Pluggable Terminal Block Supplier: Enhancing Connectivity and Efficiency

Modern industrial systems demand both performance and flexibility. In environments where quick installation, modular design, and safe disconnection are essential, the pluggable terminal block supplier plays a vital role. These suppliers provide the interface between control modules, power systems, and automation devices—helping industries build more efficient, serviceable, and scalable systems.

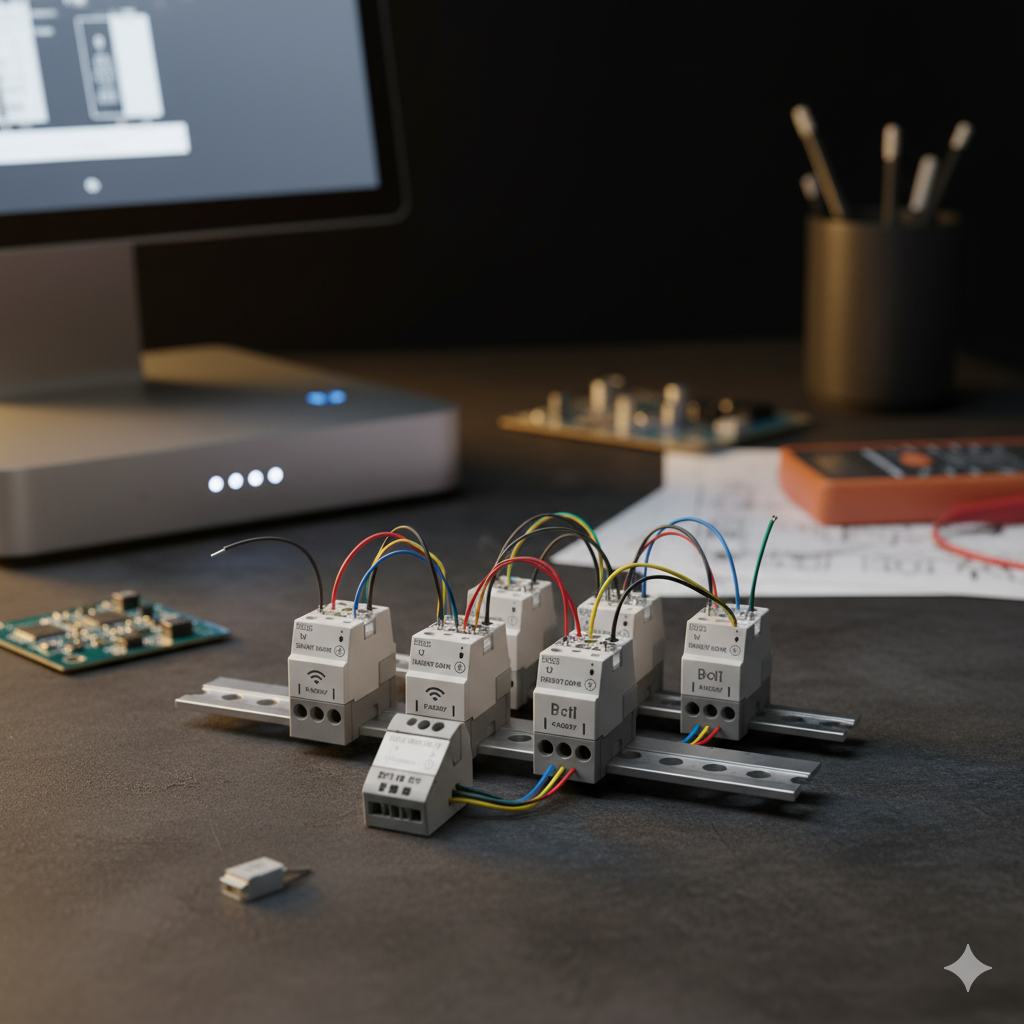

Modular Design for Smarter Industrial Wiring

Unlike traditional fixed terminals, pluggable terminal blocks use male and female connectors that allow wiring sections to be quickly detached or replaced without disturbing the rest of the circuit. This modular design simplifies maintenance and accelerates equipment installation.

Common applications include:

-

Automation control panels requiring frequent upgrades or sensor replacement

-

Renewable energy systems with modular power modules

-

Industrial equipment maintenance where downtime must be minimized

-

Testing systems that rely on plug-in flexibility for configuration changes

Such designs reduce wiring complexity and support a cleaner, more structured electrical layout—crucial for industrial automation and distributed control systems.

Engineering Behind High-Performance Plug-in Connections

Precision and durability define the performance of pluggable terminal blocks. Inside every connector, metal contact points, spring clips, and insulators work together to maintain secure and stable connections.

Professional suppliers ensure:

-

High-conductivity copper alloy contacts for minimal resistance and energy loss

-

Anti-vibration locking design to prevent accidental disconnection

-

Flame-retardant housings for improved fire resistance and safety

-

Multiple pitch and pole options for design flexibility

-

Temperature and torque testing to guarantee long-term reliability

By integrating automated production lines and CNC tooling, factories maintain consistency across thousands of components—meeting the demands of high-volume OEM and export orders.

