in China should focus on more than just price.

Look for manufacturers who:

-

Offer complete datasheets and UL file verification

-

Maintain automated production lines for consistency

-

Provide OEM/ODM service with fast mold adjustments

-

Use third-party test certifications (SGS / TUV) for export readiness

-

Ensure on-time logistics through coastal ports (Ningbo, Shanghai, Shenzhen)

These factors guarantee both product quality and smooth project execution from sample to shipment.

Common Questions from Global Buyers

Q1: How do I verify if a Chinese supplier is UL-certified?

A: Request their UL file number and check it directly on the UL Product iQ database.

Q2: Can Chinese suppliers meet custom voltage or pitch requirements?

A: Yes, most manufacturers provide full mold customization from 2.54mm to 10.16mm pitch.

Q3: Are Chinese terminals compatible with European and American wiring systems?

A: Yes. Reputable factories produce terminals certified under UL1059, IEC60947, and EN60998 standards.

Q4: What minimum order quantities apply?

A: Typically 1000–3000 units, but most suppliers support prototype sampling for new projects.

Connecting Global Standards with Local Expertise

Today’s industrial world depends on secure, scalable wiring systems — and China’s suppliers have become a trusted foundation for that reliability.

With consistent manufacturing standards, UL-certified materials, and OEM flexibility, Zhongbo continues to deliver terminal block solutions trusted by control system builders and energy developers worldwide.

For technical details or partnership inquiries, visit our homepage or contact us.