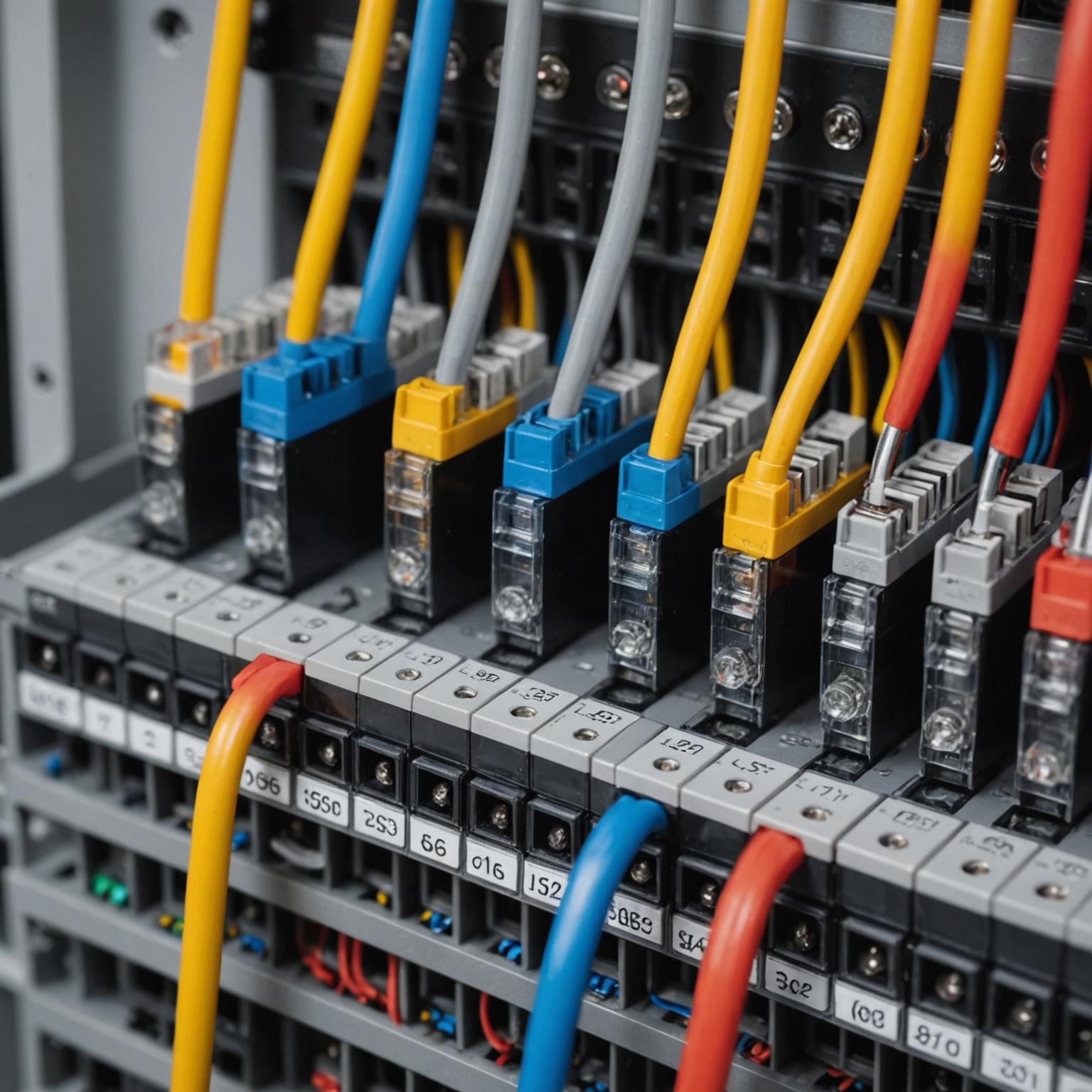

Boosting Efficiency in Power and Control Applications

Time efficiency is critical for electrical engineers and integrators. Pluggable terminals dramatically shorten installation time, especially in power distribution cabinets, control enclosures, and signal systems where repetitive wiring is common.

Advantages include:

-

Faster field replacement—no need to unscrew or rewire entire panels

-

Simplified testing and troubleshooting

-

Enhanced design flexibility in compact control modules

-

Reusable connector systems for environmentally sustainable operations

This efficiency not only cuts labor costs but also improves operational uptime—an essential factor in manufacturing and automation industries.

Customization and OEM Capabilities

Leading suppliers offer OEM connector solutions tailored to specific voltage ratings, current capacity, and environmental conditions.

Customization may include:

-

Modified housing colors or labeling for easy identification

-

Different connection angles (vertical, right-angle, or horizontal)

-

Coding and keying systems to avoid misconnection

-

Compatibility with DIN rail or PCB mounting standards

OEM flexibility allows system integrators to seamlessly integrate terminal blocks into their own branded control systems or global product platforms.

Quality, Certification, and Global Standards

As electrical safety regulations tighten worldwide, suppliers must ensure every component complies with CE, RoHS, and UL standards. High-quality products undergo strict endurance testing, including insulation resistance, heat aging, and vibration validation.

Manufacturers equipped with ISO9001-certified systems can provide traceability and performance documentation for each batch—essential for international partners in automation, renewable energy, and equipment manufacturing sectors.

Partnering with Zhongbo for Reliable Plug-in Connections

In modern power systems, reliability depends on precision at every connection point. A trusted pluggable terminal block supplier provides the flexibility, safety, and scalability industrial clients rely on.

Zhongbo continues to lead with automated manufacturing, certified quality assurance, and complete plug-in terminal block solutions tailored for automation, energy, and control systems worldwide.

To explore technical specifications or start an OEM collaboration, visit our homepage or contact us for more information.